Control valve for variable displacement compressor

A technology of volumetric compressors and control valves, which is applied in the direction of liquid variable displacement machinery, variable displacement pump components, mechanical equipment, etc., and can solve the problems of damage to axial slidability, valve elements cannot move smoothly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

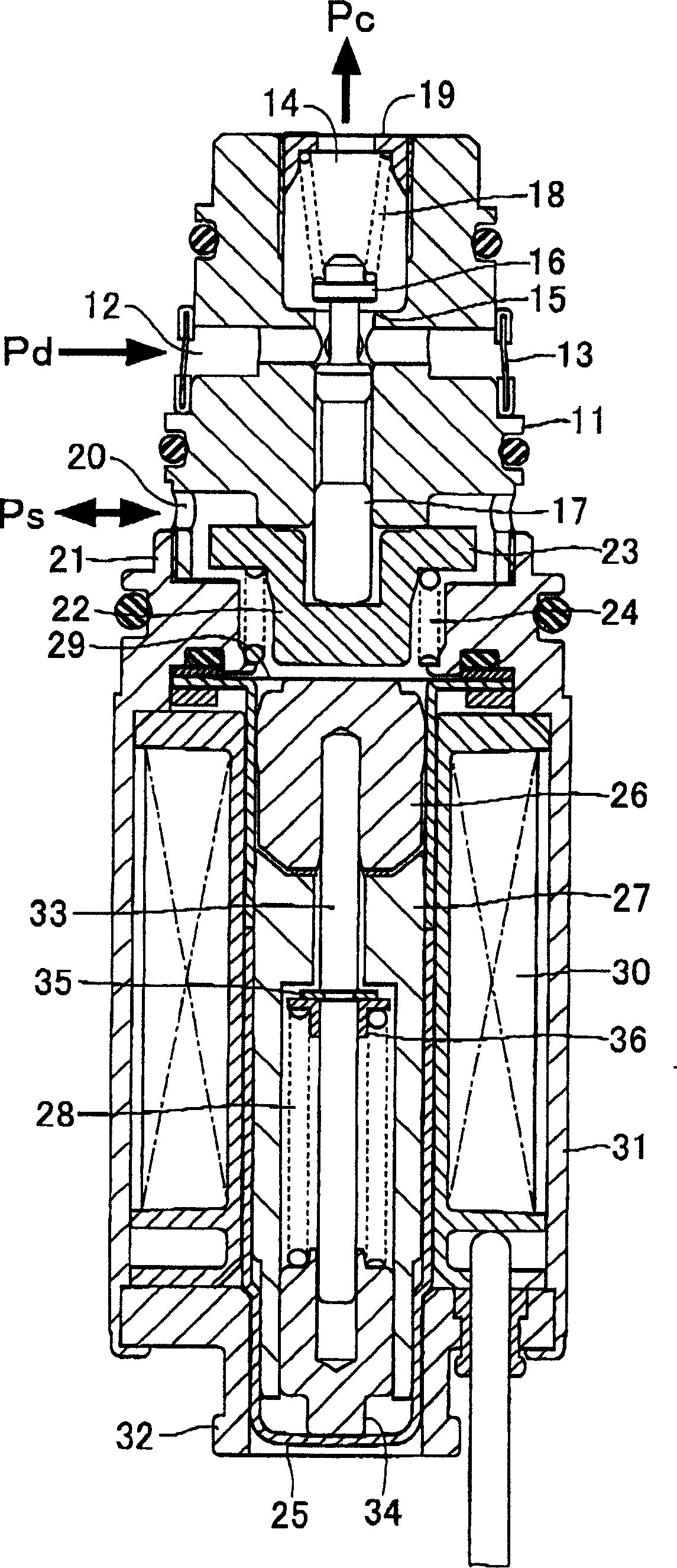

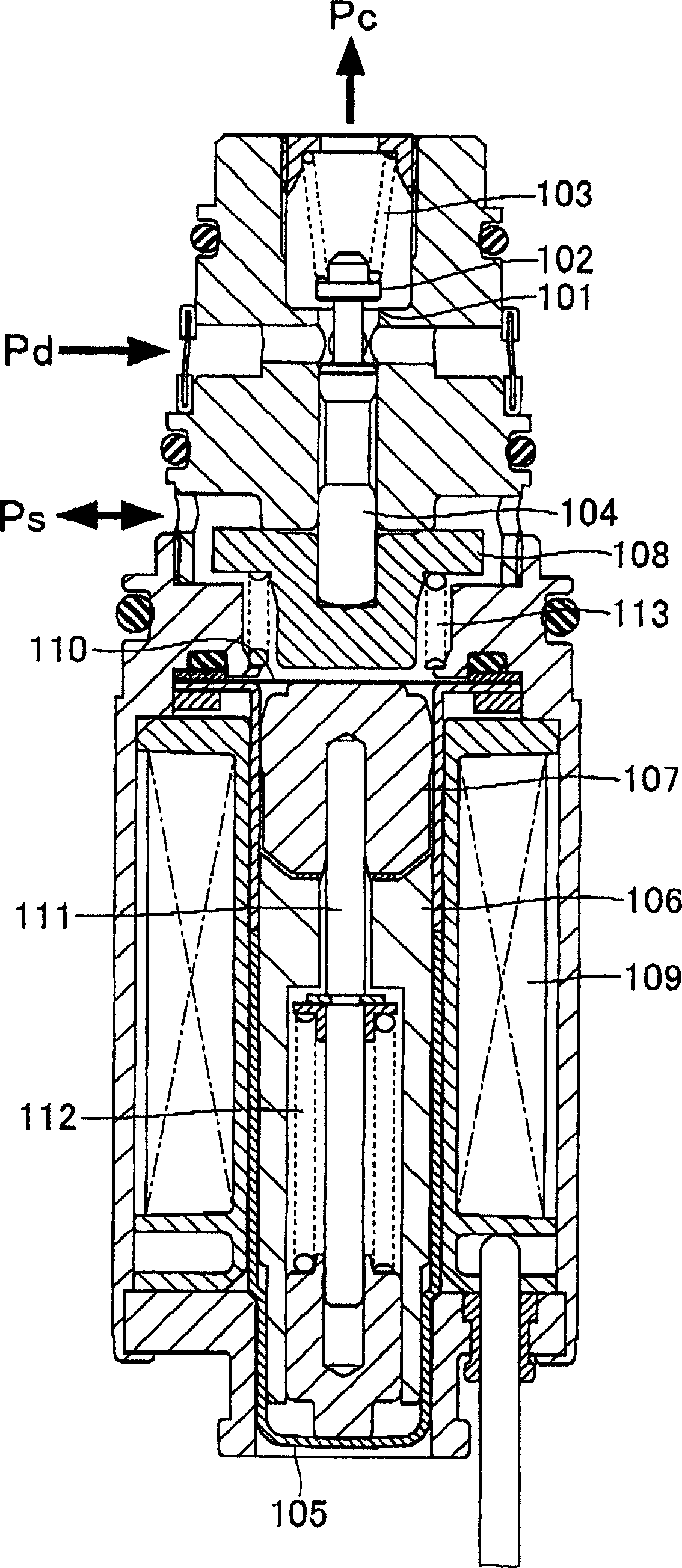

[0024] figure 1 is a central longitudinal sectional view of the structure of a control valve for a variable displacement compressor according to the present invention.

[0025] The control valve is provided with valve sections such as figure 1 shown in the upper part of . The valve portion includes a main body 11 formed with a side opening communicating with the discharge chamber of the variable displacement compressor to form a port 12 for receiving the discharge pressure Pd from the discharge chamber. Port 12 has a filter 13 fixed on its periphery. The port 12 for receiving the discharge pressure Pd communicates with the port 14 opened at the top of the main body 11 through a refrigerant passage formed through the inside of the main body 11 . Port 14 communicates with the crankcase of the variable displacement compressor, thereby delivering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com