Damping force adjustable vibration damper

A shock absorber and damping force technology, applied in the field of parts and components, can solve the problems of poor ride comfort and handling stability, longer braking distance, poor anti-slip ability, etc., and achieve satisfactory handling stability and improved driving safety. , the effect of the acceleration and braking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

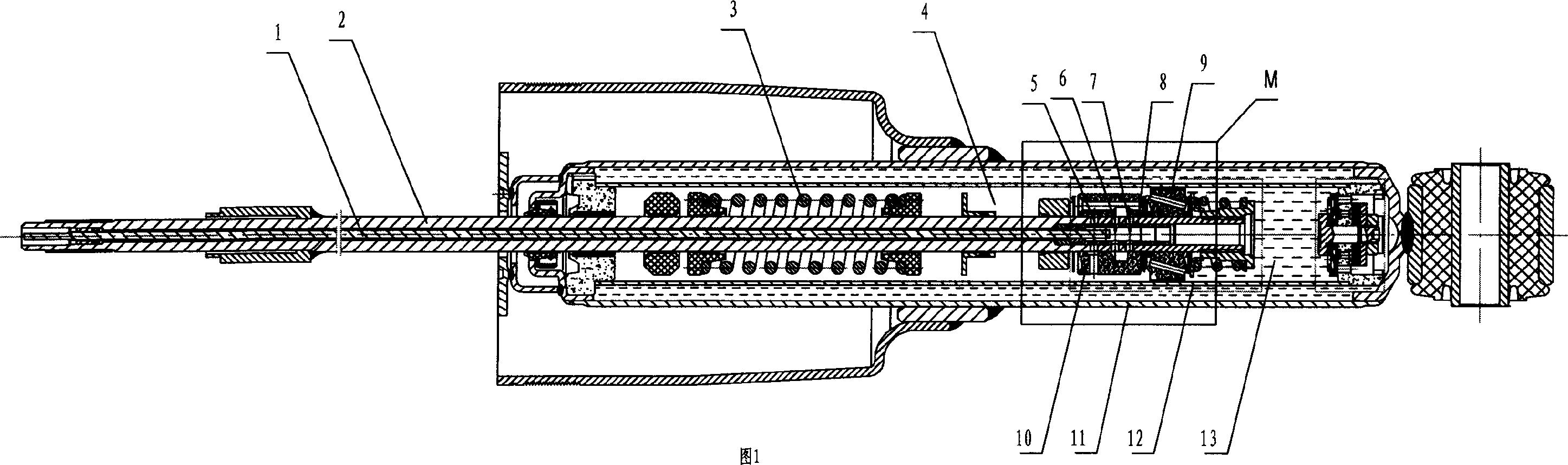

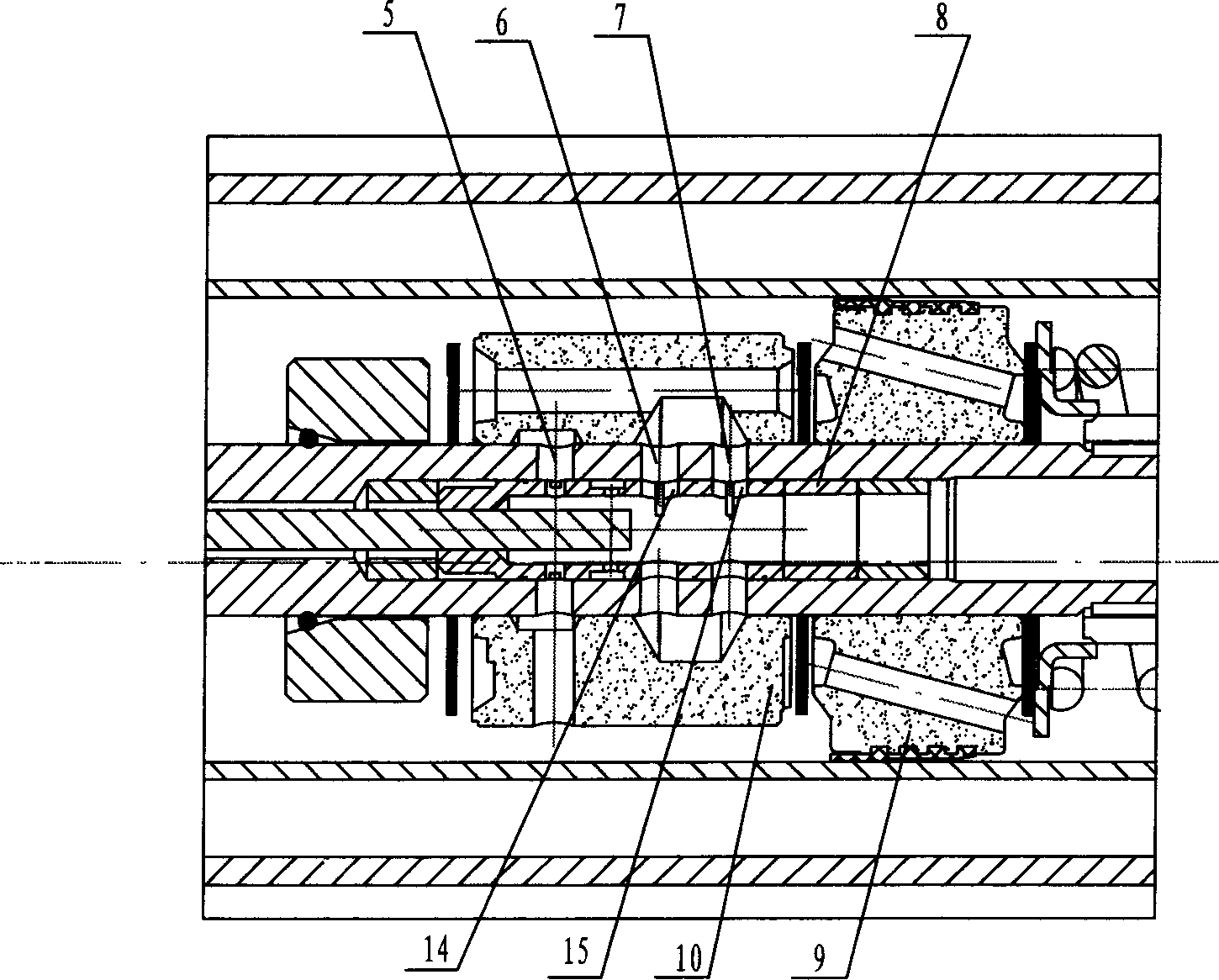

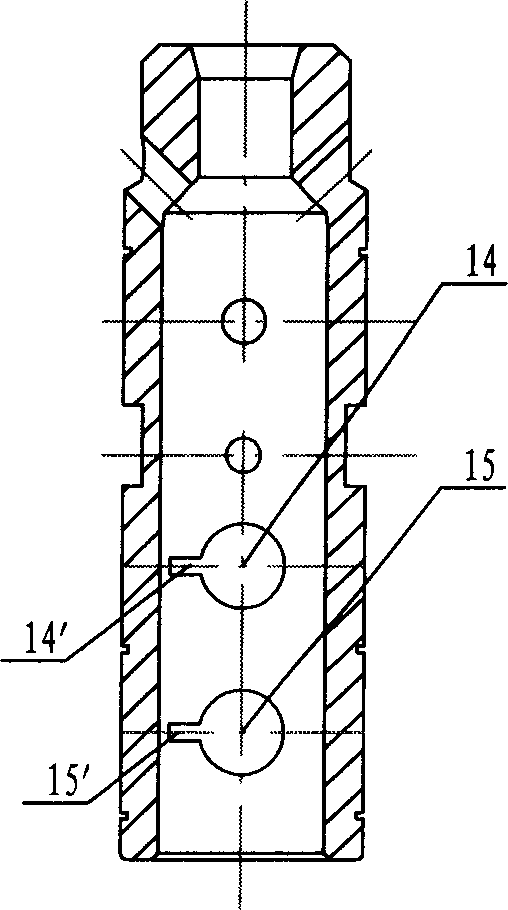

[0009] With reference to the drawings, the shock absorber with adjustable damping force includes a liquid storage cylinder 11, a shock absorber cylinder 12, a buffer spring 3, a valve body 10, a piston 9 and a piston rod 2, and the piston 9 will reduce vibration The shock absorber cylinder 12 is spaced into an upper oil chamber 3 and a lower oil chamber 13, the shock absorber cylinder 12 is placed in the liquid storage cylinder 11, the buffer spring 3 is sleeved on the piston rod 2, and the piston rod 2 passes through Through the valve body 10 and connected with the piston 9, the part of the piston rod 2 passing through the valve body 10 is provided with three oil holes 5, 6, 7, the piston rod 2 is a hollow body, and the piston rod 2 is a hollow body. A regulating rod 1 is arranged in the hollow body, and a valve core 8 is arranged in the hollow body where the piston rod 2 passes through the valve body 10 . The valve core 8 is connected with the regulating rod 1 as a whole. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com