Self adaptive vacuum suction disc work bench

A vacuum suction cup and workbench technology, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve problems such as failure to work normally, failure to work, system damage, etc., and achieve the effect of widening the scope of use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

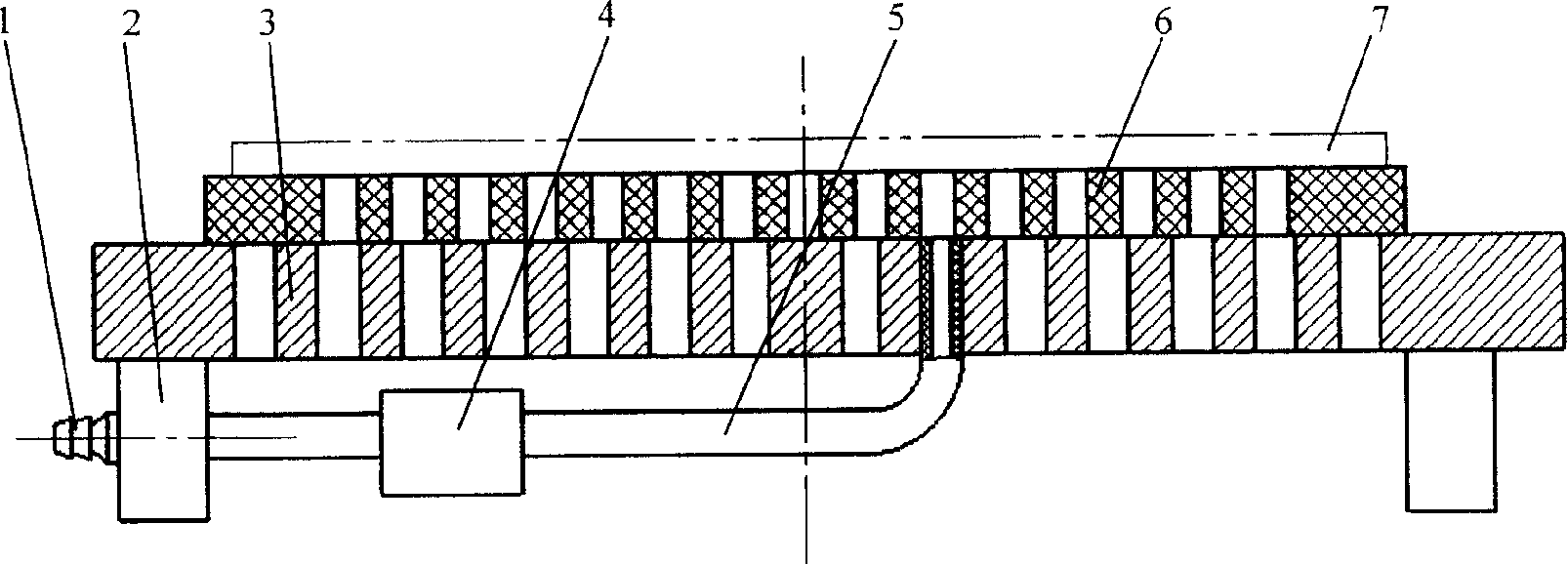

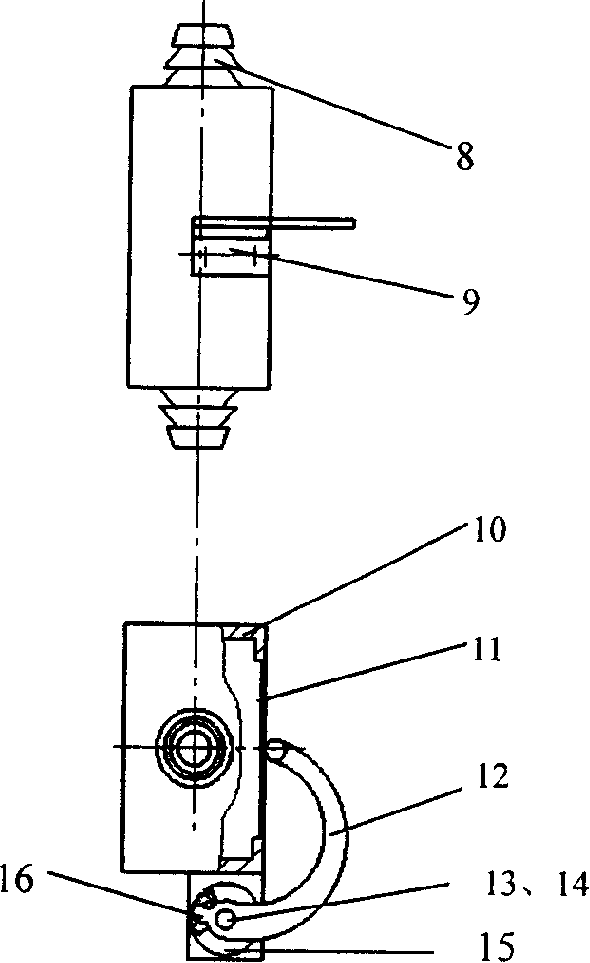

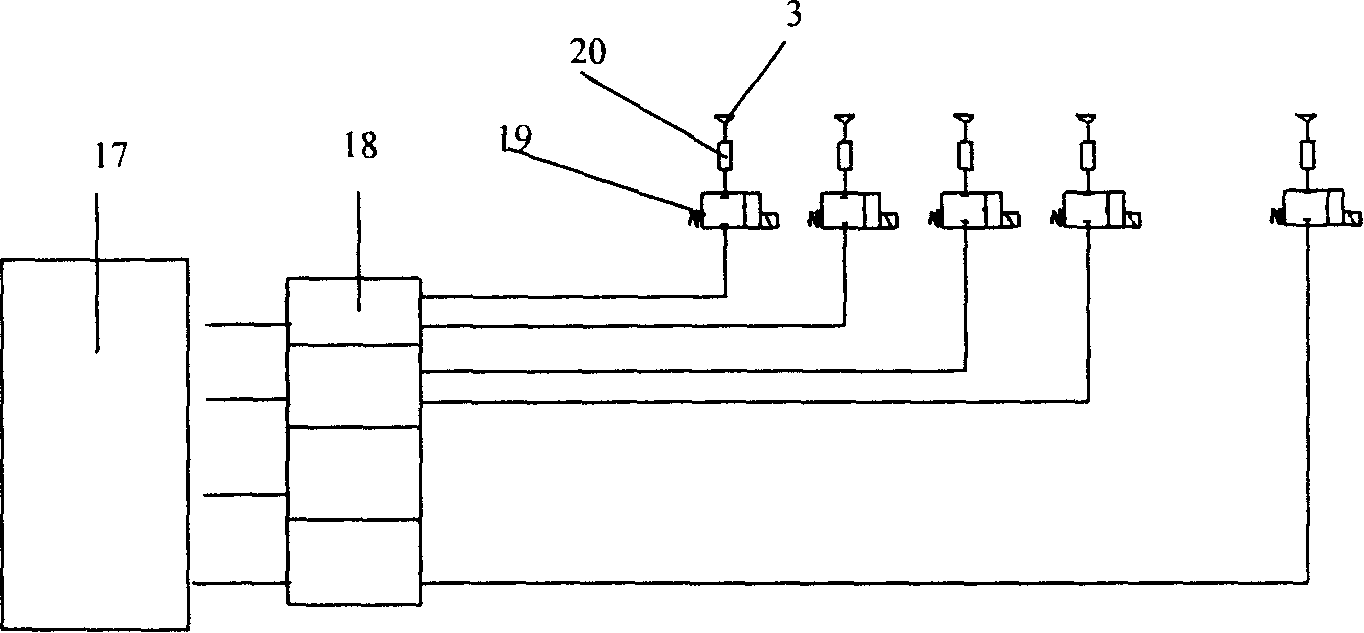

[0015] The present invention mainly consists of a double-way pipe joint 1, a suction cup base 2, a suction cup base 3, a negative pressure detector 4, a hose 5, a rubber pad 6, a workpiece 7, a pipe joint 8, a detection switch seat 9, a box body 10, an elastic Film 11, detection rod 12, pin shaft 13, torsion spring 14, switch chassis 15, contacts 16, vacuum generator 17, vacuum chamber 18, electromagnetic switch valve 19, negative pressure switch 20 and so on.

[0016] Such as figure 1 As shown: the present invention adopts the suction cup base 3 to be installed on the suction cup base 2, and a certain density of through holes is processed on the suction cup base 3, and the through holes are evenly distributed. Glue one end of the hose 5 into the through hole, the other end of the hose 5 is connected to the negative pressure detector 4, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com