Liquid drop discharge head, liquid drop discharge device, and image forming device

A technology of imaging device and discharge device, applied in the direction of inking device, printing, piezoelectric device/electrostrictive device, etc., which can solve the problems of high cost of printer and high burden of collecting lead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

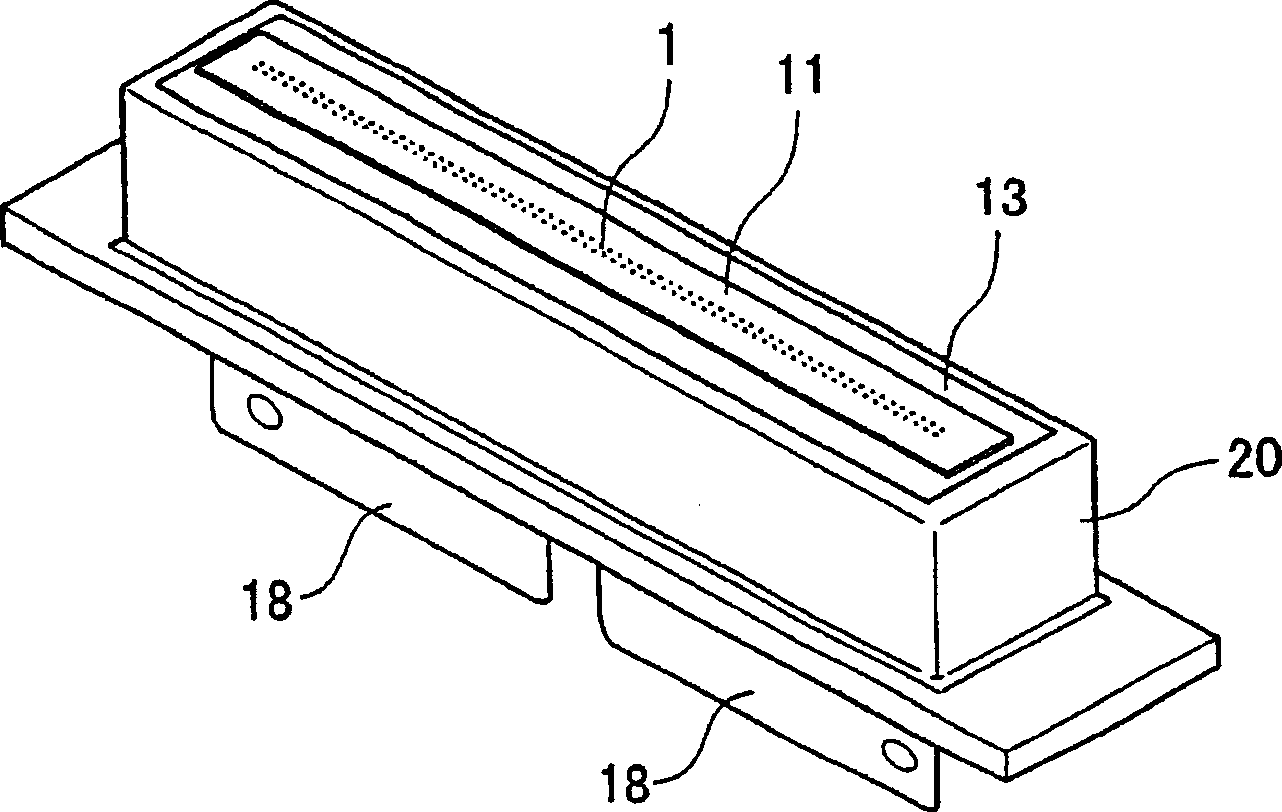

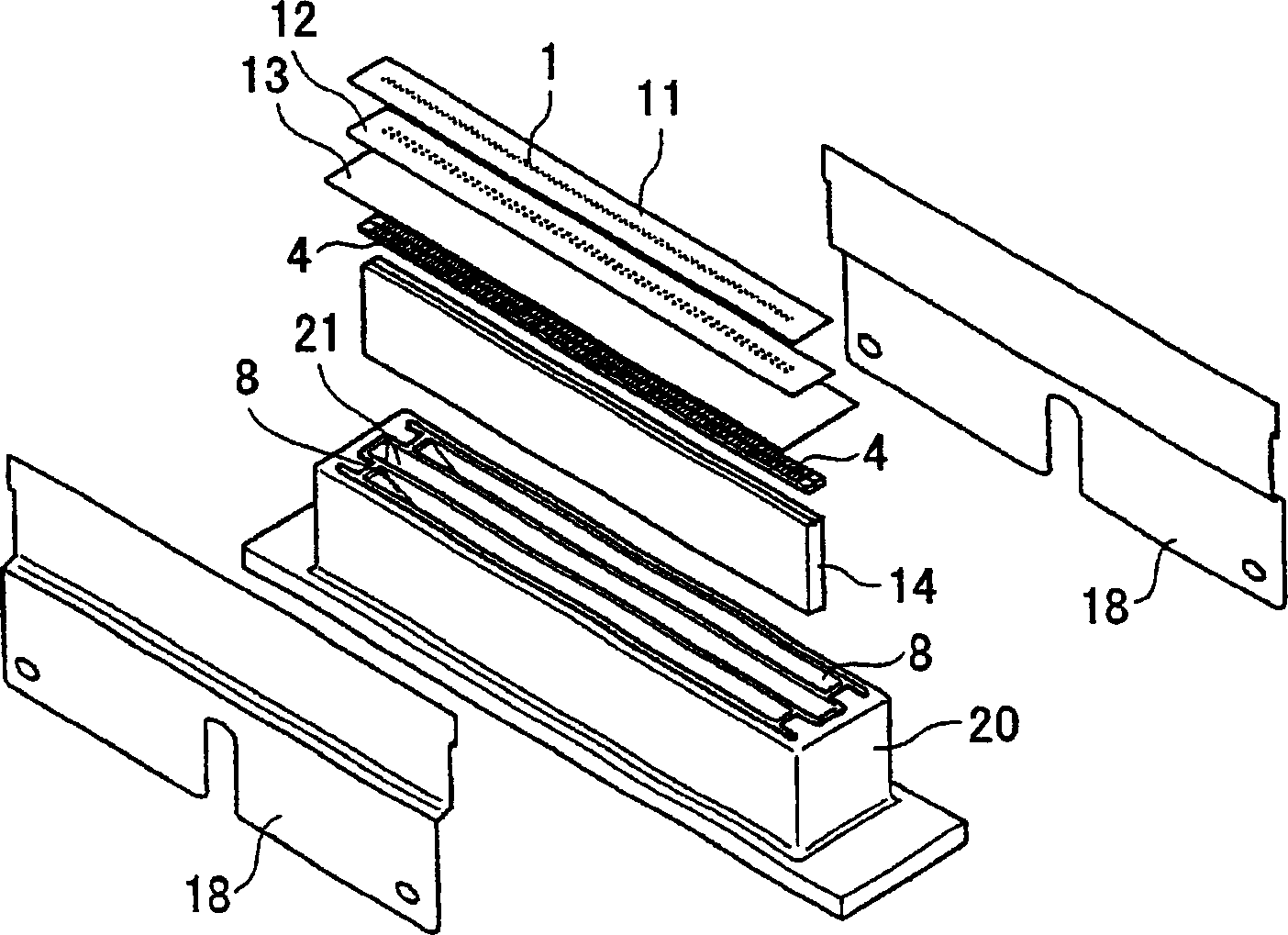

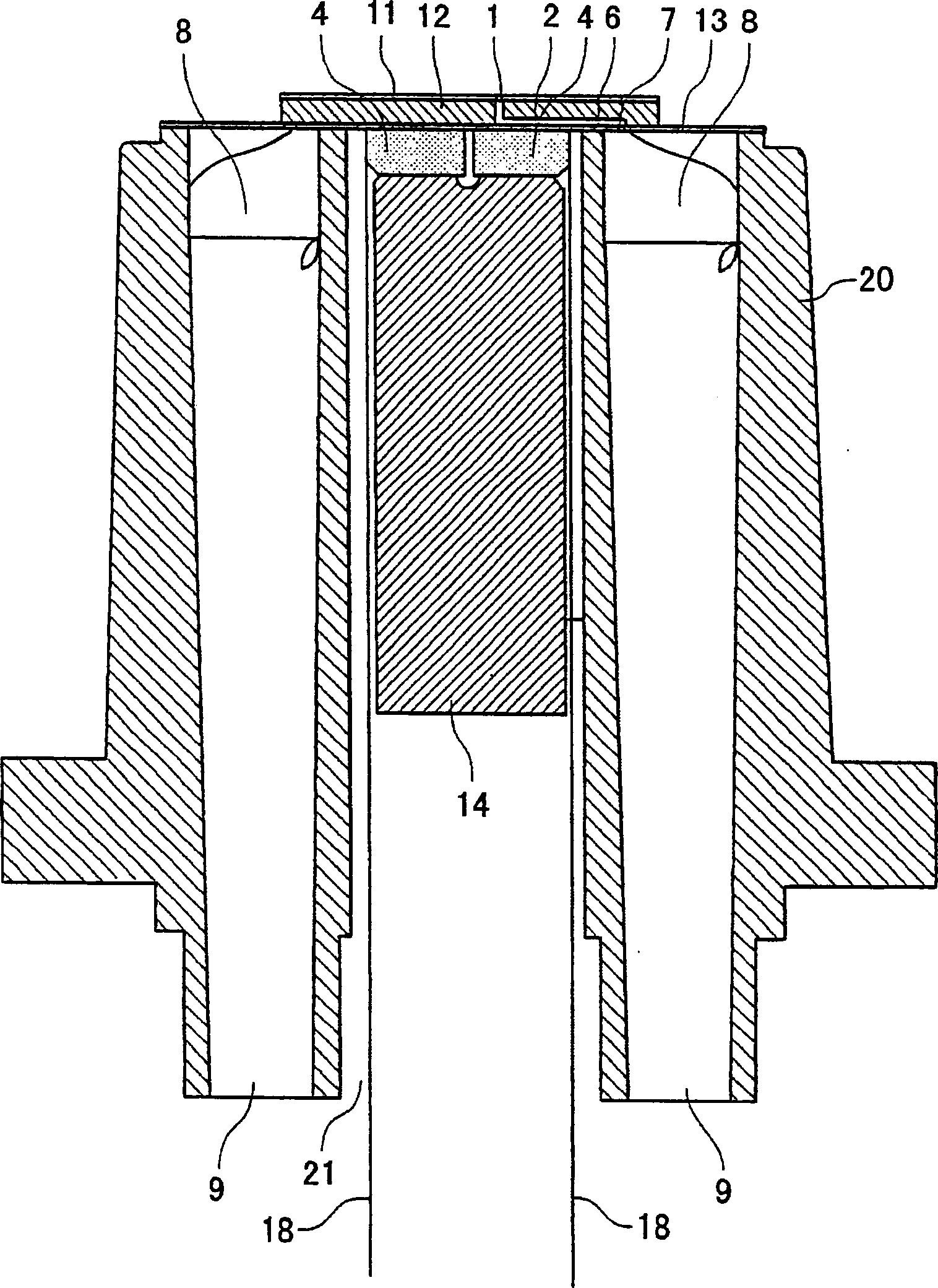

[0030] Reference is now made to the figure 1 - Figure 7 gives a description of the invention and details of the disadvantages of the related art. First, refer to Figure 1-Figure 3 A first embodiment of the droplet discharge head of the present invention will be discussed. figure 1 is a perspective view of the outside of the droplet discharge head. figure 2 is an exploded perspective view of the droplet discharge head. image 3 is a sectional view of the droplet discharge head.

[0031] The liquid drop discharge head has: a nozzle 1 for discharging liquid droplets; a pressure chamber 2 connected to the nozzle 1; a vibrating plate 3 (not shown) forming a side part of the pressure chamber 2; a piezoelectric element 4, the pressure chamber 2 The electrical element 4 can serve as an actuator device, such as a pressure generating device or a drive device that compresses the liquid in the pressure chamber 2 via the vibrating plate 3 . The droplet discharge head also has a comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com