A broadband non-contact circular waveguide rotary joint and its design method

A rotary joint, non-contact technology, applied in the microwave field, can solve the problems of wear and rotation of circular waveguide rotary joints, unable to meet the requirements of frequency changes, narrow working bandwidth, etc., to achieve wide working bandwidth, good standing wave and insertion loss performance, stable the effect of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments disclosed in the present invention will be further described in detail below in conjunction with the accompanying drawings.

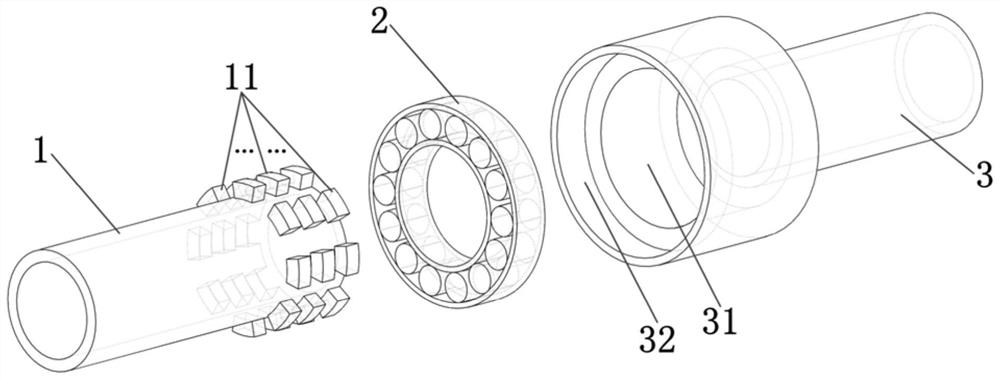

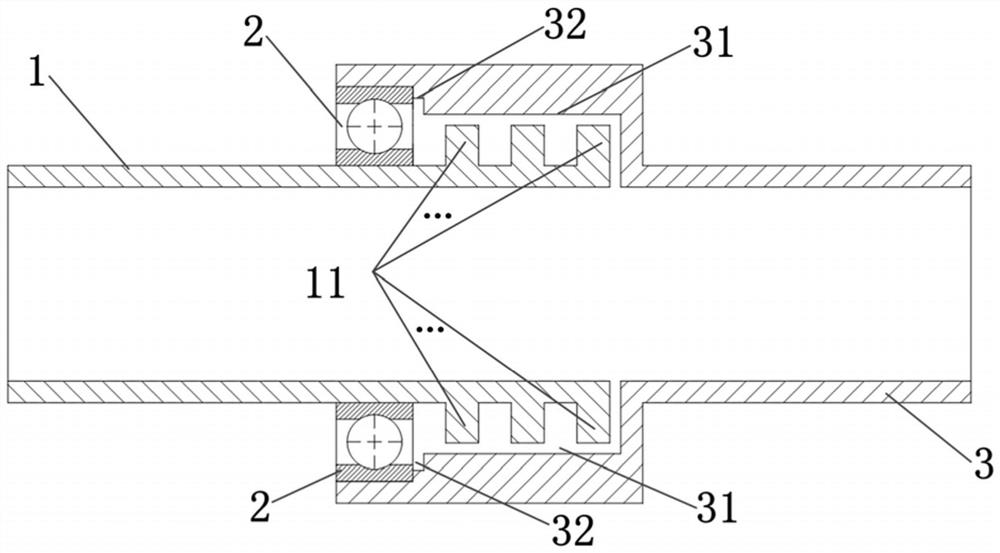

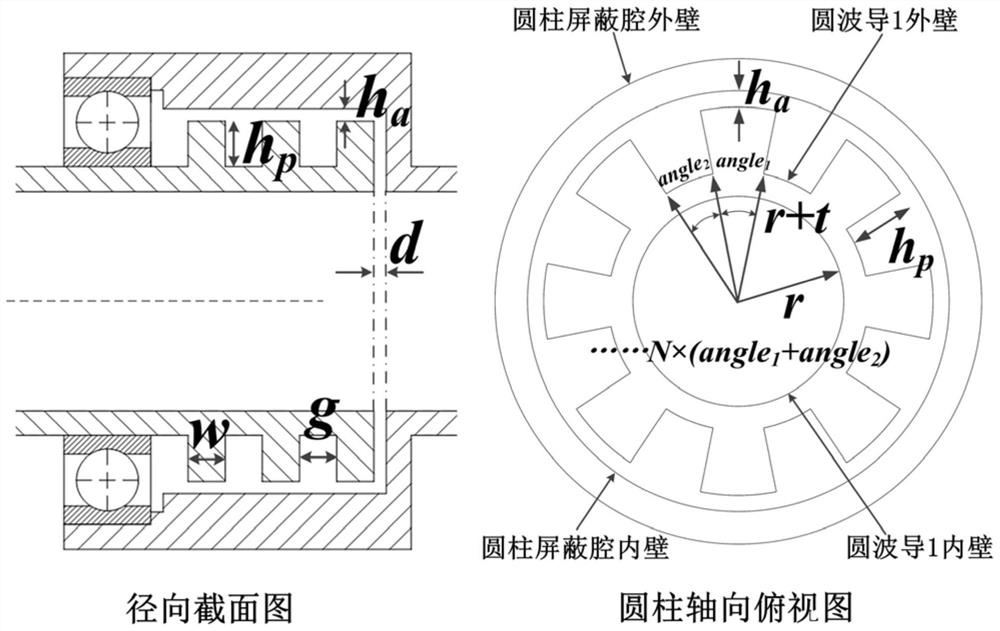

[0062] One of the core ideas of the present invention is to propose a broadband non-contact circular waveguide rotary joint, in which a number of arc-shaped metal convex bodies with equal radius are regularly arranged on the outer wall of the first circular waveguide to form a metal convex body array structure , set the corresponding shielding cavity structure at the end of the second circular waveguide, and under the premise of ensuring that the central axes of the two waveguides coincide, insert the metal convex body array part of the first circular waveguide into the shielding cavity of the second circular waveguide, and the metal convex body array The surface is not in contact with the inner wall of the shielding cavity, and a rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com