Printed circuit base plate

A technology for printed circuit substrates and electrical components, which is applied in the fields of printed circuit, printed circuit, printed circuit manufacturing, etc., and can solve problems such as poor connection of connecting pins, heightening of electric bridges, narrowing of intervals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

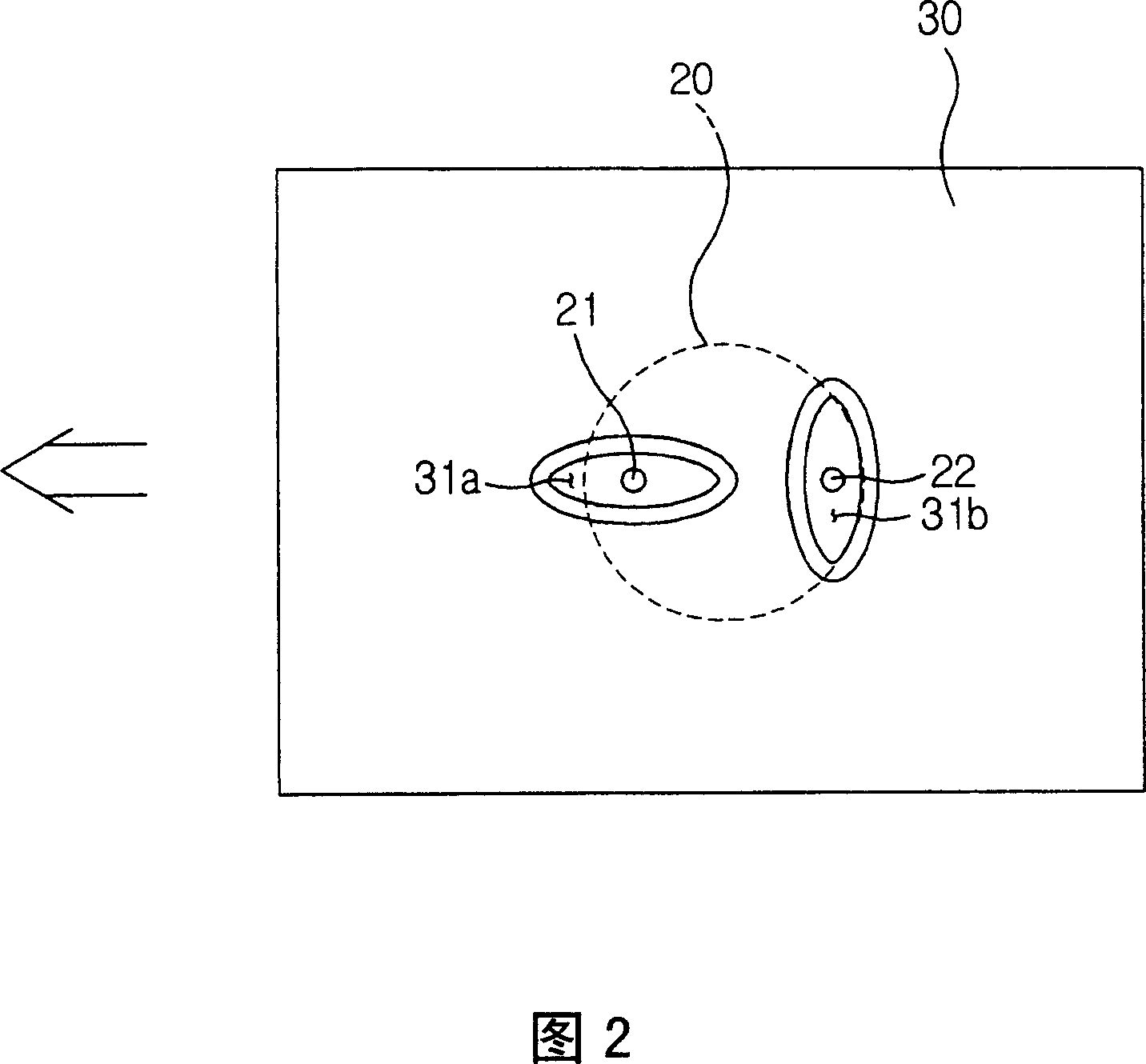

[0025] First, a first embodiment of the present invention will be described with reference to FIG. 1 .

[0026] As shown in the figure, on the printed circuit board 10 in the present invention, a plurality of installation holes 11a, 11b that can install electrical components 20 such as ICs, capacitors, resistors, etc. are provided, and the adjacent parts of the installation holes 11a, 11b are provided. There are a plurality of lands 12 electrically connected to electrical components 20 by soldering with lead-free solder. At this time, at least a pair of connecting pins 21 and 22 that can be inserted through the installation holes 11a and 11b and can be connected by welding are provided on the electrical component. In this embodiment, a pair of connecting pins are provided in parallel on the electrical component 20 Pins 21, 22.

[0027] Therefore, after the connection pins 21, 22 of the electrical component 20 are inserted through the installation holes 11a, 11b of the printed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com