Three-way guidance tape typed heat exchanger

A plate heat exchanger, three-channel technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of low refrigeration efficiency, refrigerant overheating, cumbersome assembly process, etc., and achieve simple production and assembly. , Improve the efficiency of use, the effect of less cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

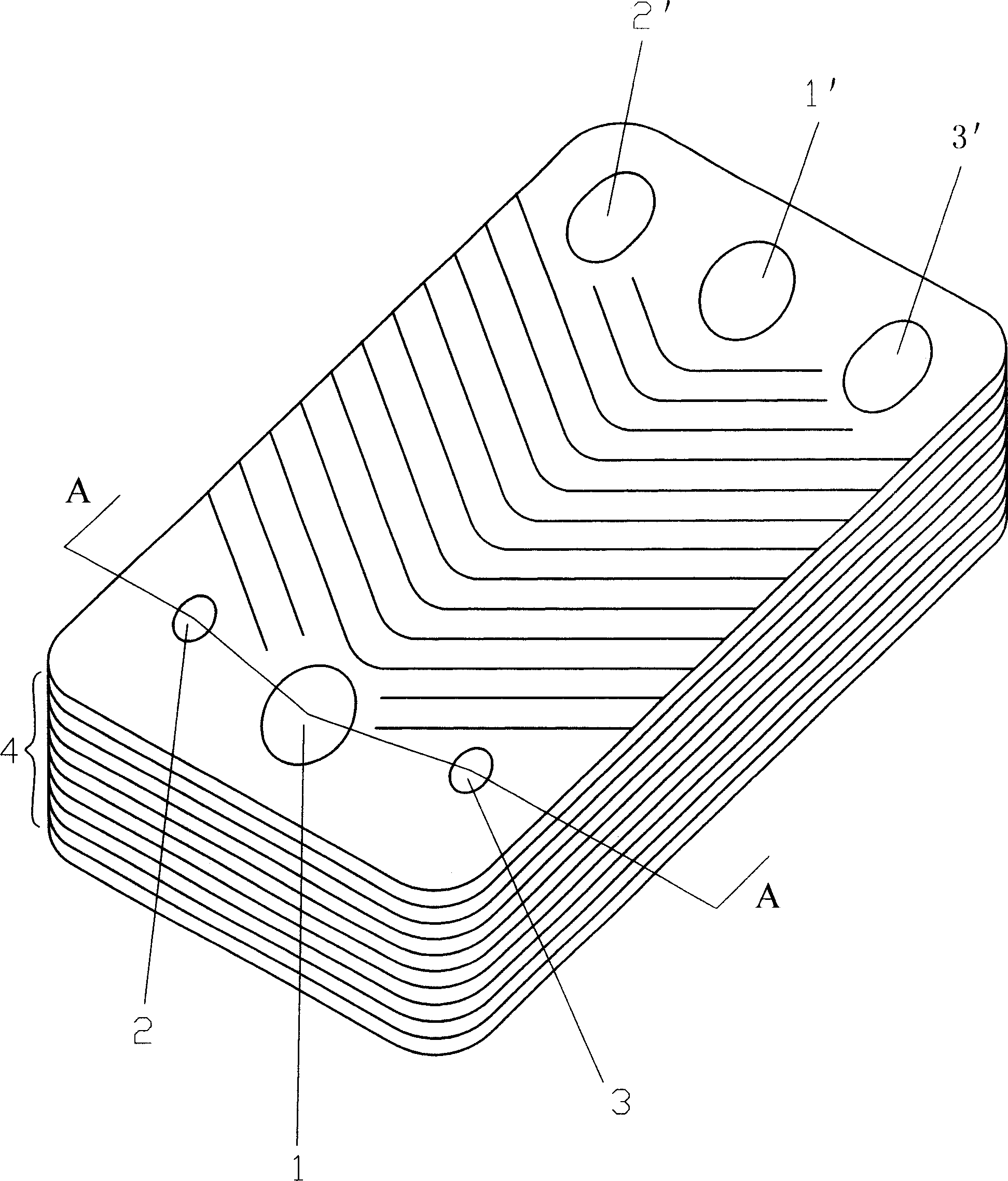

[0020] Example: see figure 1 In the present invention, several heat transfer plates 4 are vacuum brazed into one body, and an upper cover plate and a lower cover plate are arranged on the outside of the heat transfer plate 4, and a first inlet 1, a second two The inlet 2 and the third inlet 3, wherein the first inlet 1 is larger than the second inlet 2 and the third inlet 3, and the other end of the upper cover plate is provided with a first outlet 1', a second outlet 2' and a third outlet 3', .

