Engine oil lifetime monitoring apparatus for internal combustion engine

A technology for monitoring devices and internal combustion engines, applied in the direction of measuring devices, adopting mechanical devices, material inspection products, etc., can solve problems such as machine damage, errors and forgetting, and decreased lubricity, and achieve the effect of ensuring normal use and preventing errors and forgetting

- Summary

- Abstract

- Description

- Claims

- Application Information

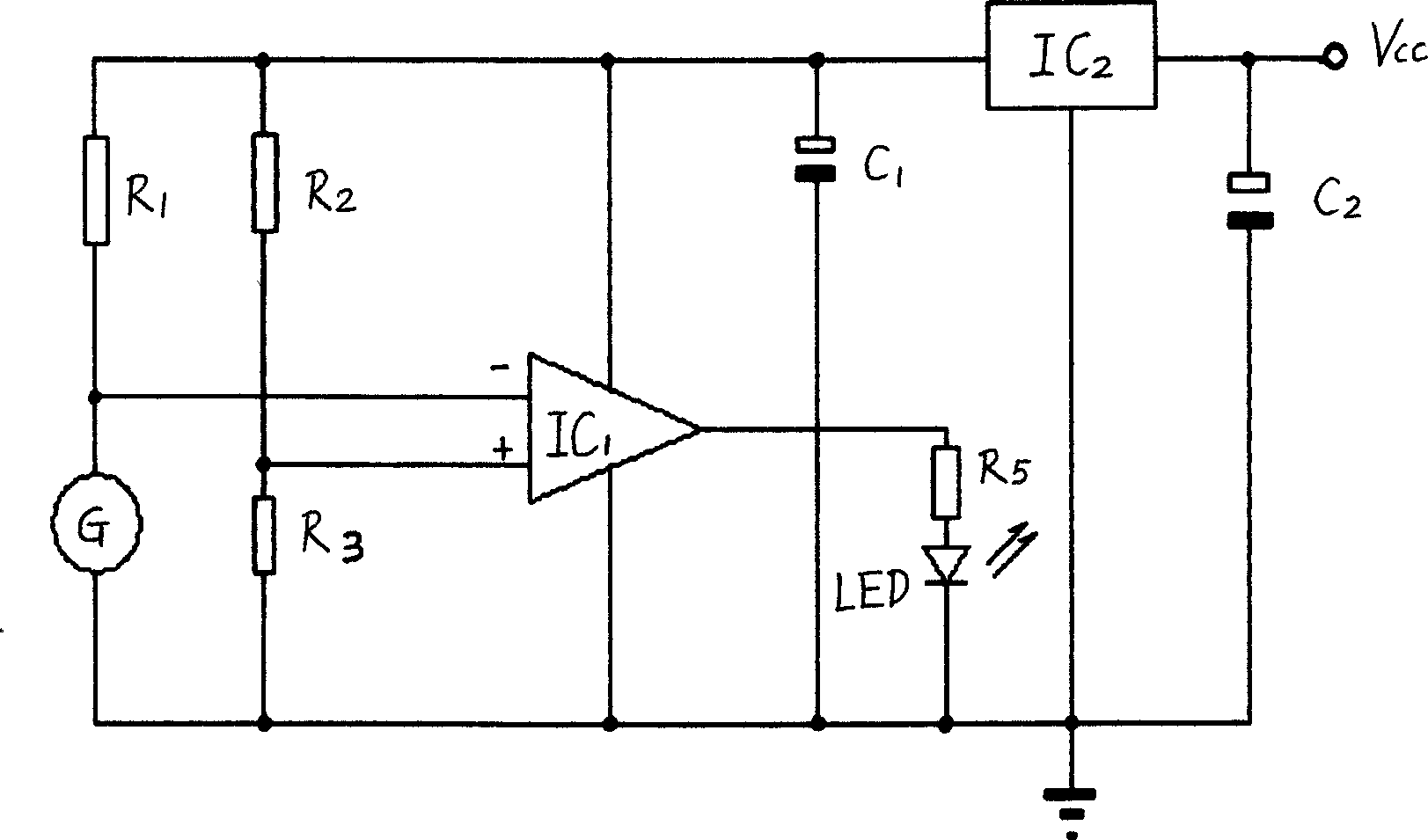

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

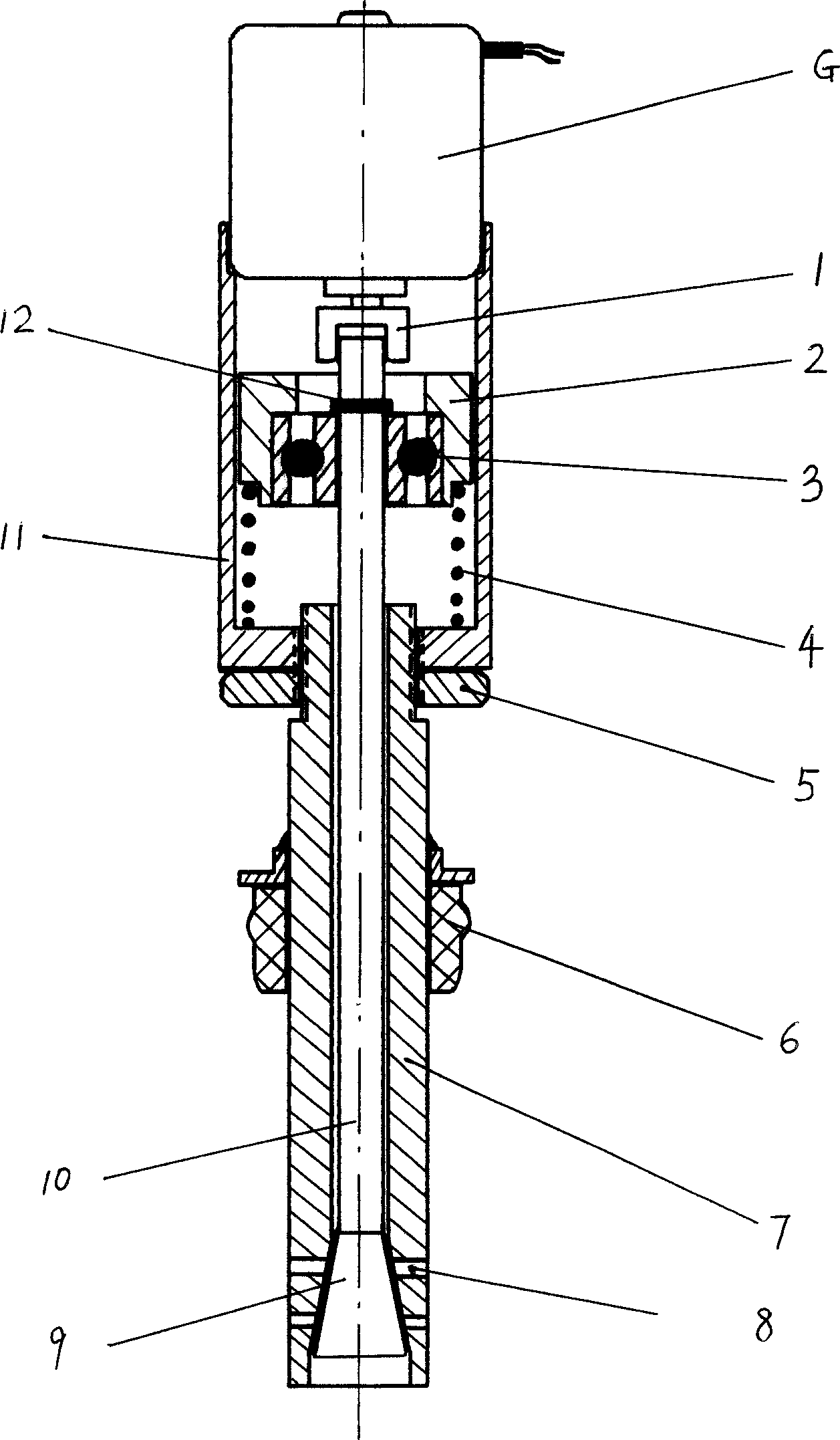

[0011] Such as figure 2 As shown, the sensor includes a motor G, a friction head 9, and a oil measuring tube 7. The friction head 9 is set in the oil measuring tube 7, and the corresponding parts of the friction head 9 and the inner wall of the oil measuring tube 7 are made into corresponding cone shapes, and the taper surfaces are matched. contact; the rotating shaft 10 of the friction head 9 is provided with a tensioning device composed of a shaft sleeve 2 and a compression spring 4, so that the friction head 9 is in close contact with the inner wall of the oil measuring tube 7, and the friction head 9 can be adjusted by adjusting the nut 5. Pulling force; the rotating shaft 10 is connected with the motor G through the coupling 1, and the contact surface between the coupling 1 and the rotating shaft 10 is made into a prism or a spline, so that it can move axially to cooperate with the adjustment of the adjusting nut 5.

[0012] During use, the sensor is inserted in the engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com