Ultra-high pressure discharge lamp unit and light source apparatus

A technology of light source device and discharge lamp, which is applied in the direction of discharge lamp, gas discharge lamp, cooling/heating device of lighting device, etc. The effect of suppressing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

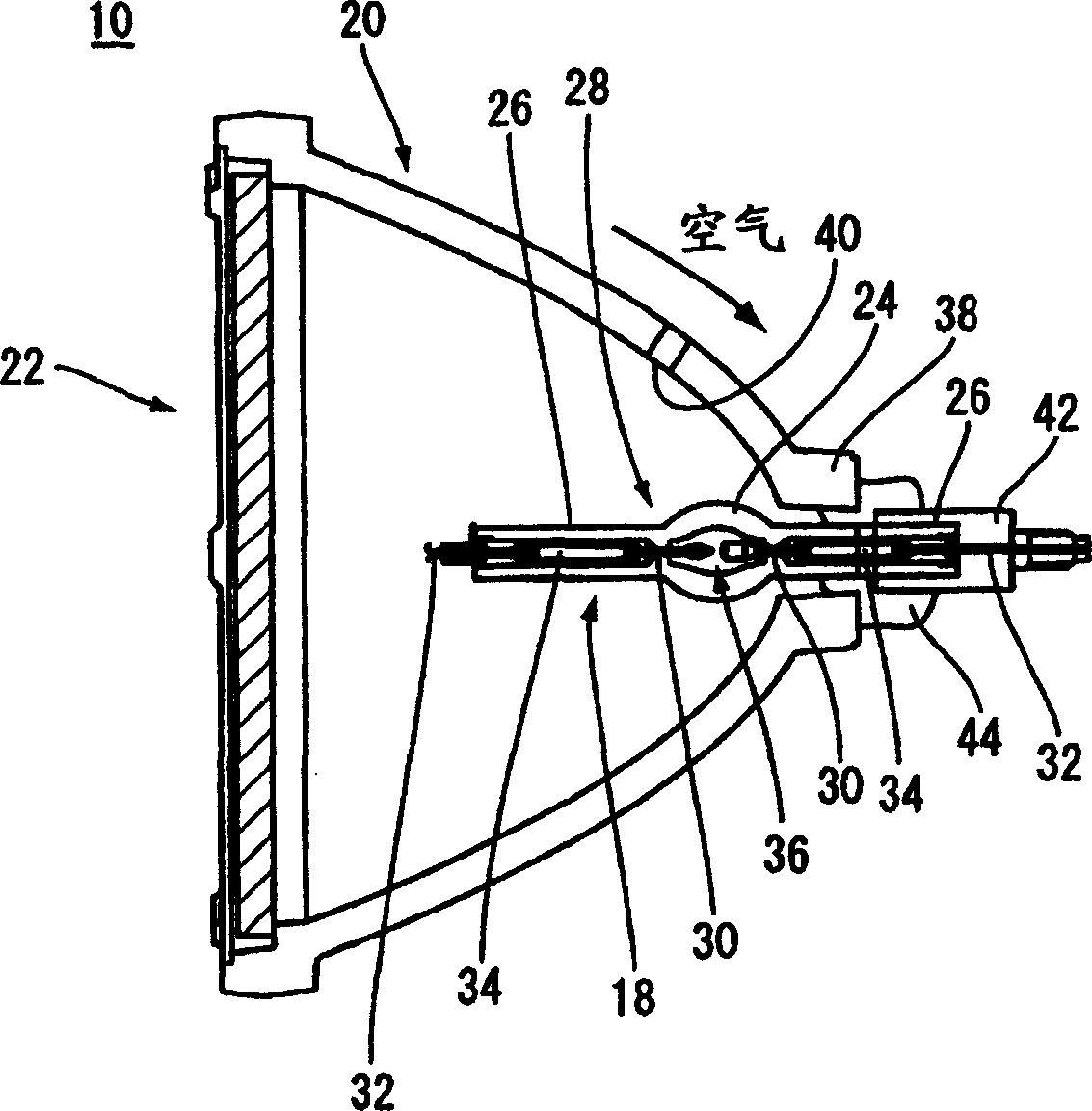

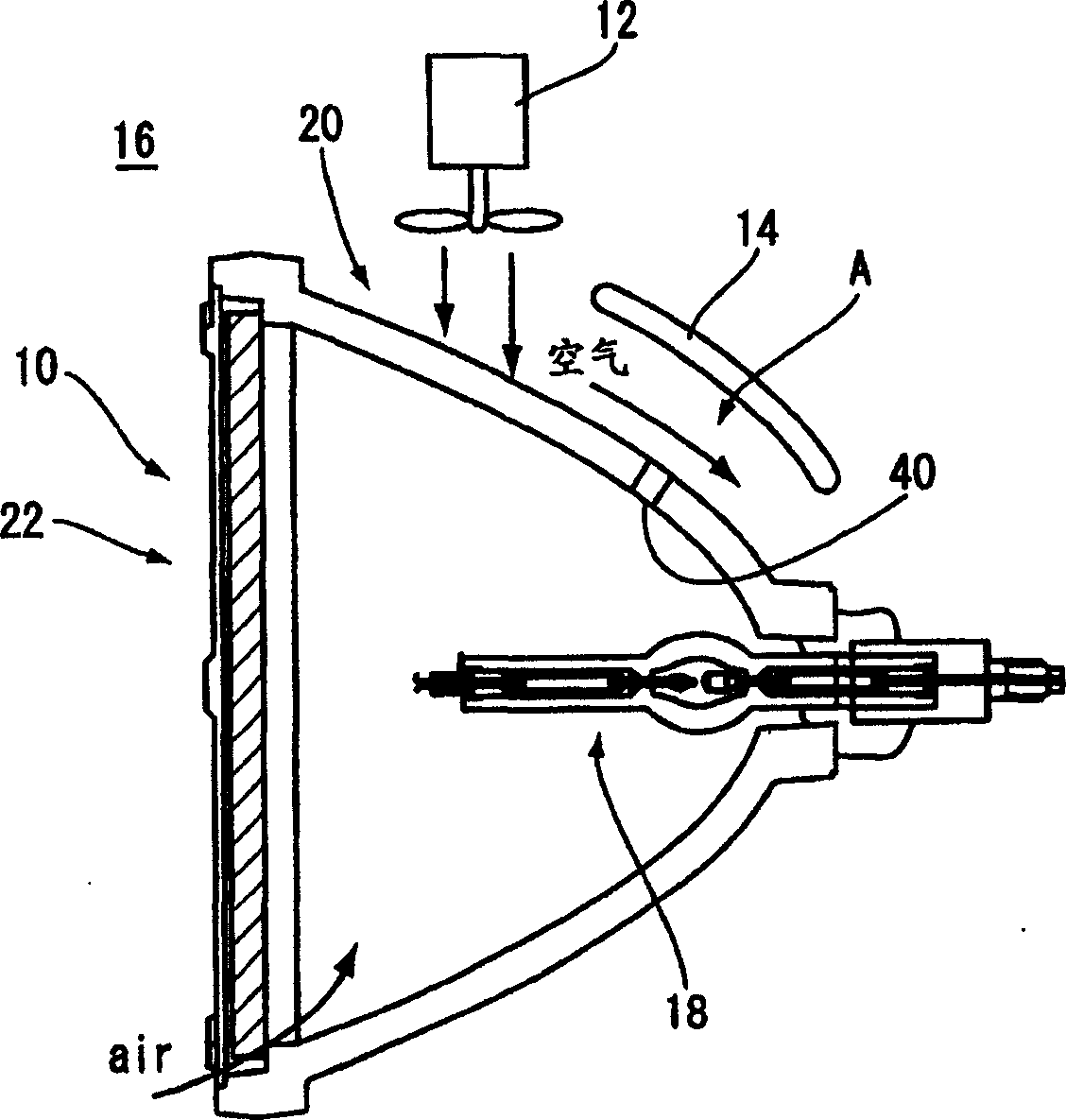

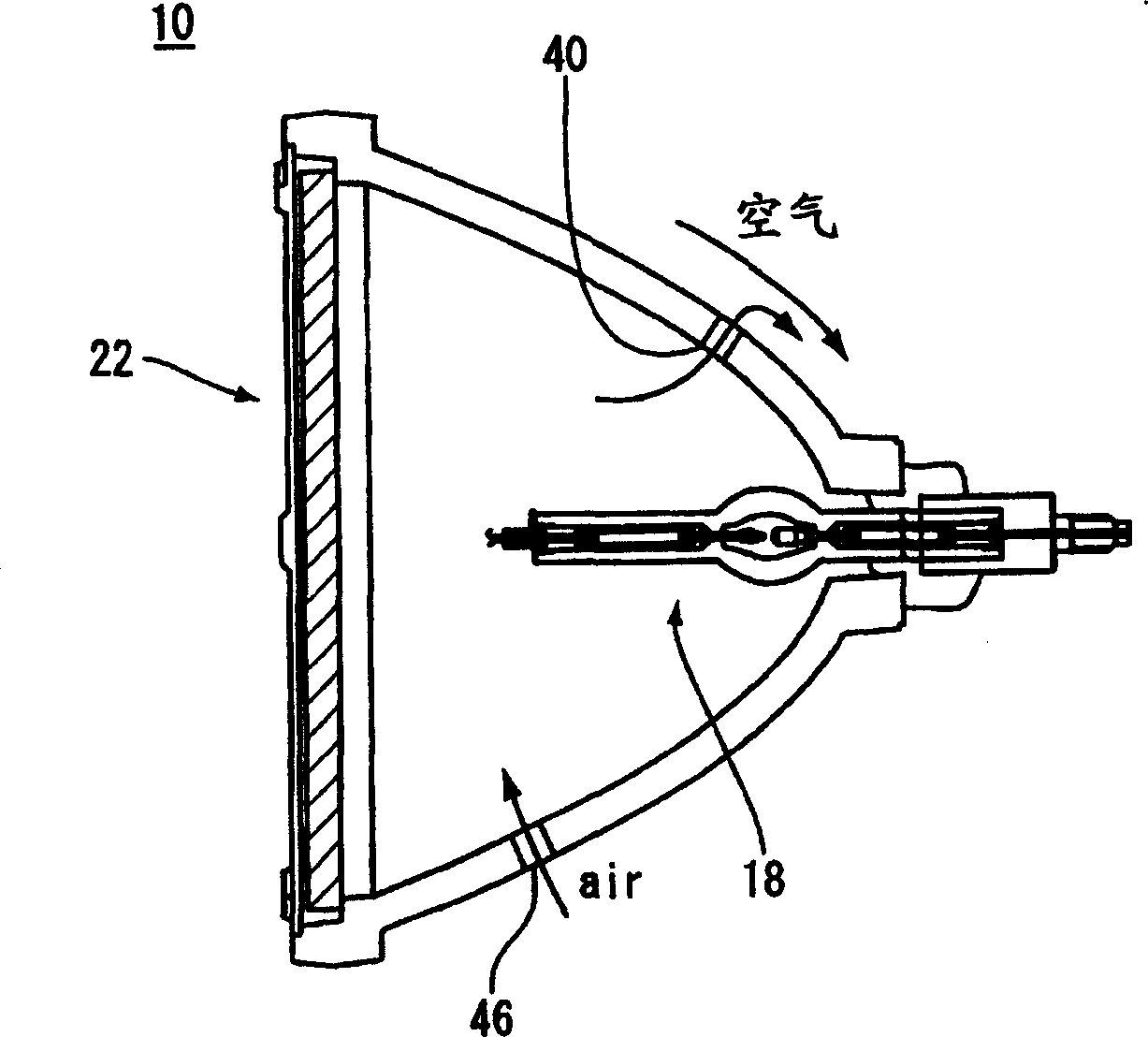

[0031] figure 1 The ultra-high pressure discharge lamp device 10 in, such as figure 2 As shown, a light source device 16 of a projection projector is formed in cooperation with a blower 12 and an air duct 14 , and has an ultra-high pressure discharge lamp 18 , a reflector 20 for reflecting light from the ultra-high pressure discharge lamp 18 , and a cover 22 .

[0032] Ultra-high pressure discharge lamps 18 such as figure 1 As shown, a discharge vessel 28 made of quartz glass comprising a spherical light-emitting portion 24 and a rod-shaped sealing portion 26 extending straight from both ends of the light-emitting portion 24, each sealing portion 26 is provided with an electrode rod 30, a lead rod 32 and a The molybdenum sheets 34 which are connected electrically have tungsten electrodes 36 between the ends of the electrode rods 30 in the light emitting part 24 . 0.15mg / mm 3 Above high pressure mercury, rare gases and halogens.

[0033] The size of the ultra-high pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com