Under water robot structure

A technology of underwater robots and propellers, applied in underwater ships, underwater operating equipment, motor vehicles, etc., can solve the problems of cumbersome procedures and inability to deal with emergencies, and achieve flexible function configuration, low cost, and easy portability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

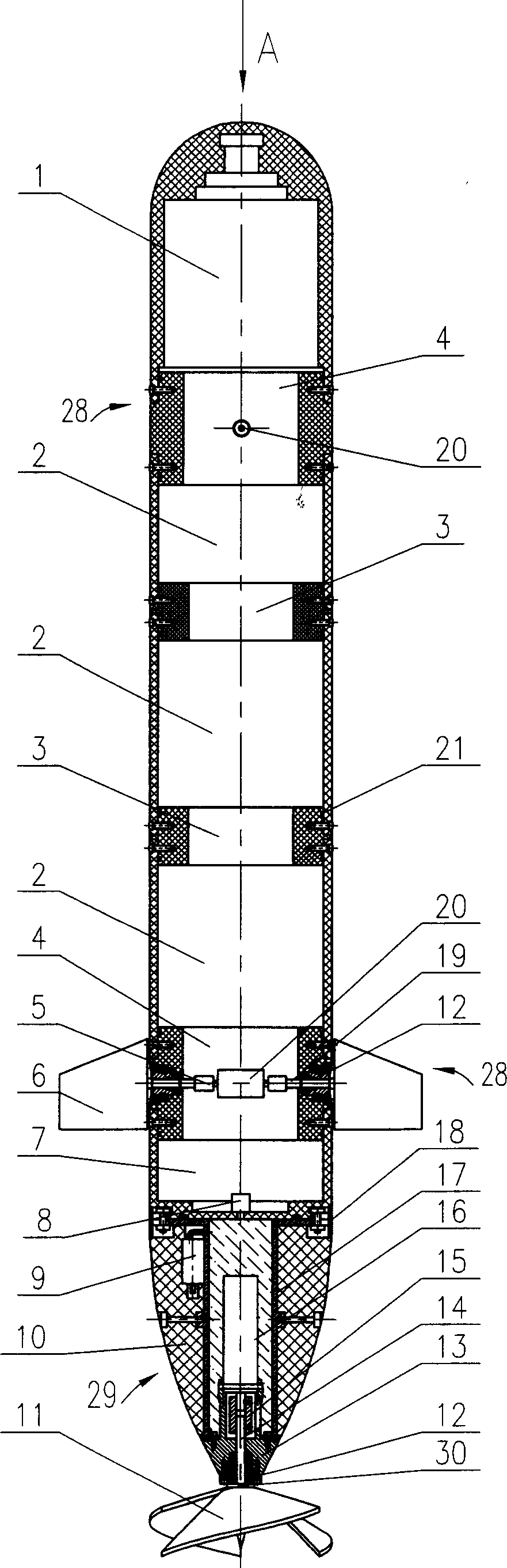

Embodiment 1

[0049] The device is composed of a drainage module 1, a connector 3, a standard load compartment 2, two course adjustment modules 28, and a thruster module 29, and its shape is streamlined (such as Picture 1-1shown); the drainage module 1 is located at the front end of the streamline, as the bow of the underwater robot; the thruster module 29 is located at the tail of the streamline, as the stern of the underwater robot; two course adjustment modules 28 are respectively arranged and installed on the drainage module 1 and the top of the stern connecting compartment 7 in the propeller module 29 (wherein: the rudder stock 19 in one course adjustment module 28 is vertically or intersected with the rudder stock 19 in another course adjustment module 28). A group of standard load cabins 2 are connected through the connecting body 3 and installed between the course adjustment modules 28 as a streamlined intermediate transition part; one course adjustment module 28 is connected with th...

