Method of controlling electronic cam and servo motor control system

A technology of electronic cam and control method, applied in sequence/logic controller program control, electrical program control, packaging automatic control, etc., can solve problems such as reduced efficiency, vibration, and inability to generate asynchronous cam curves in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

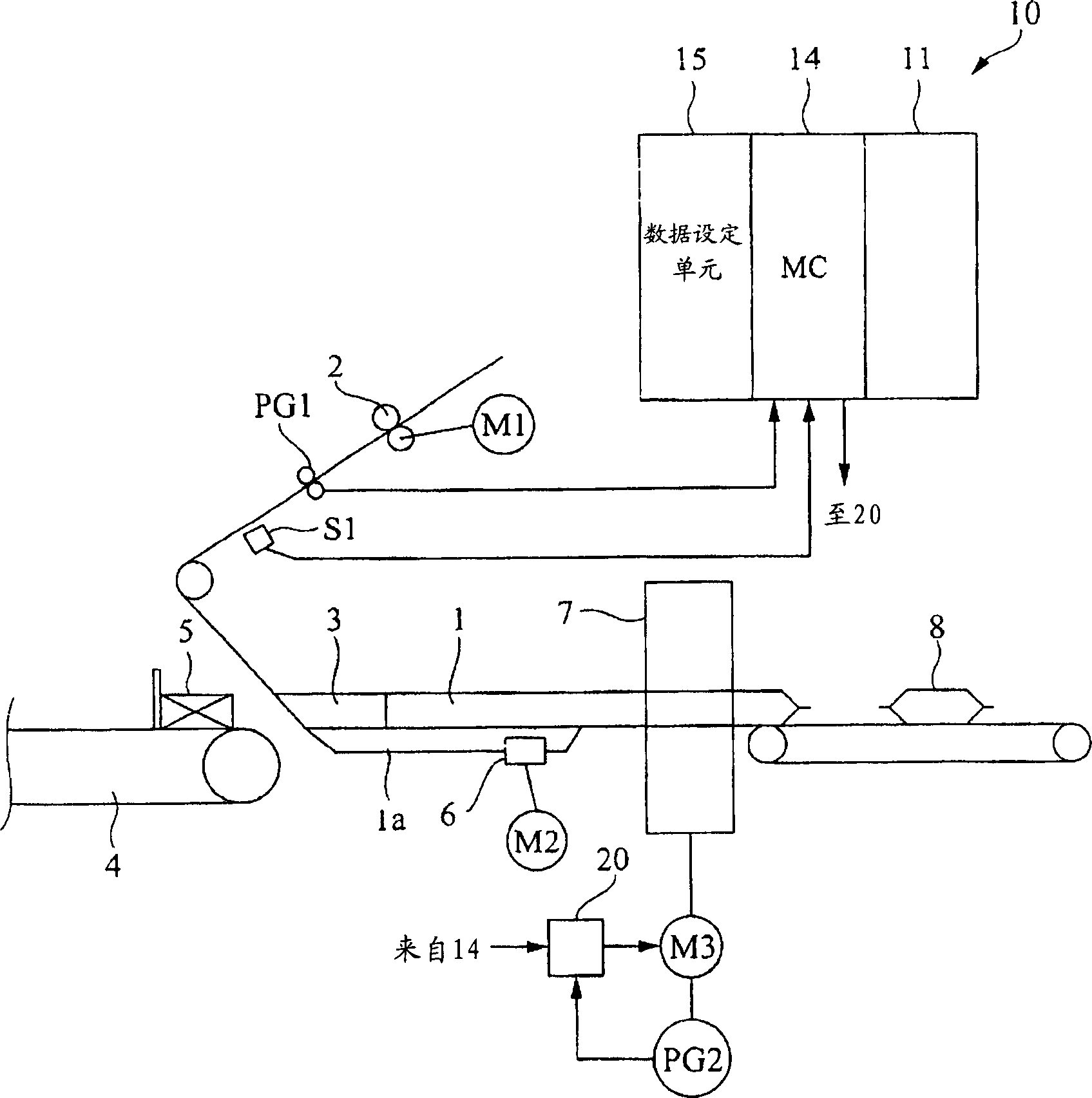

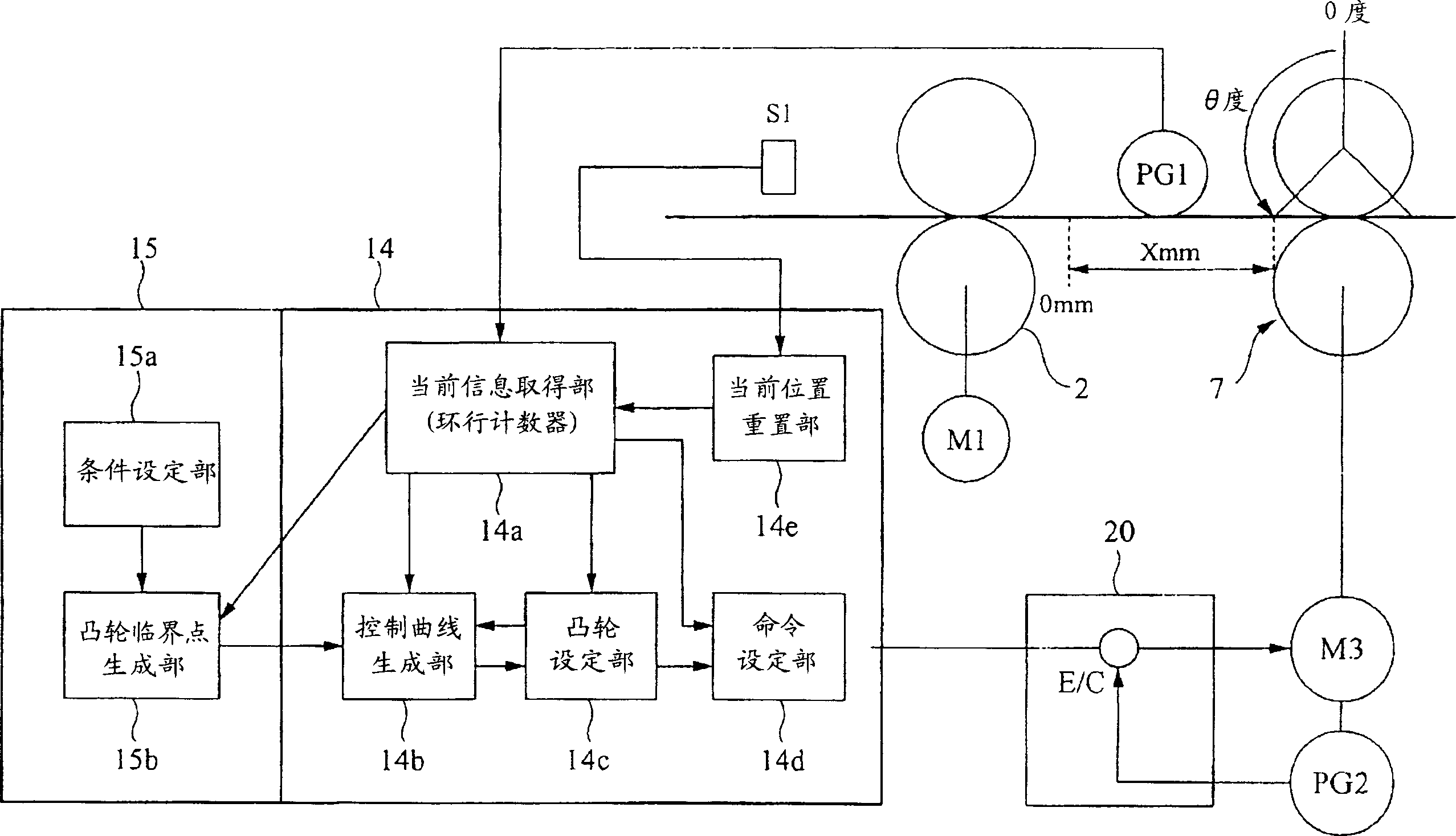

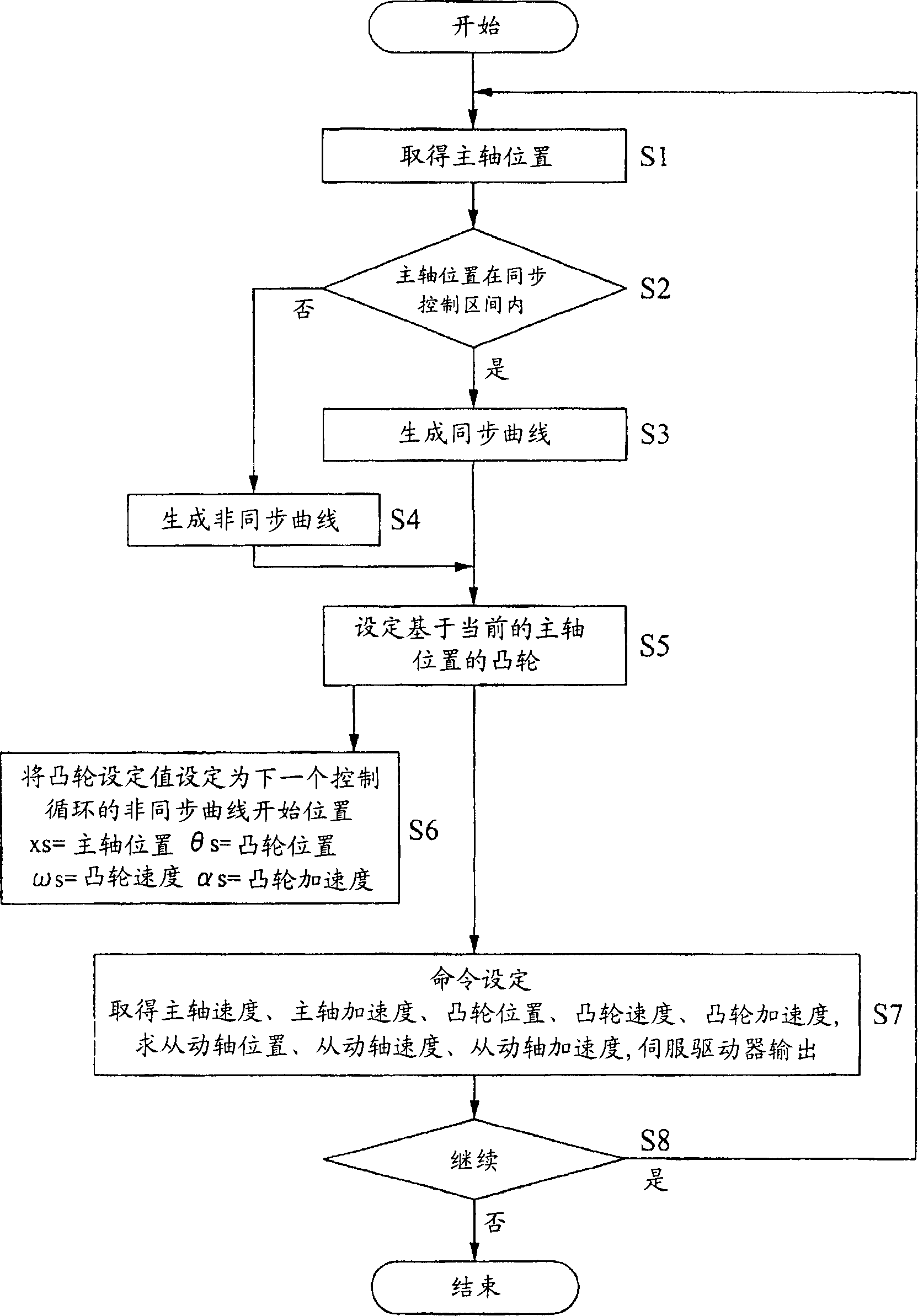

[0067] figure 1 As an example of a control system to which the present invention is applied, a control system for a packaging apparatus is shown. First, the packaging device to be controlled will be described. The packaging film 1 is sandwiched by a pair of feed rollers 2, and is continuously drawn out at a constant speed as the feed rollers 2 rotate. The packaging film 1 thus drawn out is formed into a cylindrical bag by the bag maker 3 . In addition, the packaged objects 5 conveyed at regular intervals with the packaged object conveying and supplying device (finger conveyer) 4 provided on the upstream side of the bag maker 3 are supplied to the bag maker at predetermined timings. 3 inside. Thereby, the to-be-packaged object 5 is contained in the packaging film 1 to be bagged in a cylindrical shape at predetermined intervals, and is conveyed in this state. The center closure device 6 and the end closure device 7 are arranged on the downstream side of the bag maker 3 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com