Rotor of wheel spoke type electric motor and its manufacturing method

A manufacturing method and motor technology, applied in the manufacture of stator/rotor bodies, etc., can solve problems such as difficulty in fixing, and achieve the effects of reducing production costs, increasing magnetic flux density, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

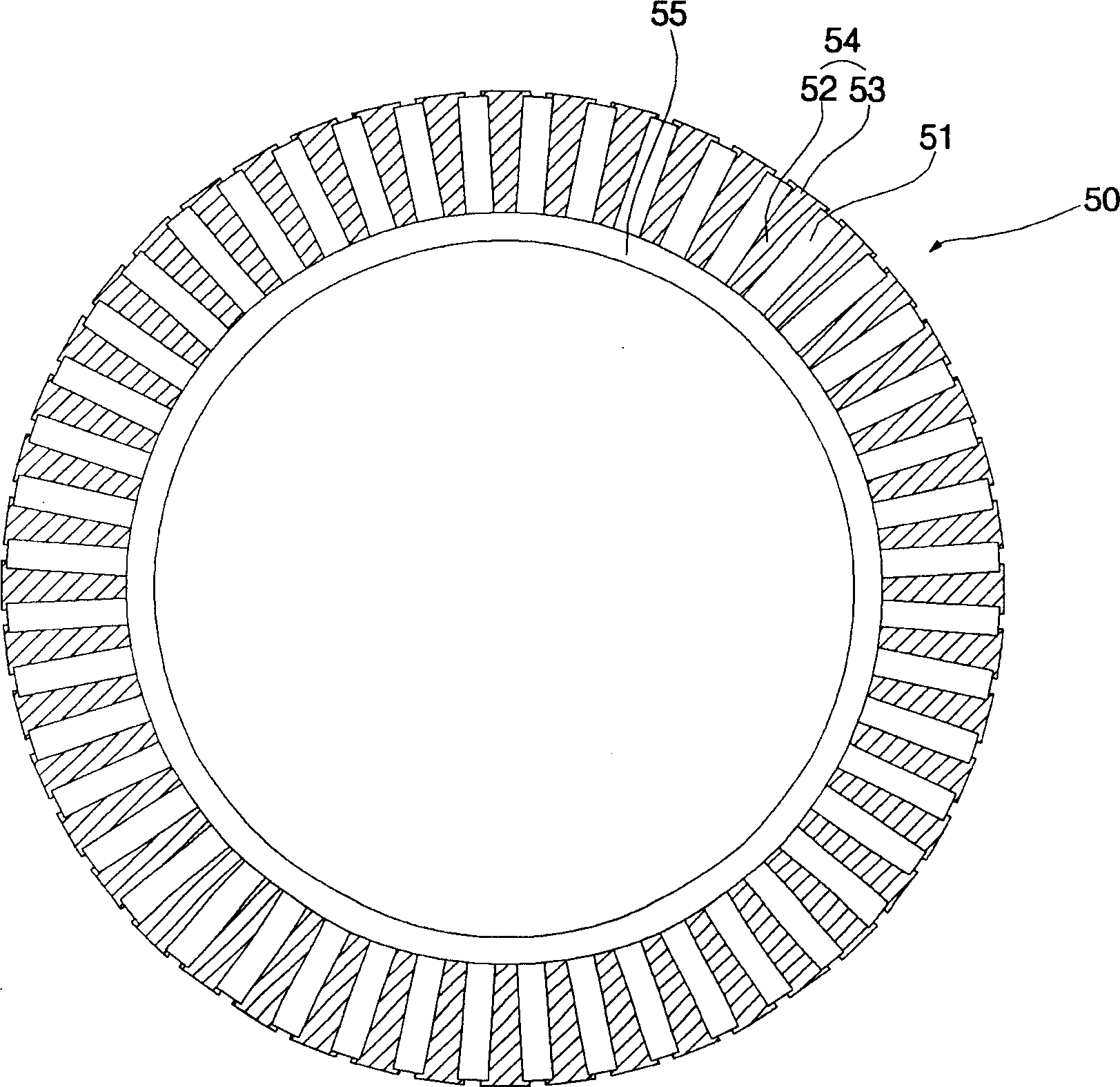

[0043] image 3 Fig. 1 is a sectional view of the spoke motor rotor according to the first embodiment of the present invention.

[0044] Utilize the rotor of the spoke type electric motor of first embodiment of the present invention, be by comprising that the center has annular non-electric conductor yoke ring 55; T-shaped pillars 54 ; and a plurality of permanent magnets 51 between adjacent rotor T-shaped pillars 54 .

[0045] The rotor T-shaped column 54 includes a radial rod 52 from the center direction of the rotor; and on the outer end side of the rod 52, a rod tail 53 forming a flange in the circumferential direction is formed, and the end face of the entire rotor T-shaped column is T-shaped.

[0046] Between adjacent rods 52 and rods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com