Production of visible light composite catalyst for high-efficient decontamination antibacterial

A composite catalyst and visible light technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficult control, complicated synthesis steps, and inability to control the amount of nitrogen doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical characteristics and advantages of the present invention can be seen through the embodiments and application examples given below.

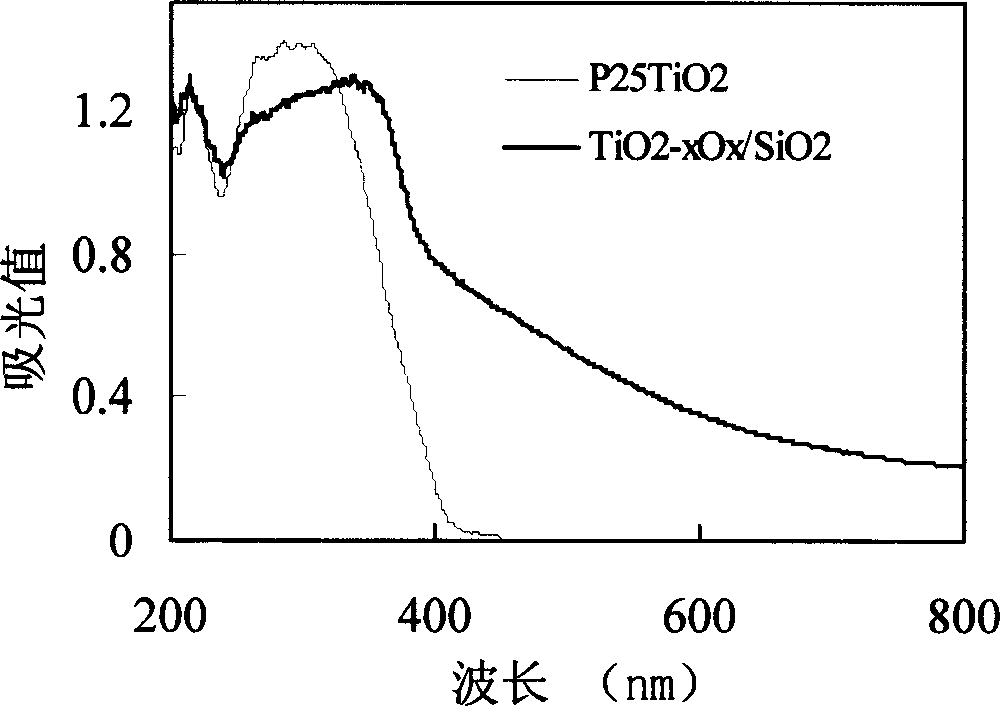

[0012] 1. Nitrogen-doped composite photocatalyst TiO 2-x N x / SiO 2 The optical absorption characteristic of photocatalyst tetrabutyl titanate and the volume ratio of hexanaphthene are 1: 3, then add ethylenediamine, make the molar ratio of nitrogen and oxygen in titanium oxide be respectively 8%, dry porous silica gel Immerse in the above organic solution and react for 15 hours, then evaporate the cyclohexane at 40°C, dry the sample at 100°C, calcinate in the furnace at 400°C for 8 hours, and then cool naturally in the furnace to room temperature to obtain deep Yellow material, the catalyst was characterized by UV-Vis diffuse reflectance spectroscopy, proving that TiO 2-x o x / SiO 2 There is absorption in the visible light region (400-600nm) ( figure 1 ).

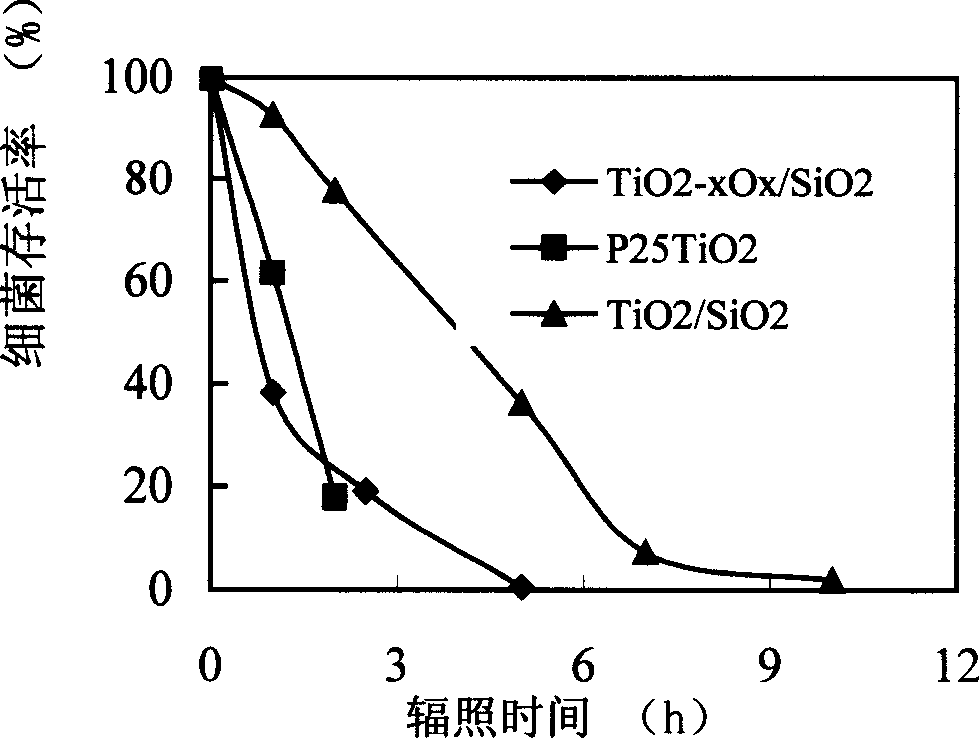

[0013] 2. TiO2 2-x o x / SiO 2 Photocatalytic Activity for P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com