Cavity filter with adjustable capacitive coupling structure

A cavity filter, capacitive coupling technology, applied in waveguide-type devices, circuits, resonators, etc., can solve the problems of small adjustment range, multiple opening and adjustment, time-consuming and labor-intensive, etc., to avoid wear and tear, reduce debugging difficulty, The effect of improving insertion loss performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

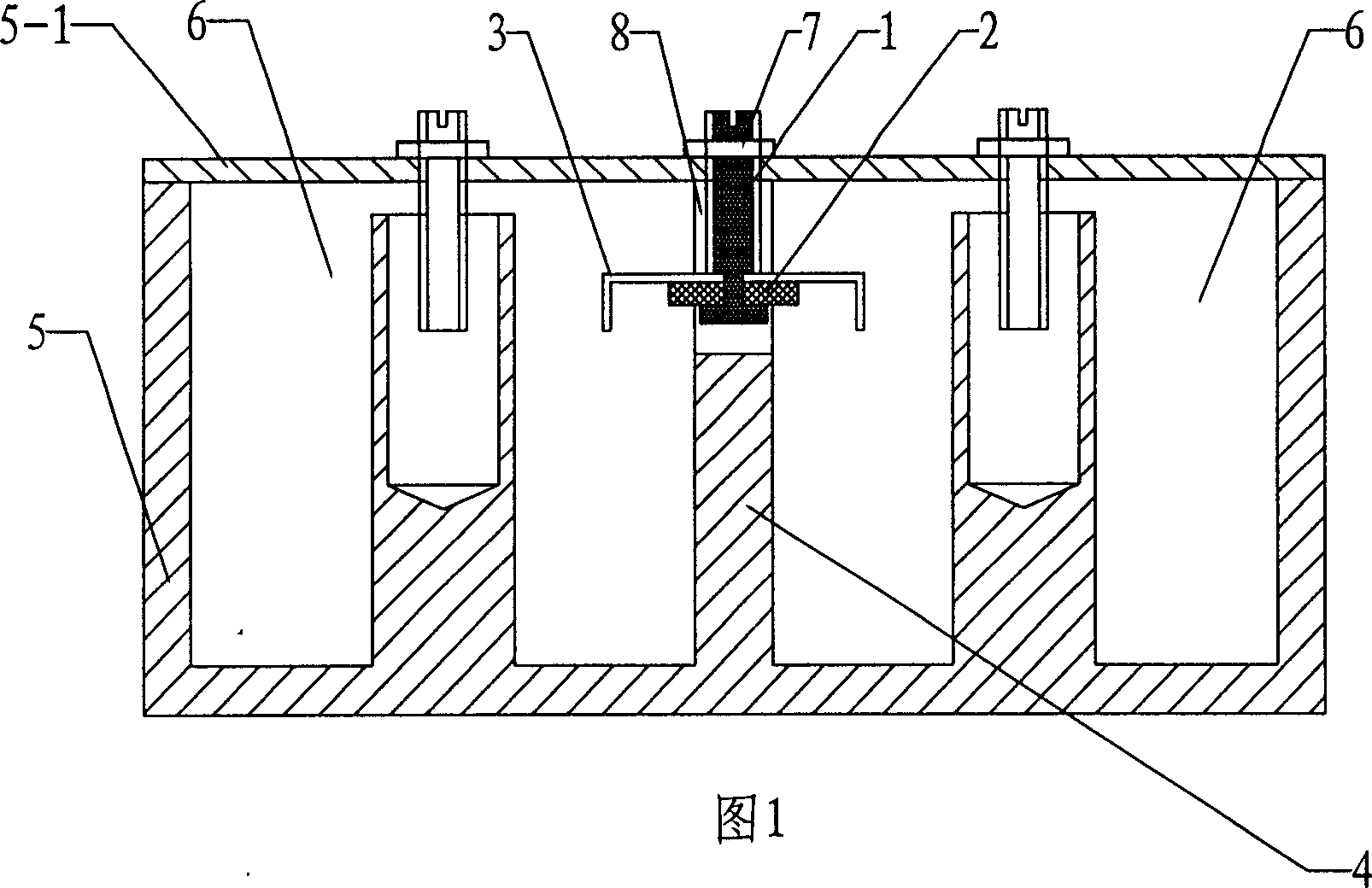

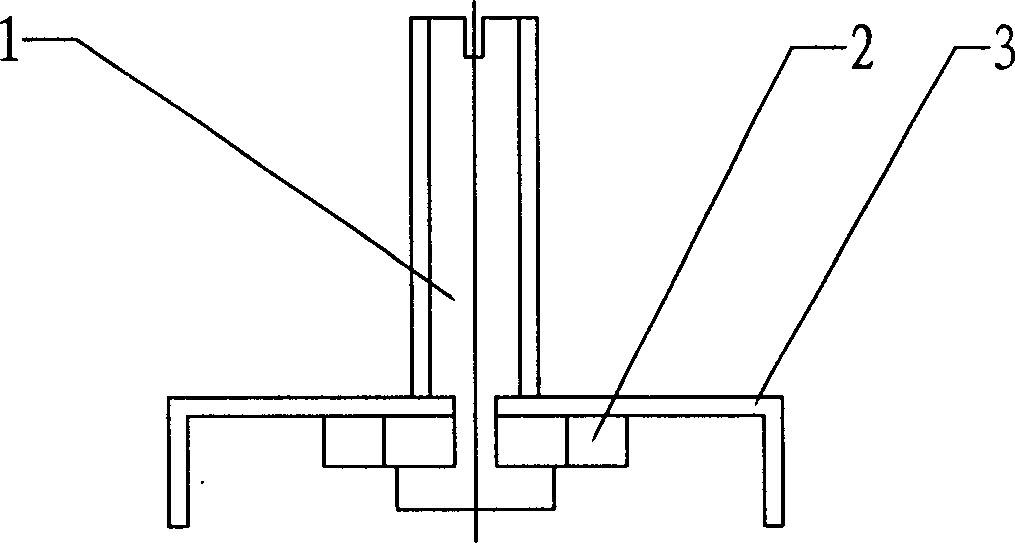

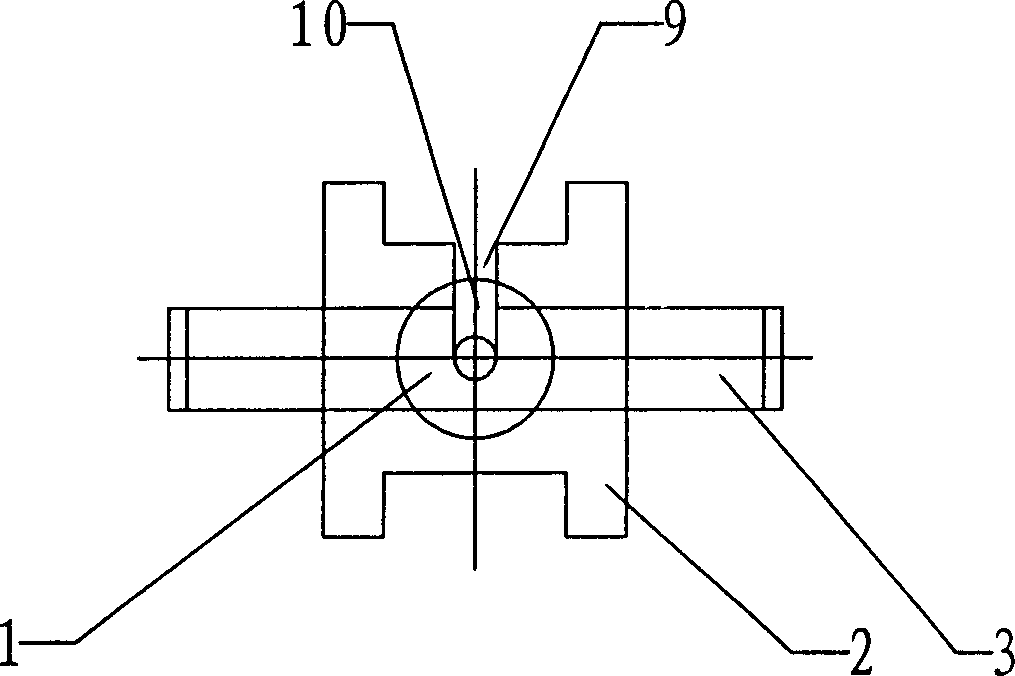

[0022] As shown in the figure, this cavity filter with an adjustable capacitive coupling structure includes a housing 5, and a resonant cavity 6 is opened in the housing 5, and between two non-adjacent coaxial resonant cavities 6 that require capacitive coupling A slot 8 is opened on the partition wall 4 between them, and an adjustable capacitive coupling assembly is arranged in the slot 8, and the adjustable capacitive coupling assembly includes a dielectric screw 1 and a metal sheet 3; the dielectric screw 1 is made of a dielectric material, There is a screw pattern on the upper end, and a thinner cylinder is connected between the bottom and the upper end screw pattern. The upper end of the medium screw 1 is fixed on the cover plate 5-1 through the screw female gasket assembly 7, the lower end of which is located in the slot 8, the metal sheet 3 is fixed on the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com