Production of liquid-crystal display panel and circuit substrate

A technology for liquid crystal display panels and circuit substrates, applied in static indicators, instruments, etc., can solve the problems of poor display stability, fractures, and poor contact of liquid crystal panels, avoid bad contact or fractures, and improve production quality. efficiency, ensuring the effect of electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

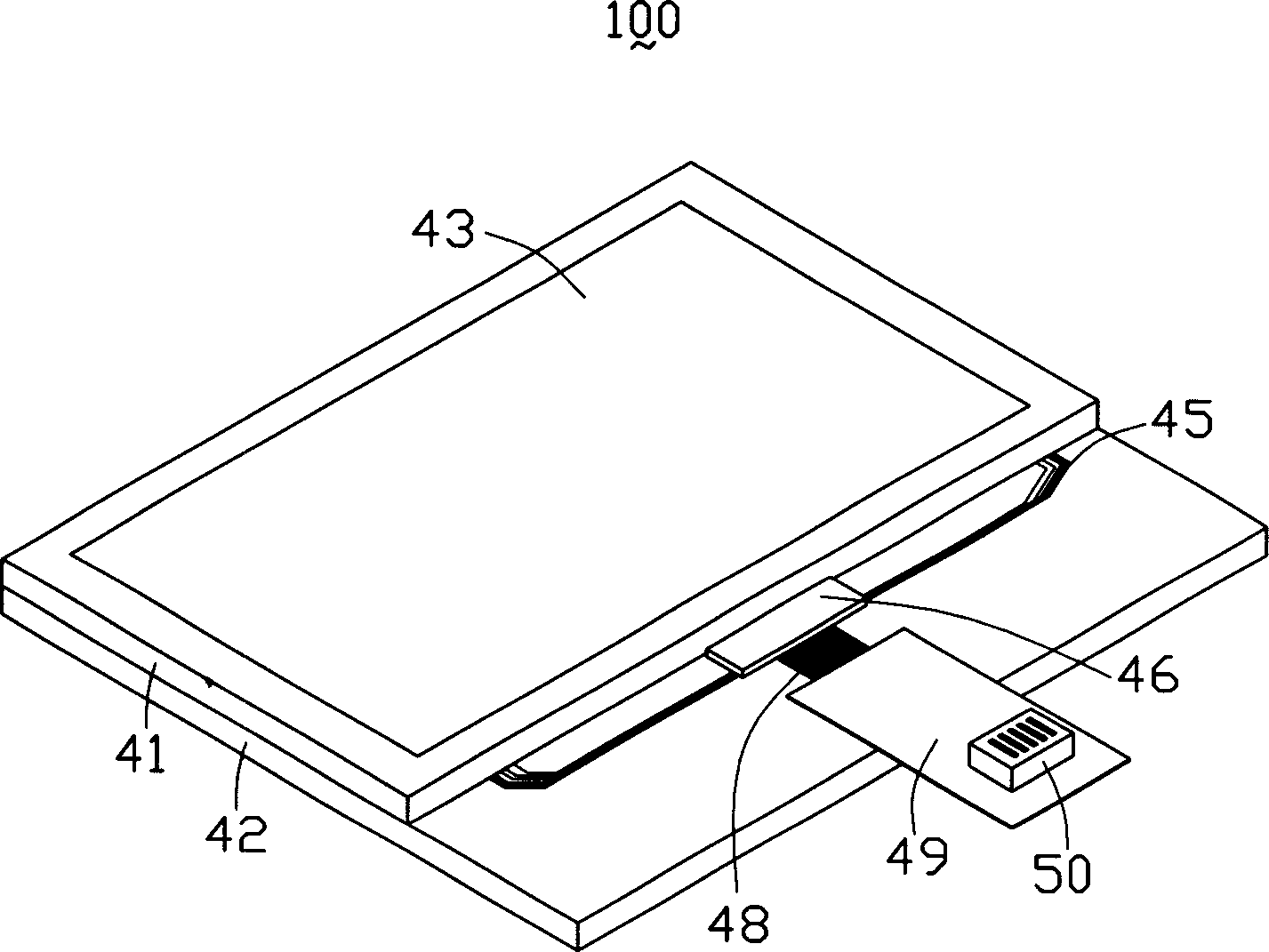

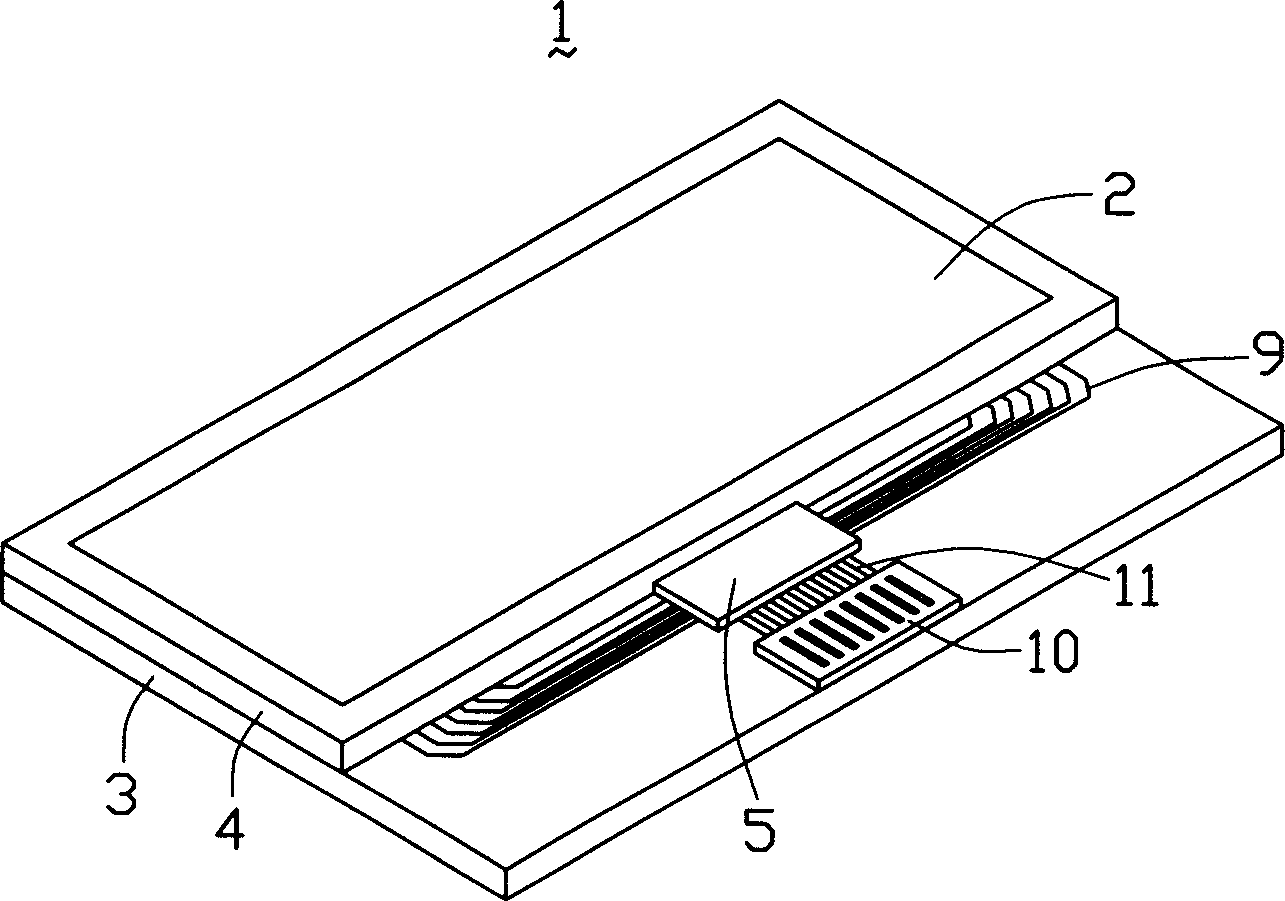

