Method for mounting rotor blades and rotor blade for a wind turbine

一种转子叶片、转子的技术,应用在安装转子叶片及风轮机的转子叶片领域,能够解决起重机变大等问题,达到简单控制和影响的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

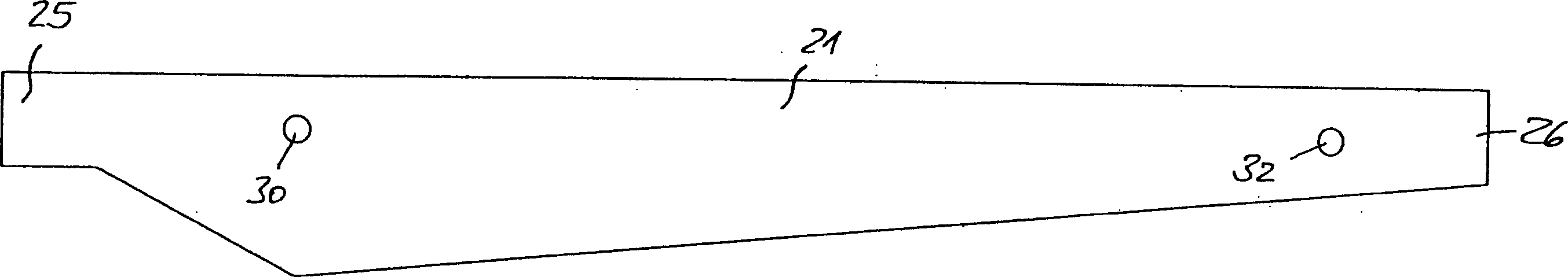

[0031] figure 1 The plan view in is a simplified view of the rotor blade 21 . The rotor blade 21 has two through holes 30 , 32 in the longitudinal direction between the rotor blade root 25 and the rotor blade tip 26 . The through-hole 32 is arranged in the region of the rotor blade tip 26 , while the through-hole 30 is arranged in the region close to the rotor blade root. In this case, these positions are determined in such a way that a safe and reliable handling of the rotor blade must be ensured when the rotor blade is mounted on the rotor hub of the wind power plant. When determining the positions of the holes 30 , 32 , the connection means with respect to the load-bearing structure of the rotor blade 21 are also taken into account.

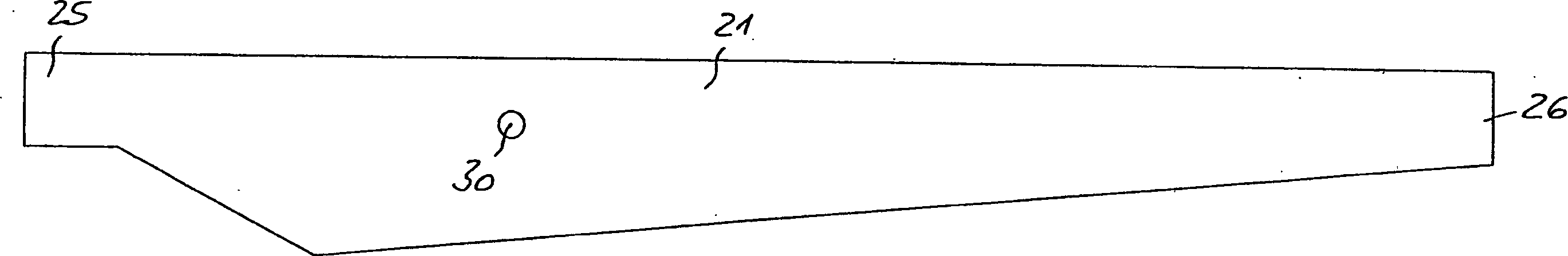

[0032] figure 2 A further embodiment of the rotor blade 21 is shown, which has only one through-opening 30 . This single through-hole 30 is suitably arranged at the center of gravity of the rotor blade so that the blade can be safely mani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com