Environment-friendly energy-saving normal pressure hot-water boiler

A hot water boiler, environmental protection and energy-saving technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of low thermal efficiency, coal waste, high cost of dust control, etc., to improve thermal efficiency and penetration Larger, higher dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

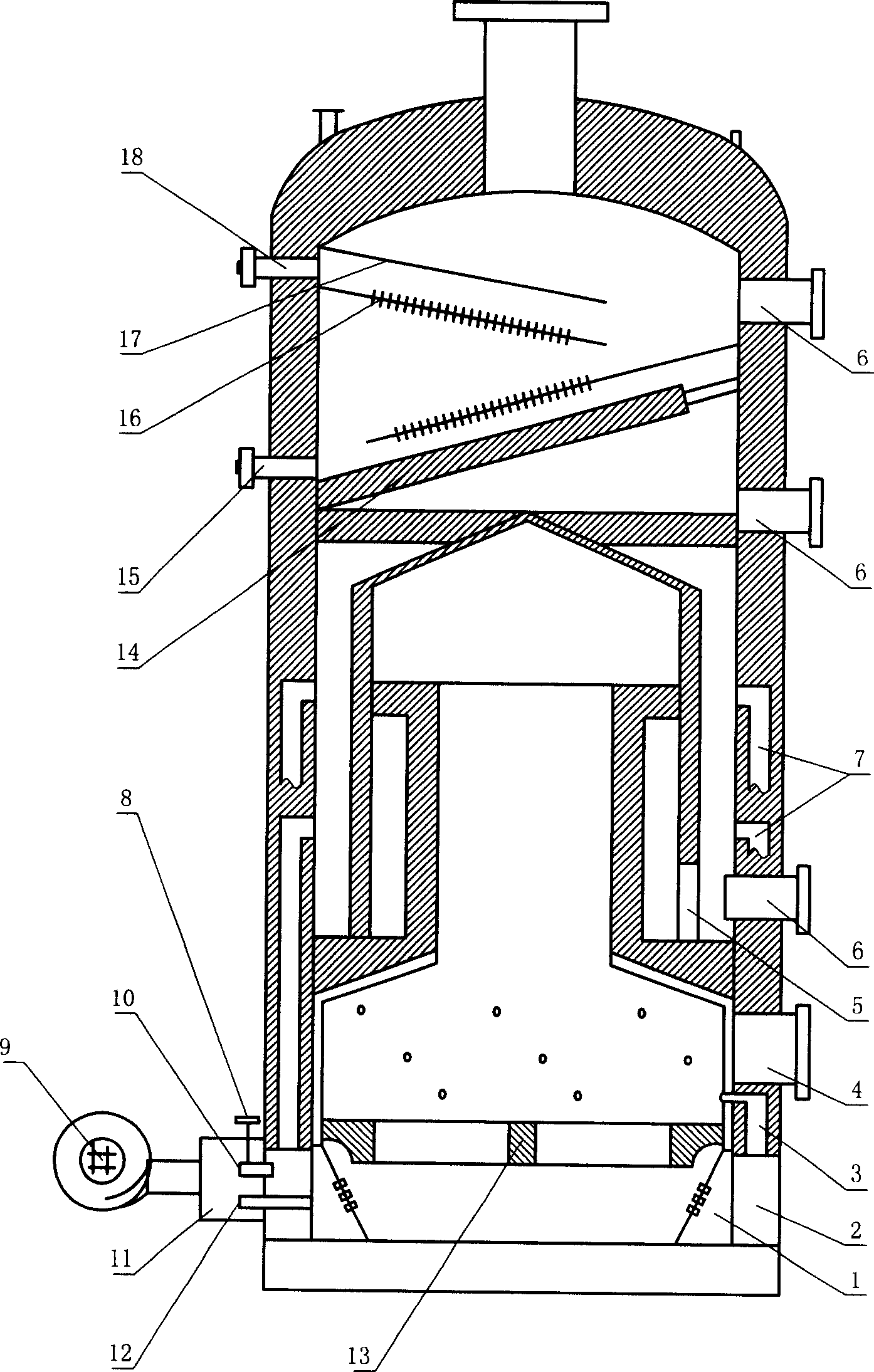

[0020] Such as figure 1 As shown, an environment-friendly and energy-saving normal-pressure hot water boiler includes a furnace shell, a water baffle 17 is arranged obliquely above the inside of the shell, and a circulating water inlet 18 and a circulating water outlet 15 are arranged on the side wall of the shell below the water baffle 17. The bottom of the water retaining plate 17 is also provided with a smoke clearing water board 16, and the smoke clearing water board 16 is provided with a sieve hole, and the smoke clearing water board 16 is provided with an inclined water tank 14, and the inclined water tank 14 is provided with a loop-type multiple The first layer of hot water tank, the outer wall of the hot water tank is equipped with a dust cleaning port 6, the middle layer of the hot water tank wall is equipped with a smoke outlet 5, the lower part of the boiler is the combustion chamber, and the space above the combustion chamber is composed of multiple layers of hot wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com