External broken tiles brake

A technology of brakes and tiles, which is applied in the direction of brake types, drum brakes, brake actuators, etc., can solve problems such as increase, and achieve the effects of volume reduction, power saving, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

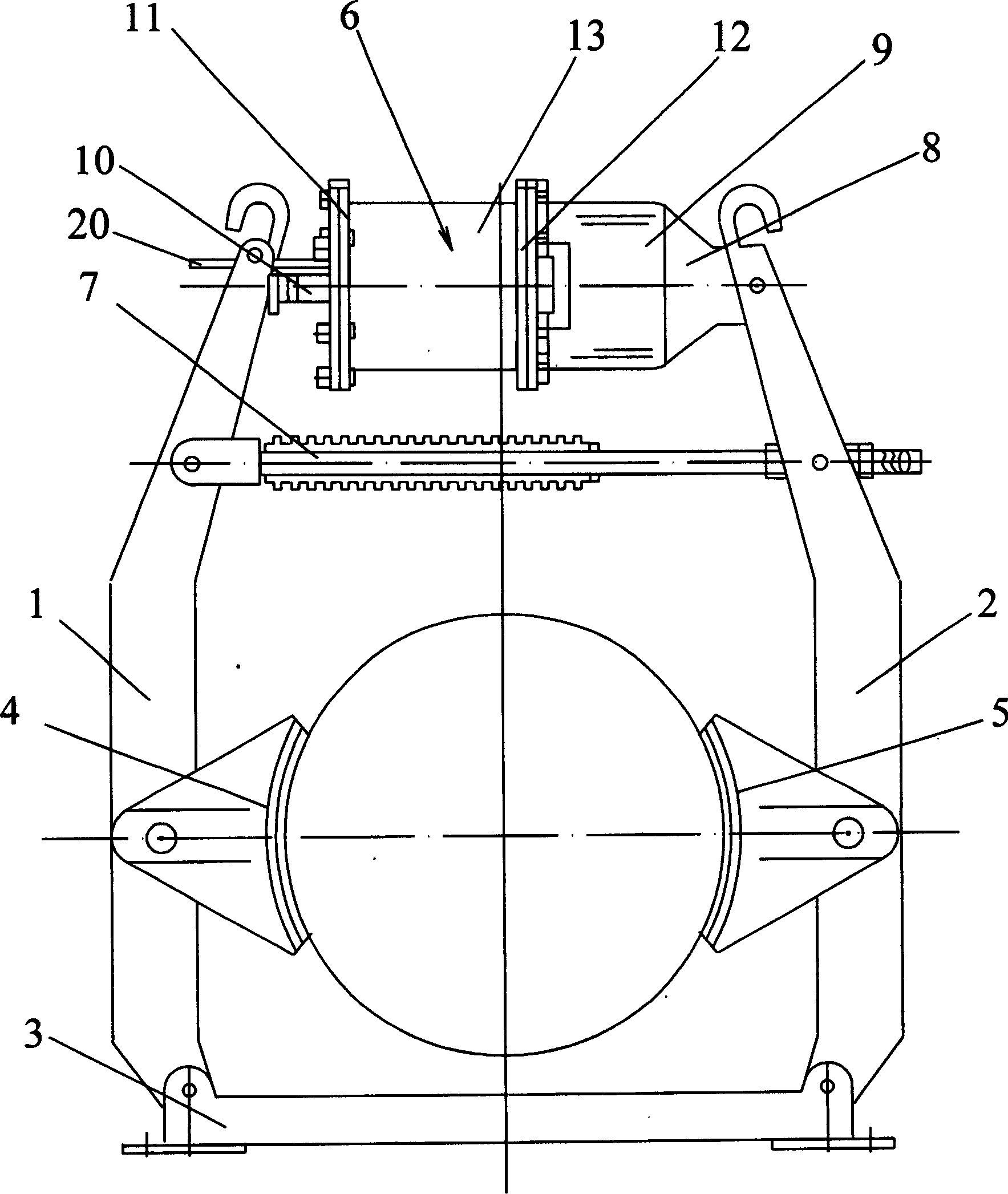

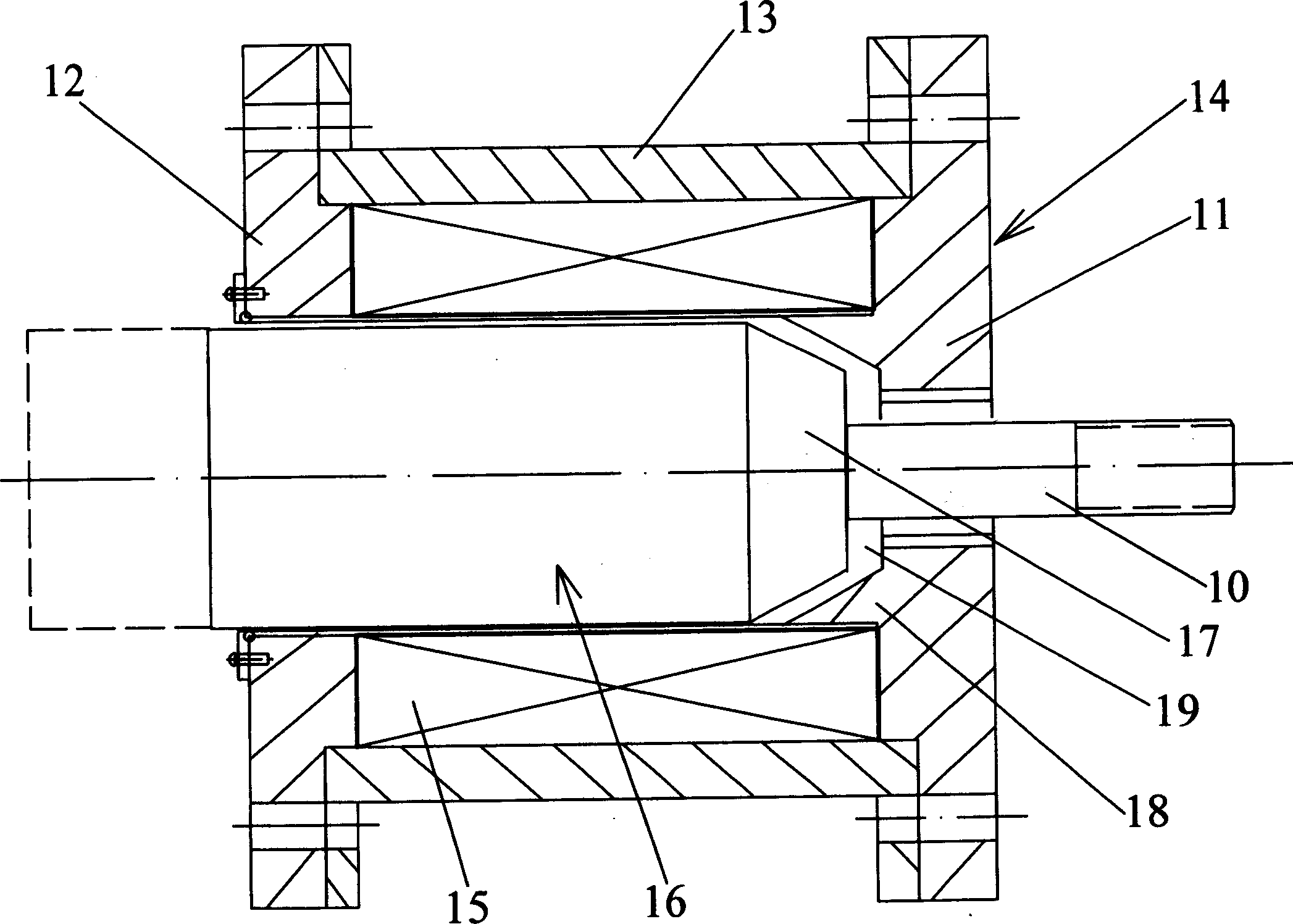

[0017] The outer block brake includes a left brake arm 1, a right brake arm 2, a base 3, a left brake shoe 4, a right brake shoe 5, an electromagnet 6, a brake spring 7 and a rectifier controller 9. The lower ends of the left brake arm 1 and the right brake arm 2 are hinged on the base 3, the two ends of the brake spring 7 are hinged on the left brake arm 1 and the right brake arm 2, the left brake shoe 4 and the right brake The tiles 5 are respectively installed on the left brake arm 1 and the right brake arm 2. The key point of the structure is that the electromagnet 6 is a mid-stroke electromagnet. The electromagnet 6 is arranged above the brake spring 7 and is located on the left brake arm 1. , between the right brake arm 2. The rear end of the electromagnet 6 is fixedly connected with a push-pull connecting plate 8 by bolts. The rectifier controller 9 is fixedly installed on the push-pull connecting plate 8, and the push-pull connecting plate 8 is hinged with the right b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com