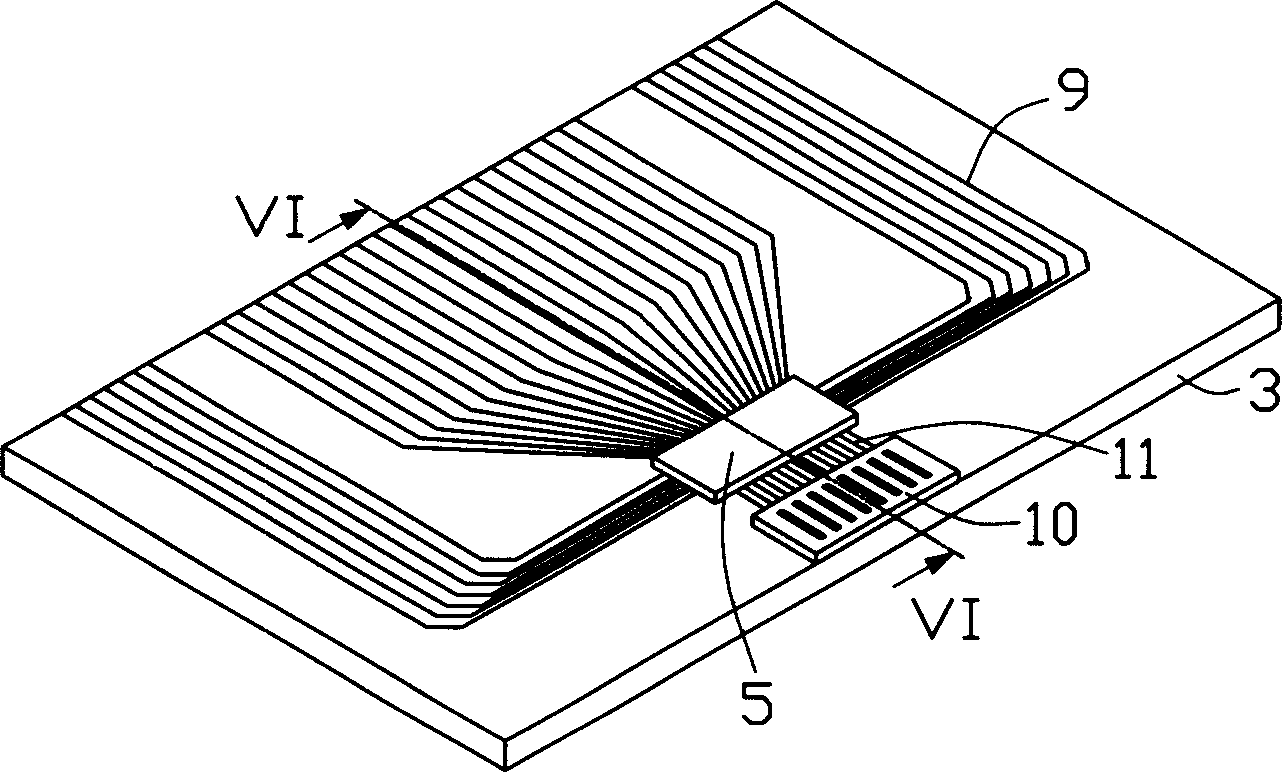

[0017] Please refer to figure 2 with image 3 , figure 2 It is a structural schematic diagram of the liquid crystal display panel of the present invention, image 3 yes figure 2 Schematic diagram of the partial structure of the second substrate in . The liquid crystal display panel 1 includes a first substrate 4 and a second substrate 3, the first substrate 4 and the second substrate 3 are superimposed on each other, and the second substrate 3 includes a driver chip 5, a connector 10, and a plurality of first wires 9 and a plurality of second wires 11. Please also refer to Figure 5 , the second substrate 3 has a connector pressing area 6, the connector 10 is located on the connector pressing area 6, and one end of the driving chip 5 passes through a plurality of first wires and a control circuit (not shown in the figure) The other end of the driver chip 5 is connected to the connector 10 through the plurality of second wires 11, and the connector 10 can be connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com