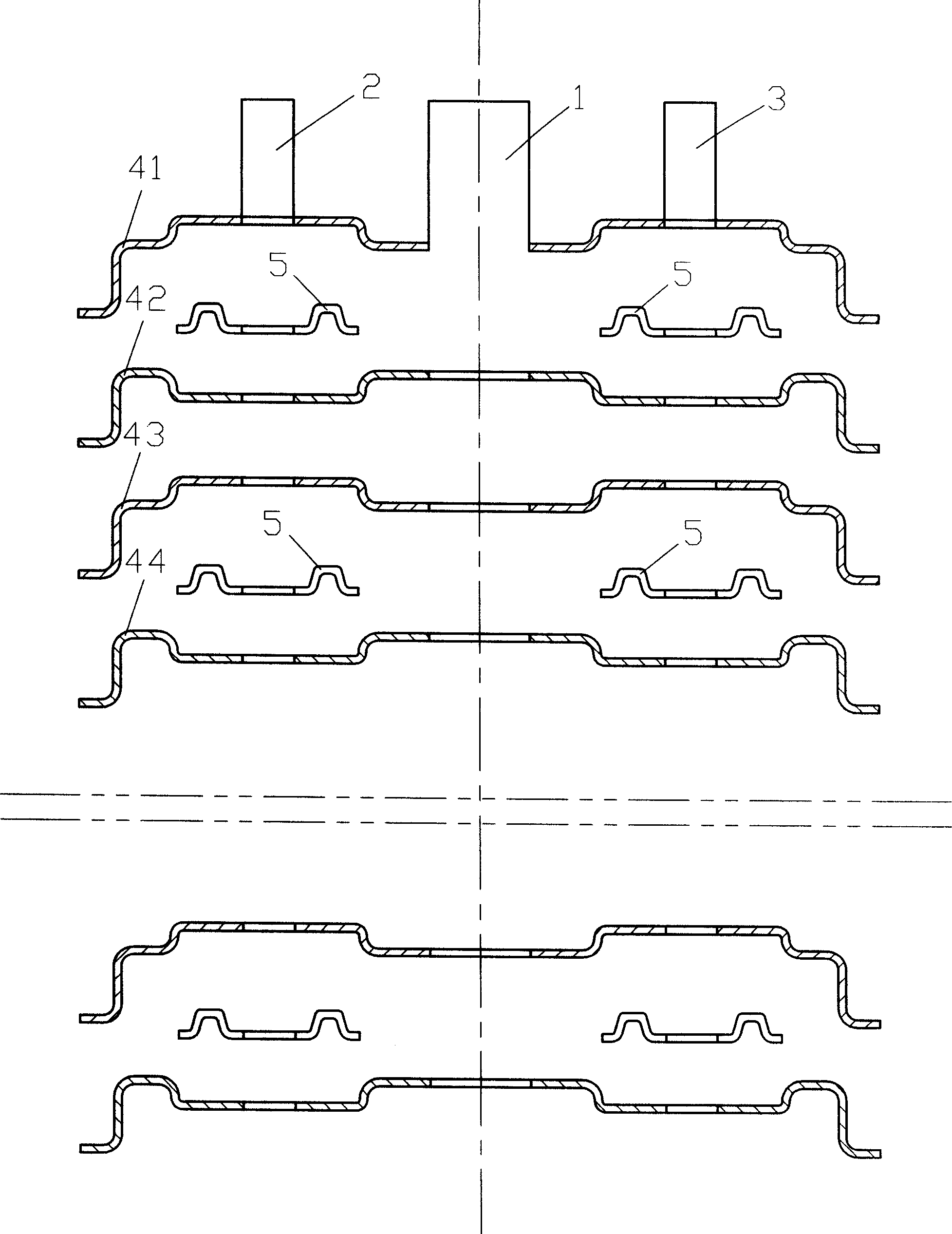

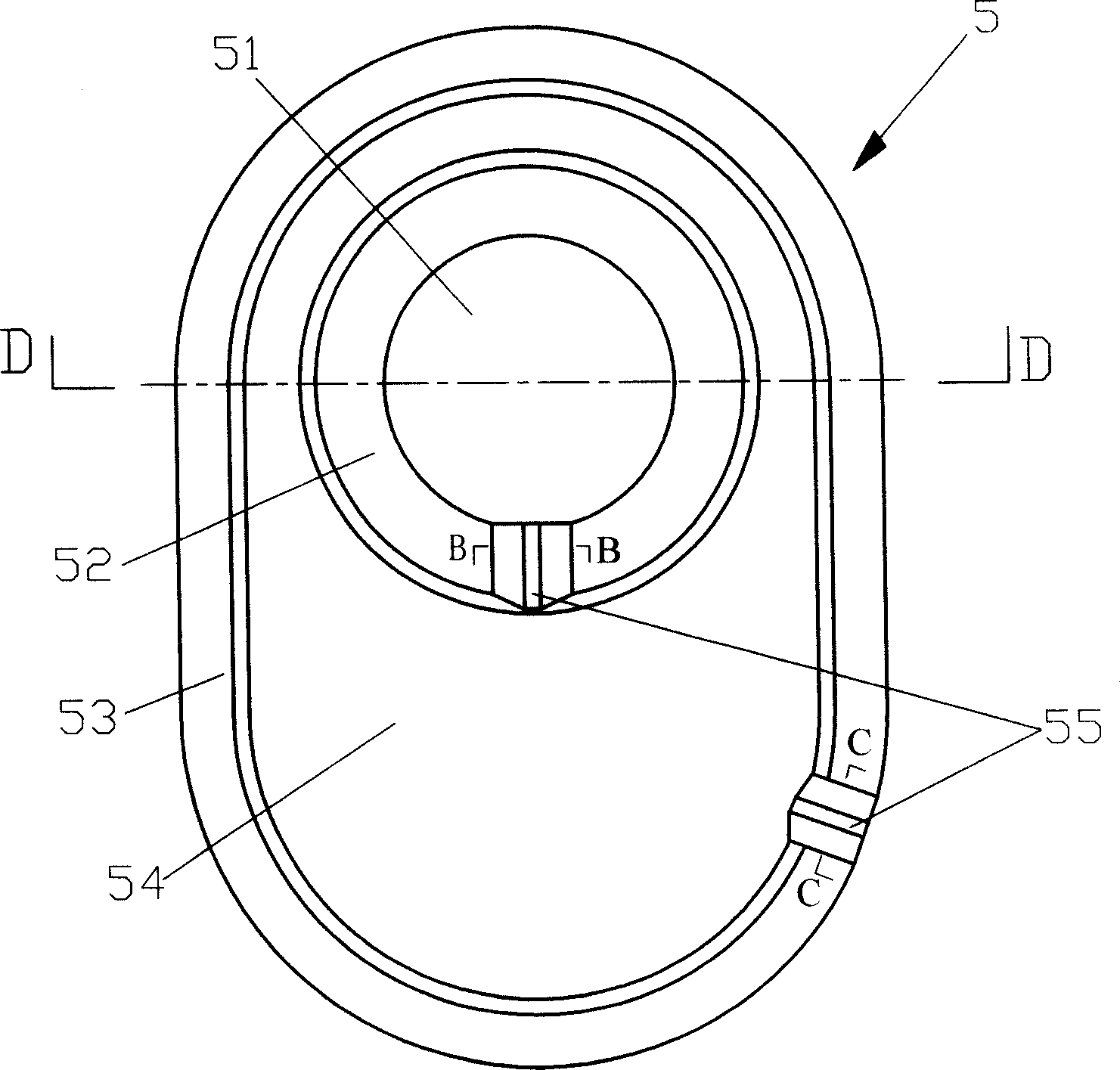

[0021] see figure 2 , the second inlet 2 and the third inlet 3 between the first layer of heat transfer plate 41 and the second layer of heat transfer plate 42 are respectively provided with an equalizer 5, the third layer of heat transfer plate 43 and the fourth layer of heat transfer plate The second inlet 2 and the third inlet 3 between 44 are also respectively provided with an equalizer 5; and so on. The first inlet 1 between the first layer of heat transfer plate 41 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com