Three-phase front end processor for internal recycle anaerobic reactor

An anaerobic reactor and processor technology, applied in anaerobic digestion treatment, biological sludge treatment and other directions, can solve the problems of low removal rate, loss, difficult to cultivate granular sludge, etc., and achieve a simple structure and low construction cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

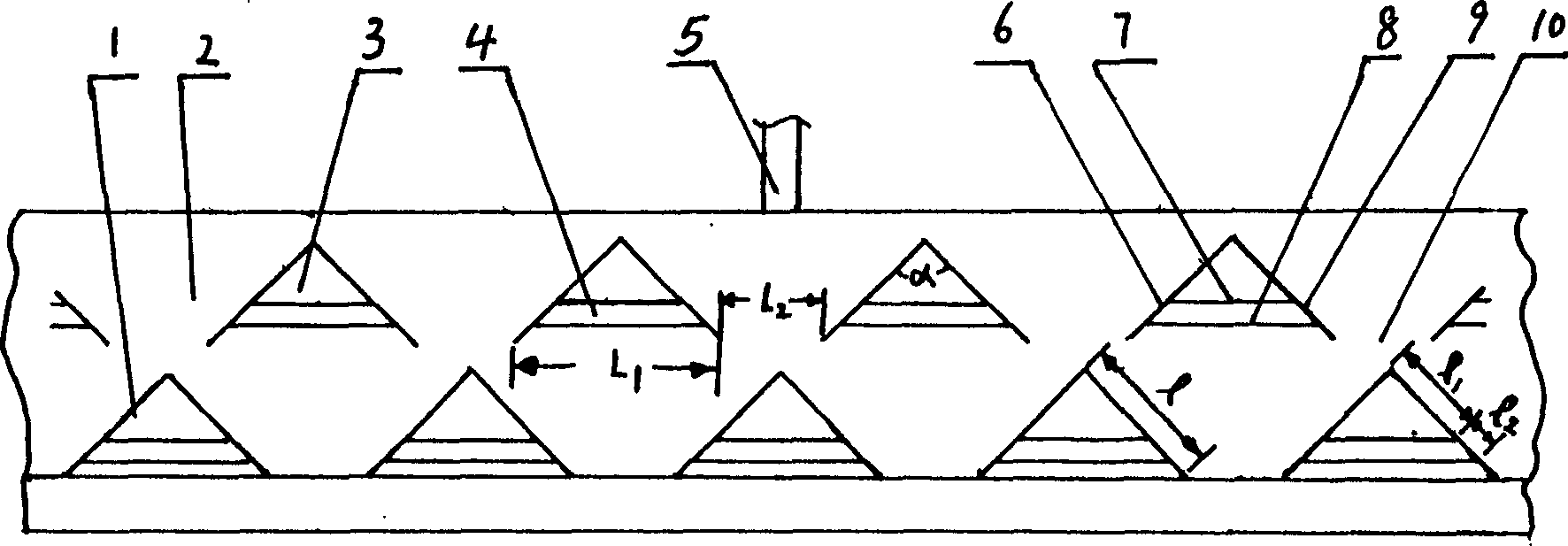

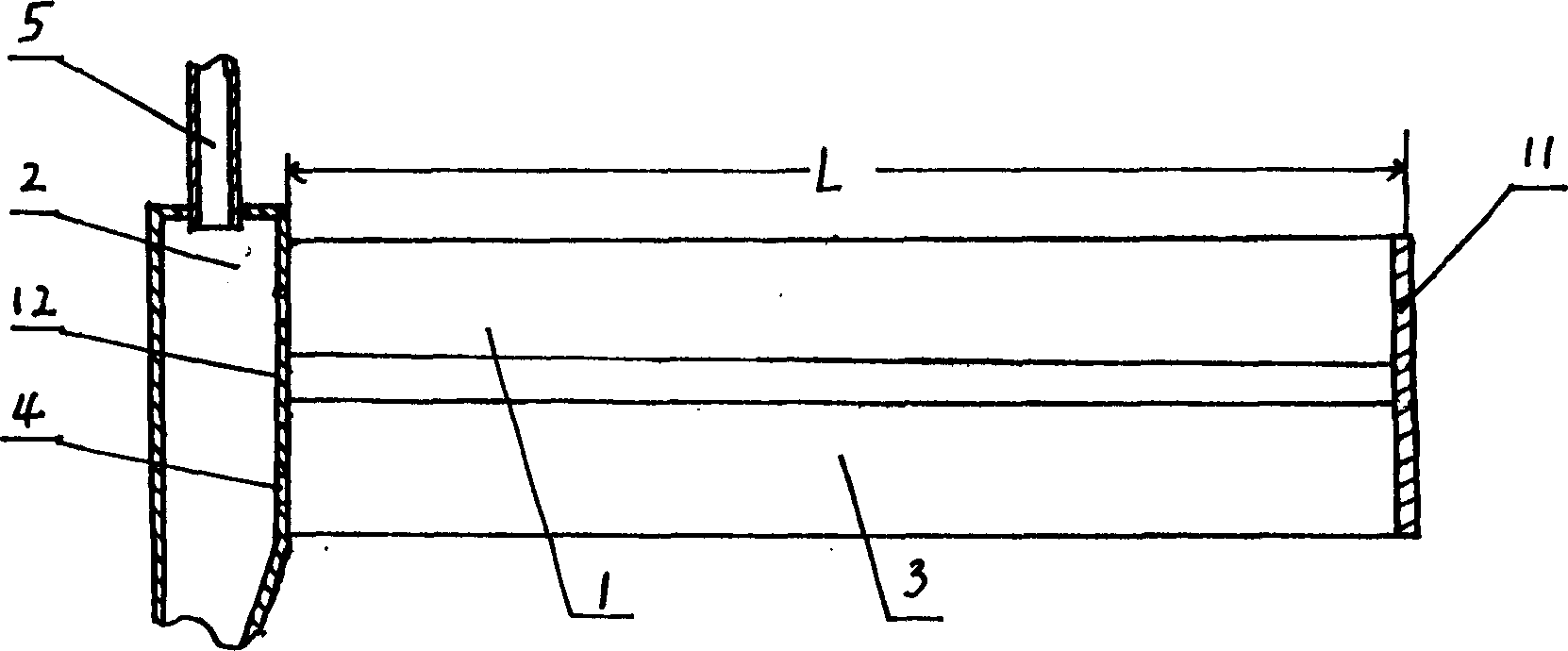

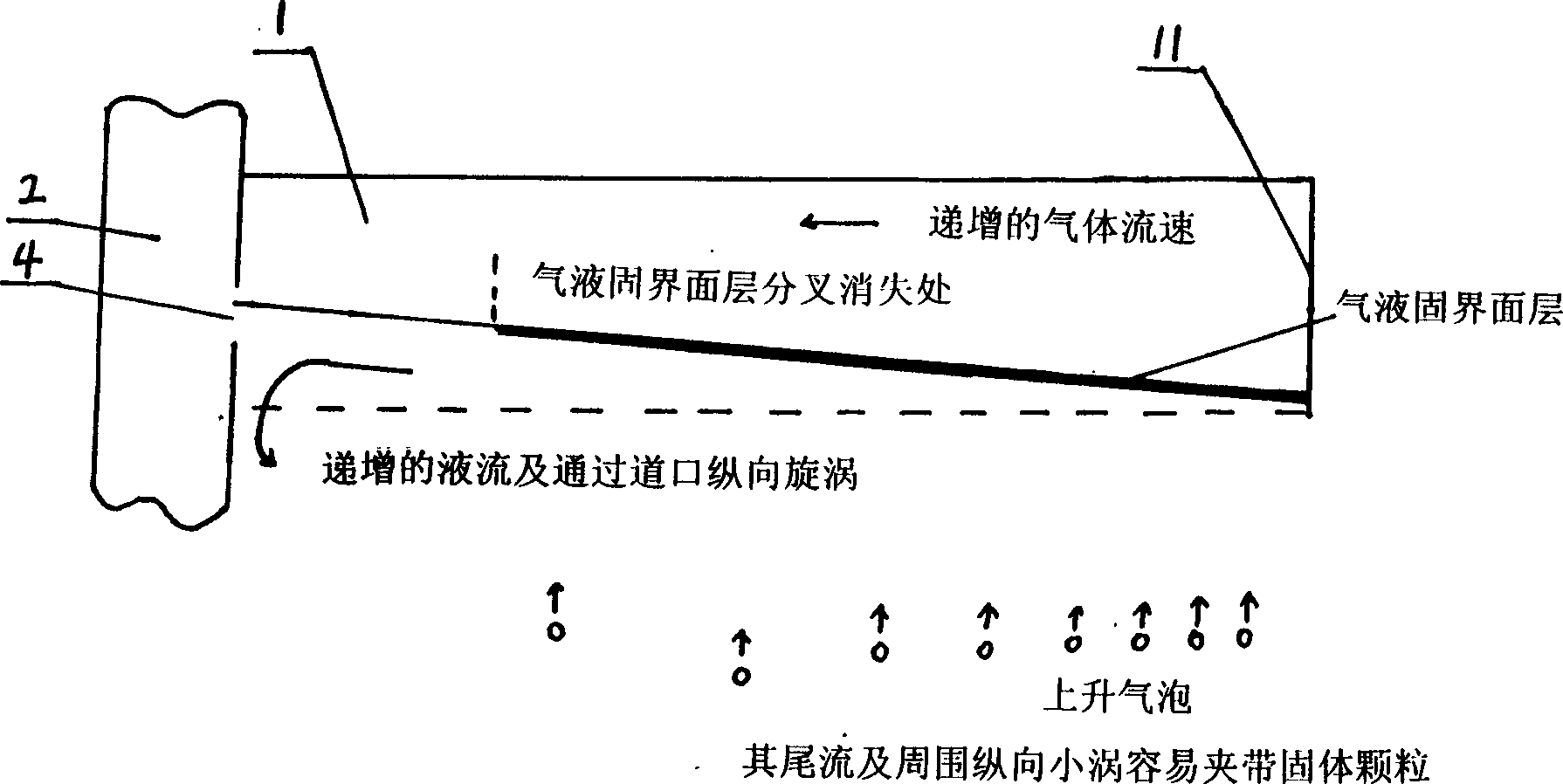

[0026] The three-phase front-end processor of the present invention includes at least two layers of inverted V-shaped horizontal gas collecting tanks 1 in a cross configuration and a "π"-shaped horizontal collecting tank 2 with a riser 5 connected to the top. One end of the gas collecting tank 1 is connected vertically On the side plate 12 of the collecting tank 2, fluid and particle channels 10 are left between the lower ends of the horizontally adjacent gas collecting tanks 1, and the middle and lower part of the gas collecting tank 1 is connected to the channel port 4 of the collecting tank 2 on the side plate 12 The shape is trapezoidal, and a triangular block 11 with a cross-section equal to that of the gas collecting groove 1 is provided at the other end of the gas collecting groove 1; in operation, an air chamber 3 is formed above the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com