Three-dimensional structure sulfur-nitrogen codope hierarchical pore graphene and preparation method thereof

A three-dimensional structure and co-doping technology, applied in the field of carbon nanomaterials, can solve the problems of high toxicity, high production cost, difficulty in effectively controlling the position and type of heteroatom doping, etc., and achieve the effect of simple process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) First, 6mmol Mg(NO 3 ) 2 ·6H 2 O, 2mmol Al(NO 3 ) 3 9H 2 O and 16mmol hexamethylenetetramine were mixed and dissolved in 20mL de-carbonated deionized water to prepare a mixed solution; then 20mmol m-sulfanilic acid and 20mmol NaOH were dissolved in 20mL de-carbonated deionized water for neutralization reaction, Sodium m-aminobenzenesulfonate solution was obtained. Under the protection of nitrogen, the above mixed solution and sodium m-aminobenzenesulfonate solution were mixed, stirred evenly, transferred to a 50mL polytetrafluoroethylene-lined autoclave, and placed in an oven at 100°C for 12 hours at a constant temperature. Take out the autoclave and let it cool down to room temperature naturally, filter and wash the filtrate with 800mL deionized water and 200mL ethanol until the pH value of the filtrate is 7, then dry the filter cake at 80°C for 8 hours to obtain the magnesium aluminum hydrotalcite.

