Sewing machine

A sewing machine and sewing technology, applied in the field of sewing machines, can solve problems such as difficulty in obtaining strength and complex molding of resin frame, and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The best mode for carrying out the present invention will be described below with reference to the drawings.

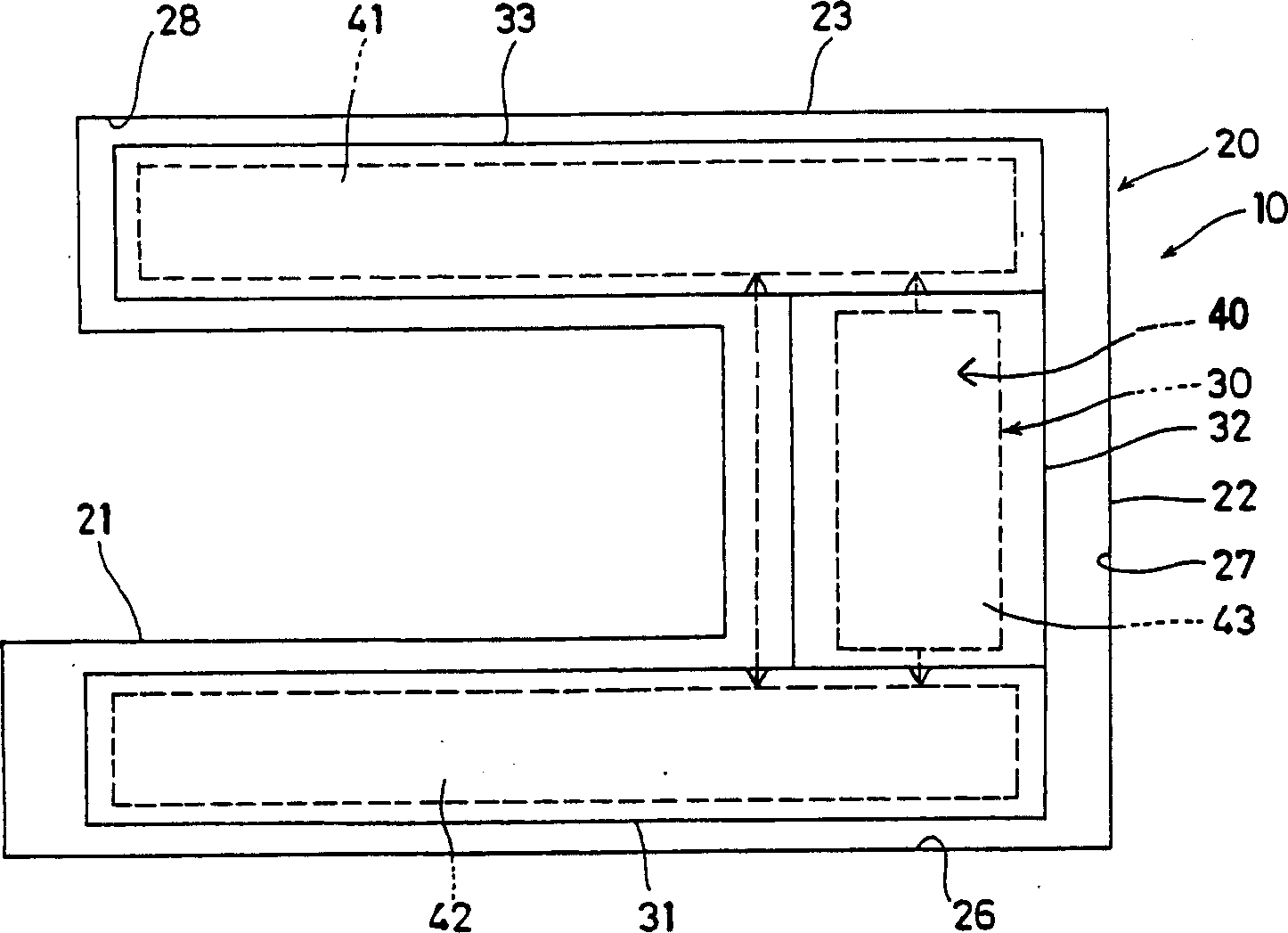

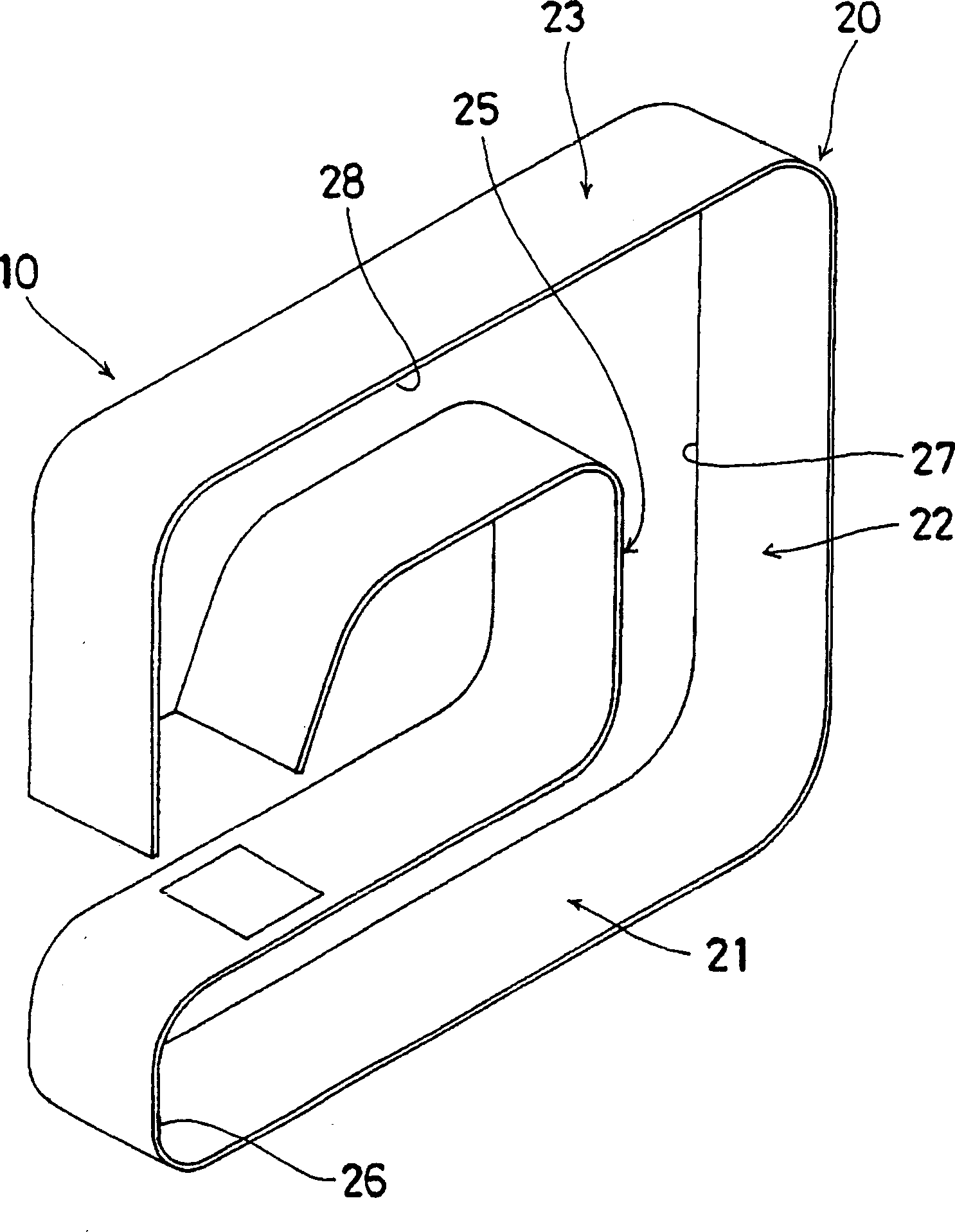

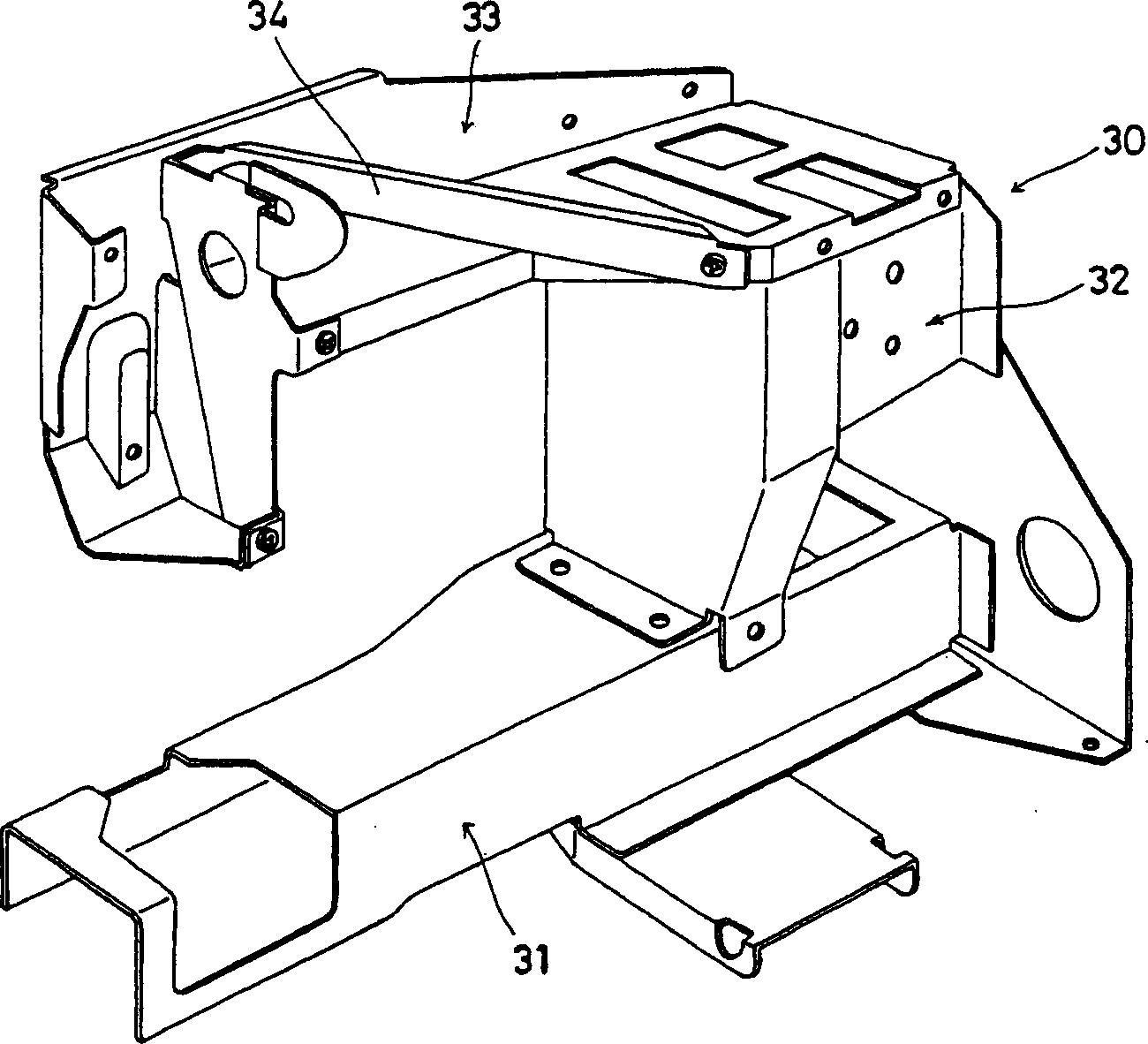

[0027] figure 1 and figure 2 Among them, the sewing machine 10 has a frame 20 made of resin. Resin frame 20 consists of a base portion 21 placed on a console (not shown), a foot column portion 22 erected from one end of the base portion 21, and a base portion 22 extending from the base portion 22 to the top of the base portion 21. The arm portion 23 is integrally formed.

[0028] The internal space 25 of the resin frame 20 is a single space in which the internal space 26 of the base part 21 , the internal space 27 of the leg part 22 , and the internal space 28 of the arm part 23 are connected. figure 1 and figure 2 In the drawing, the internal space 25 of the resin frame 20 is drawn in an open state, and the open surface becomes closed by a cover member (not shown in the figure).

[0029] As will be described later, the internal space 25 of the resin fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com