Water-permeable drum for the hydrodynamic needling of webs of textile materials, and method for the production of said drum

A knitted fabric, water-permeable technology, applied in the processing of textile material drums, needle looms, textiles and papermaking, etc., can solve problems such as wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

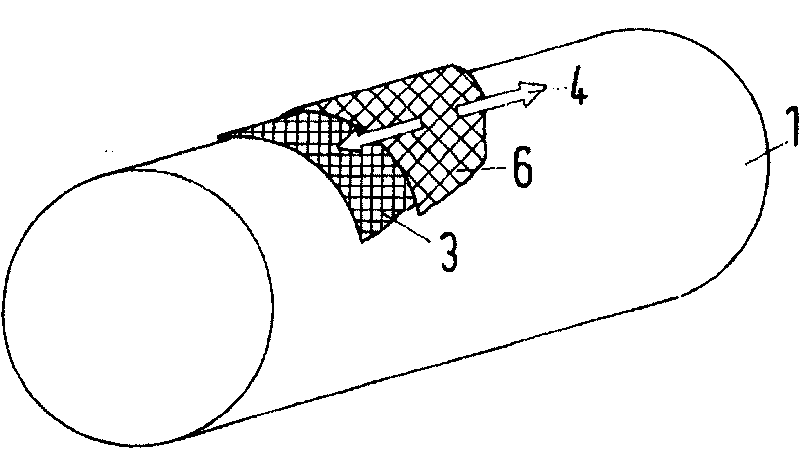

[0024] In the aforementioned EP-A-0 841 424, in figure 1 describes a device in which the textile to be supplied with water jets is guided between two consecutive screens advancing conically toward each other, and whereby the water jets first have to penetrate said one screen in order to be needled. prick. Usually the textile is placed directly on the drum, as in EP-A-1 001 064 figure 2 As shown, and the nozzle bar is arranged directly on the textile with the sprayed water jet. The water-permeable roller according to the structure of the present invention is applicable to the above-mentioned two embodiments.

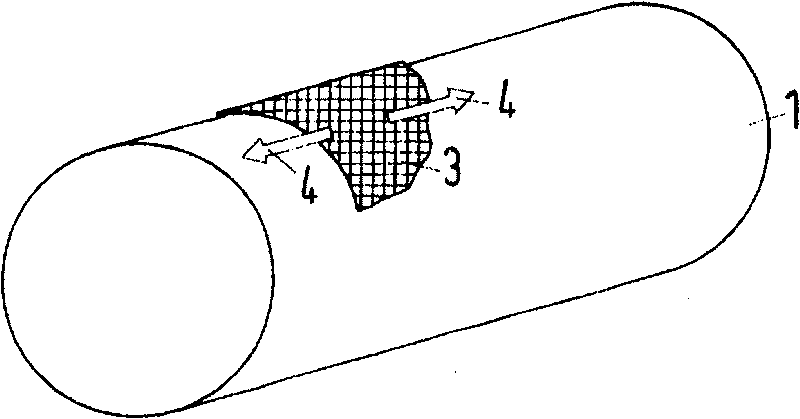

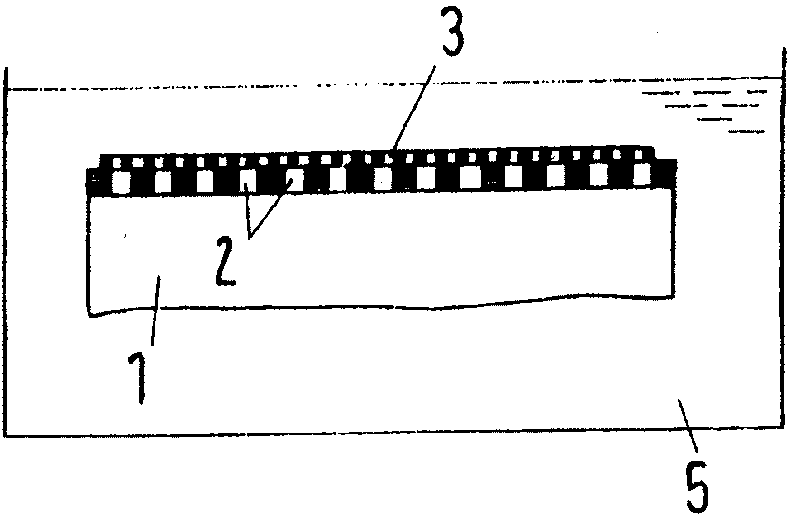

[0025] Screen drum 1 with perforations (perforations 2 in figure 2 shown in ) with its peripheral surface as a component that carries and conveys textiles forward. The perforations in the circumferential surface serve to discharge the water impinging the water jet radially, while the interior of the drum acts as a suction device. In order to be able to act evenly o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com