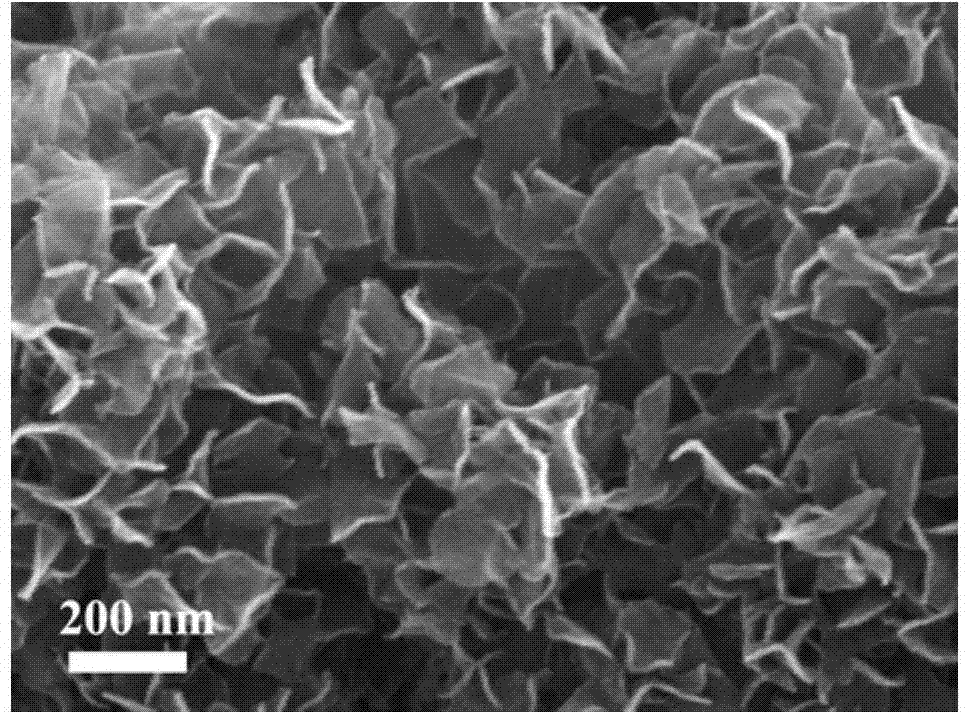

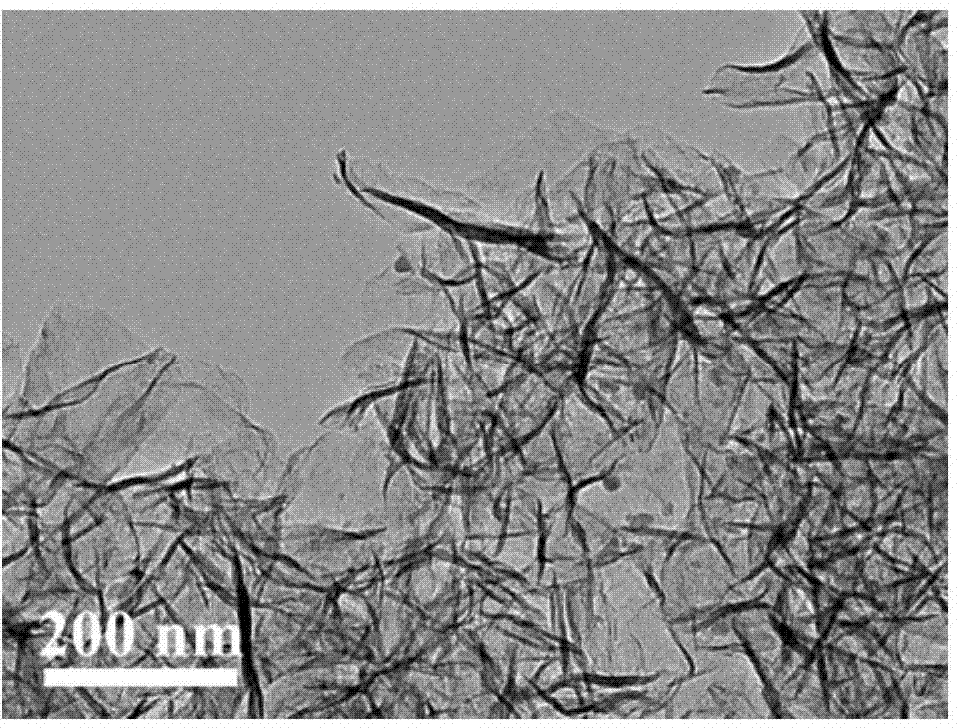

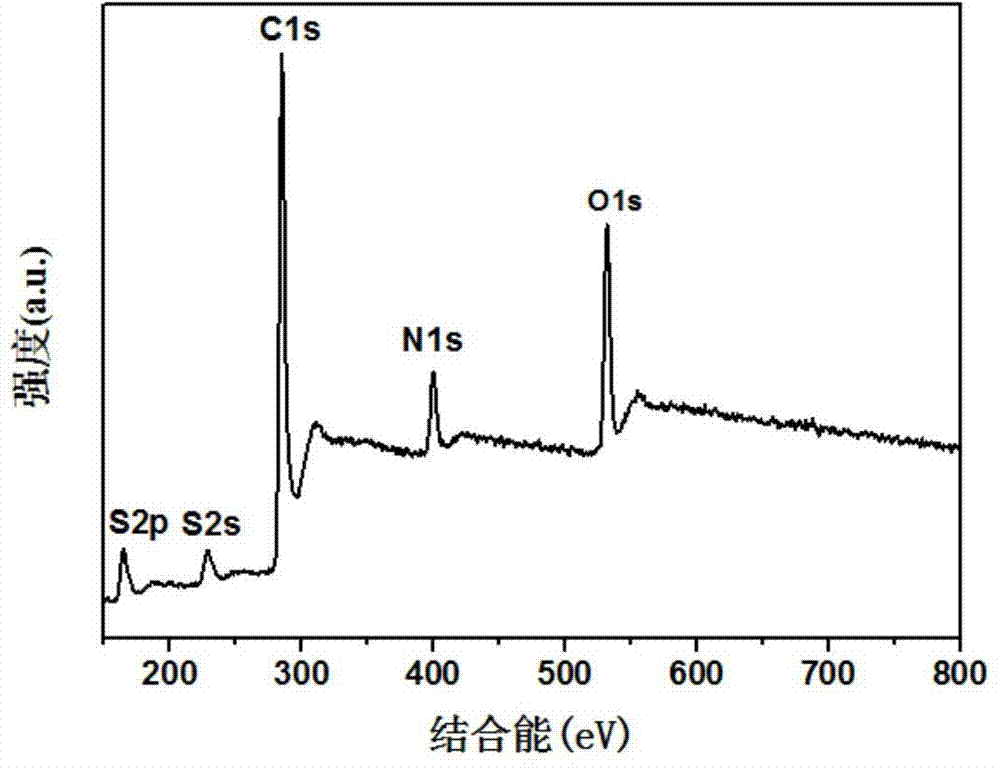

[0024] (2) Put the magnesium-aluminum hydrotalcite interc...

Embodiment 2

[0028] (1) First, 10mmol CoSO 4 ·7H 2 O, 4mmol Al(NO 3 ) 3 9H 2 O and 28mmol hexamethylenetetramine were mixed and dissolved in 20mL of de-carbonated deionized water to prepare a mixed solution; then 30mmol of sulfanilic acid and 30mmol NaOH were dissolved in 20mL of de-carbonated de-ionized water for neutralization reaction, Sodium m-aminobenzenesulfonate solution was obtained. Under the protection of nitrogen, mix the above mixed solution and sodium m-aminobenzenesulfonate solution, stir evenly, transfer it to a 50mL polytetrafluoroethylene-lined autoclave, put it in an oven at 120°C for 10 hours, and take it out The autoclave was naturally cooled to room temperature, filtered and washed with 800mL deionized water and 200mL ethanol until the pH value of the filtrate was 7.5, and then the filter cake was air-dried at 70°C for 12 hours to obtain the magnesium aluminum intercalated with m-aminobenzenesulfonate Hydrotalcite.

[0029] (2) Put the above-mentioned sulfanilate...

Embodiment 3

[0032] (1) First, 5.6mmol MgCl 2 ·6H 2 O, 1.6 mmol AlCl 3 ·6H 2 O and 14.4mmol of hexamethylenetetramine were mixed and dissolved in 20mL of de-carbonated deionized water to prepare a mixed solution; then 20mmol of sulfanilic acid and 20mmol of NaOH were dissolved in 20mL of de-carbonated de-ionized water for neutralization , to obtain sodium p-aminobenzenesulfonate solution. Under the protection of nitrogen, mix the above mixed solution and sodium p-aminobenzenesulfonate solution, stir evenly, transfer to a 50mL polytetrafluoroethylene-lined high-pressure reactor, put it in an oven at 90°C for 20 hours, and take out The autoclave was naturally cooled to room temperature, filtered and washed with 800mL deionized water and 200mL ethanol until the pH value of the filtrate was 7, and then the filter cake was air-dried at 60°C for 12 hours to obtain magnesium aluminum intercalated with p-aminobenzenesulfonate Hydrotalcite.

[0033] (2) Put the p-aminobenzenesulfonate intercal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com