Embodiment

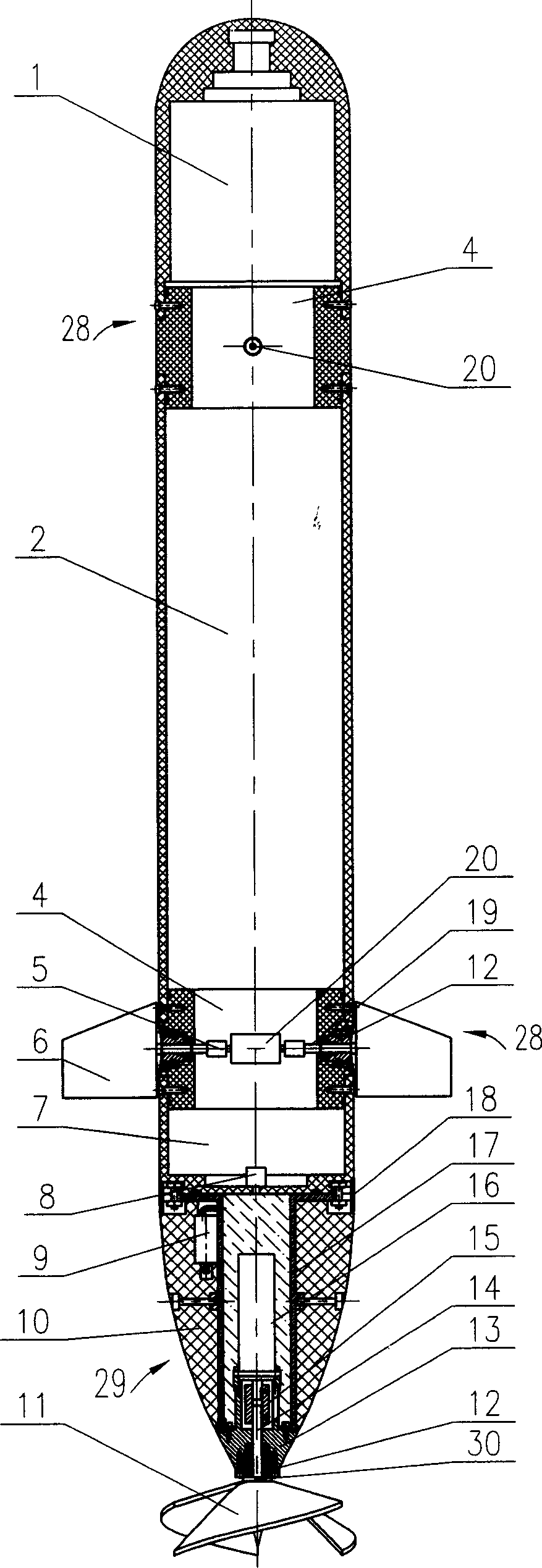

[0072] The difference from Embodiment 1 is that a standard load compartment 2 is installed between the course adjustment modules 28 (such as Figure 1-2 shown).

[0073] Example

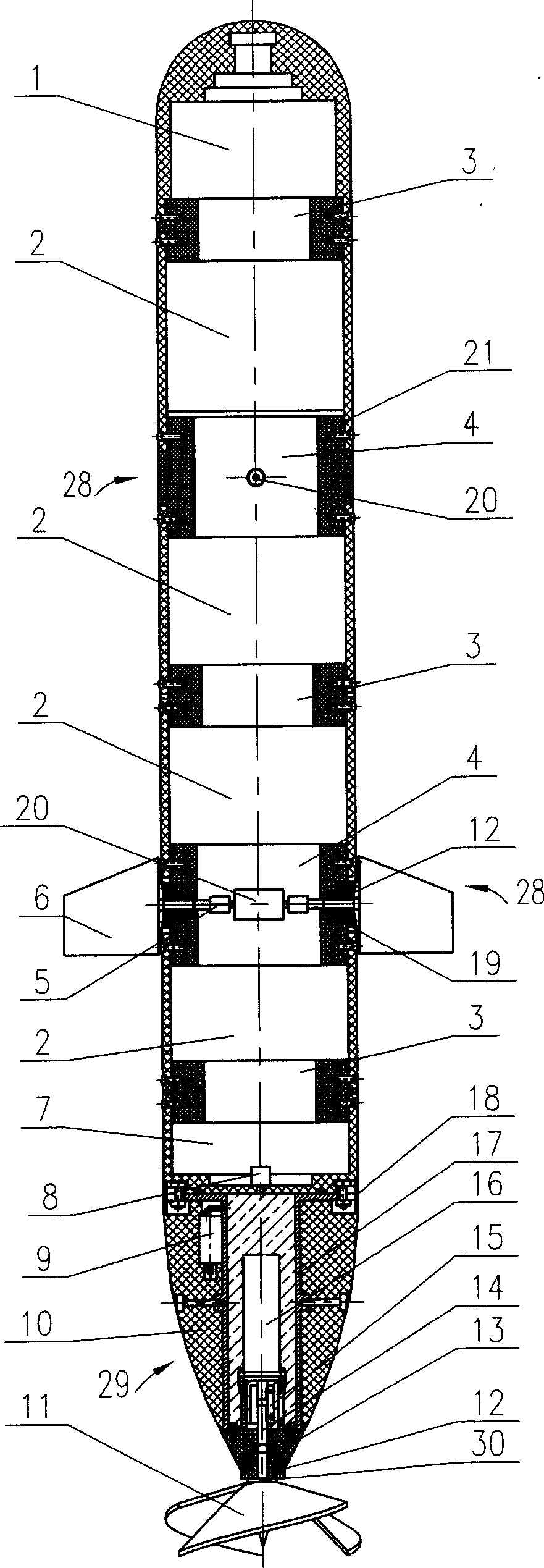

[0074] The difference from Embodiment 1 is that a group of standard load compartments 2 are combined through the connecting body 3 and installed between the course adjustment modules 28, between the course adjustment module 28 and the drainage module 1, and between the course adjustment module 28 and the thruster module 29 (Such as Figure 1-3 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com