Low power consumption digital controlled contact device and control system thereof

A low-power, contactor technology, applied in relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problems of restricting the application and development of control systems, poor motion controllability, short service life, etc., and achieve flexible and convenient line connection. , Significant energy saving effect, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

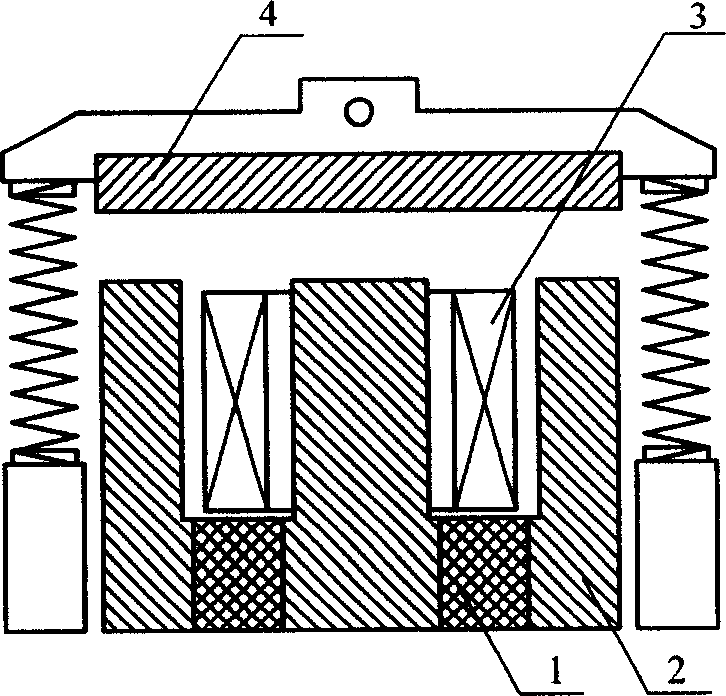

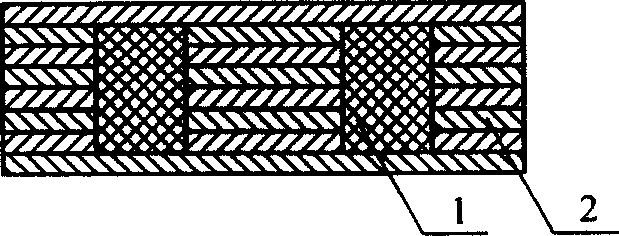

[0036] figure 1 A schematic diagram of an EI core structure is shown. In the figure, 1 is a permanent magnet; 2 is a static iron core; 3 is an excitation coil; 4 is a moving iron core. The static iron core 2 is an E-shaped structure, and the moving iron core 4 is an I-shaped structure. In this example, the core of the low-power CNC contactor is made of silicon steel sheets, such as figure 2 shown. The permanent magnet 1 is an NdFeB permanent magnet, and this example adopts a double permanent magnet structure. The permanent magnet 1 is embedded in the middle position of the groove bottom of the E-type static iron core 2 . The permanent magnet 1 is embedded in this position for processing and installation, and the mechanical strength of the static iron core will not be affected too much due to the processing of the static iron core and the installation of the permanent magnet. When in the disconnected state, the reluctance of each branch from the position of the permanent ...

Embodiment 2

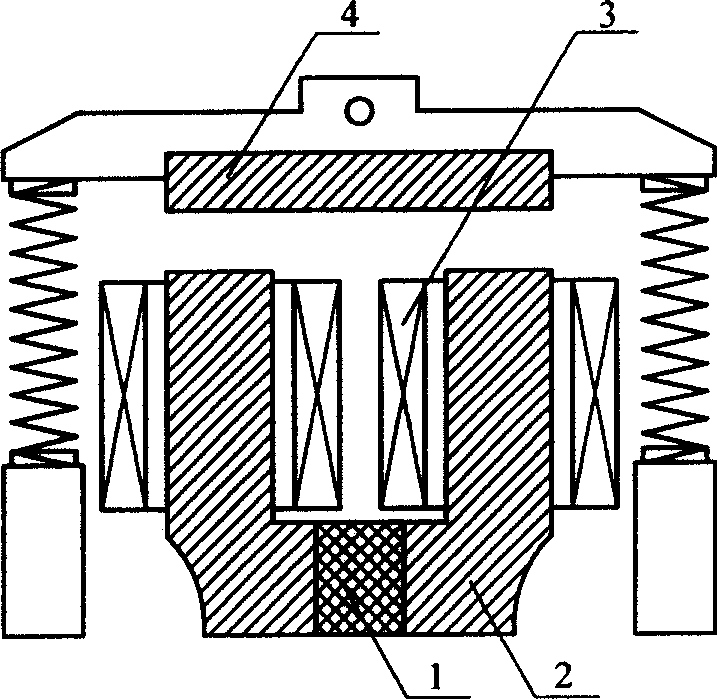

[0038] Such as image 3 As shown, the iron core structure of this example is UI-shaped, the static iron core 2 is a U-shaped structure, and the moving iron core 4 is an I-shaped structure. The permanent magnet 1 is embedded in the middle of the groove bottom of the U-shaped static iron core 2, Figure 4A transverse sectional view of the static core of this example is shown. This low-power digitally controlled contactor uses dual field coils. The UI-type core is suitable for large-scale low-power CNC contactors of 300-800A. The single permanent magnet structure in this example simplifies the design of the magnetic circuit. Parallel drive or synchronous drive of double excitation coils can effectively solve the problem of difficult start of large contactors when the nominal voltage DC24V is used, highlighting the superiority of its structure. Other structural features of this example are the same as in Example 1.

Embodiment 3

[0040] Figure 5 The schematic diagram of the driving circuit of this example is shown. The driving circuit is installed in the base of the low-power numerical control contactor, and forms a whole with the low-power numerical control contactor. Figure 5 Among them, the excitation coil KM is connected to the power supply through the transfer switch JK2 and the transfer switch JK3. The transfer switch JK2 is the contact of the relay J2, and the transfer switch JK3 is the contact of the relay J3. The charge and discharge of capacitor C5 and capacitor C6 connected in series with relay J2 and relay J3 are controlled by switch JK1-1 and switch JK1-2, and switch JK1-1 and switch JK1-2 are controlled by relay J1, and relay J1 is controlled by an external control signal. image 3 C is connected to the external control signal, Vcc is connected to the external positive power supply, and G is the common ground.

[0041] Figure 5 The medium power supply circuit has three relatively i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com