Dust remover of vacuum cleaner

A dust removal device, vacuum cleaner technology, applied in the direction of suction filter, etc., can solve the problems of poor separation effect between air and coarse dust, shorten the service life of Hypa, increase the filtration capacity of Hypa, etc., to improve the separation efficiency of the first level, strengthen the strength, The effect of improving dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

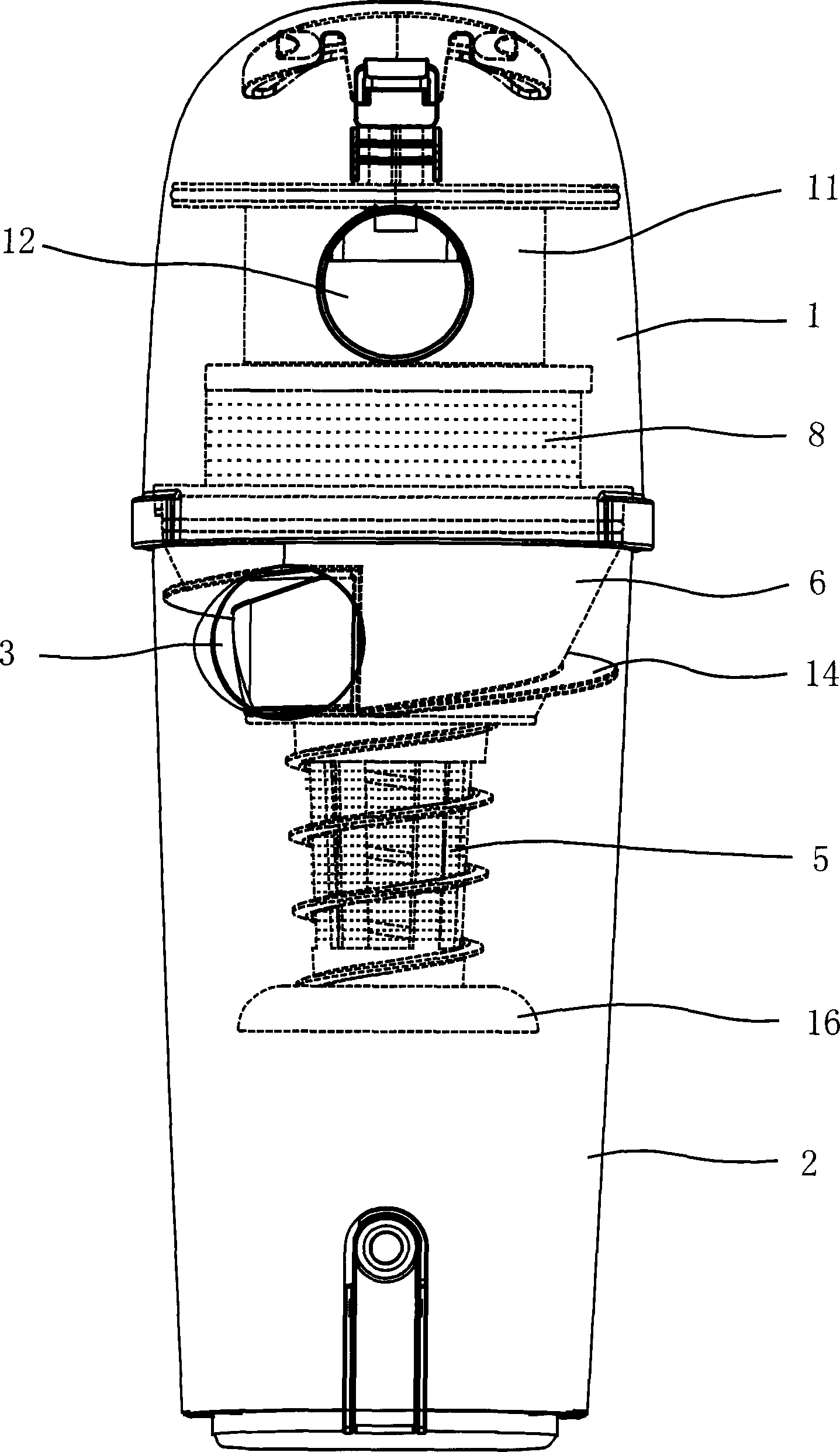

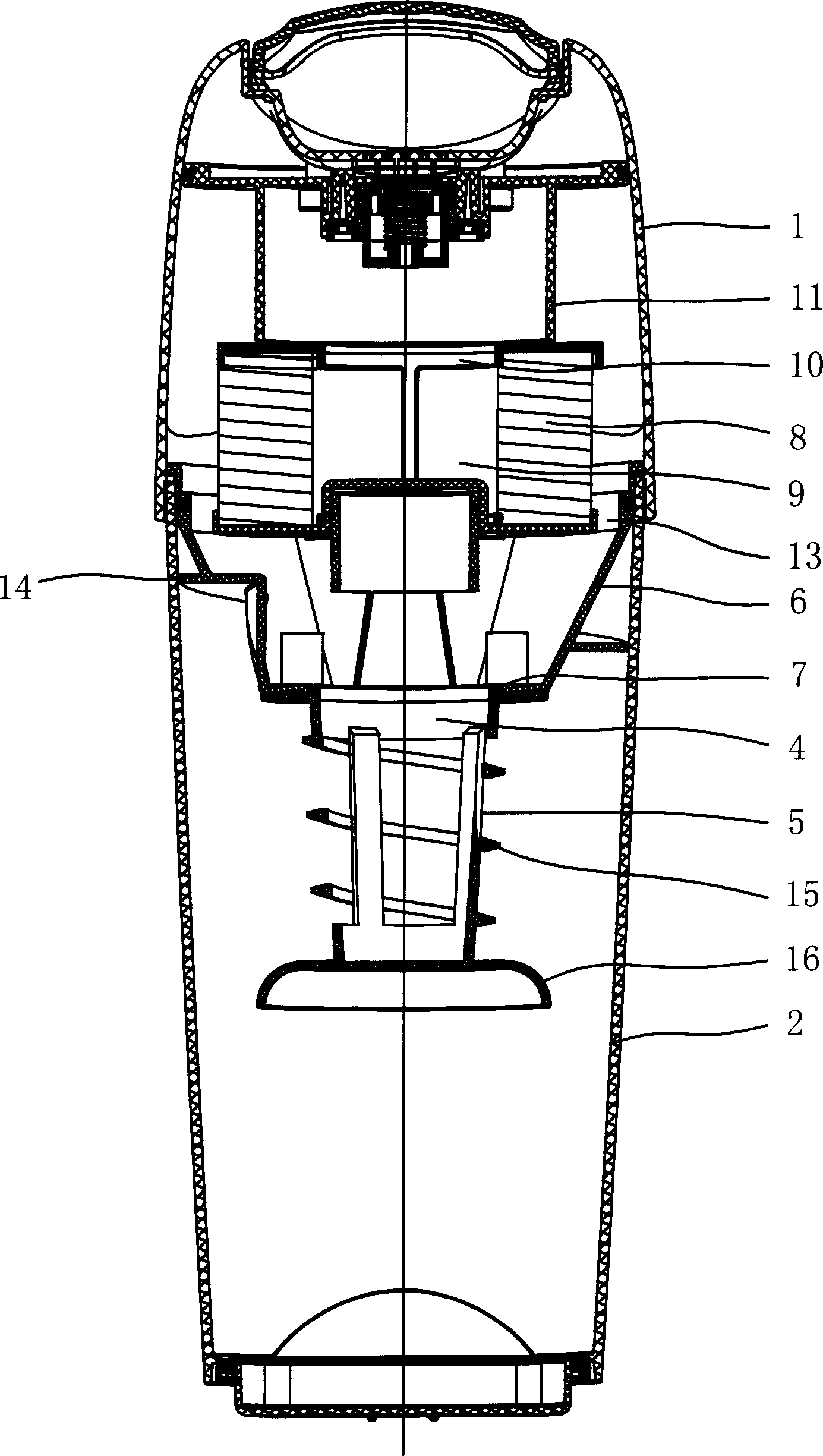

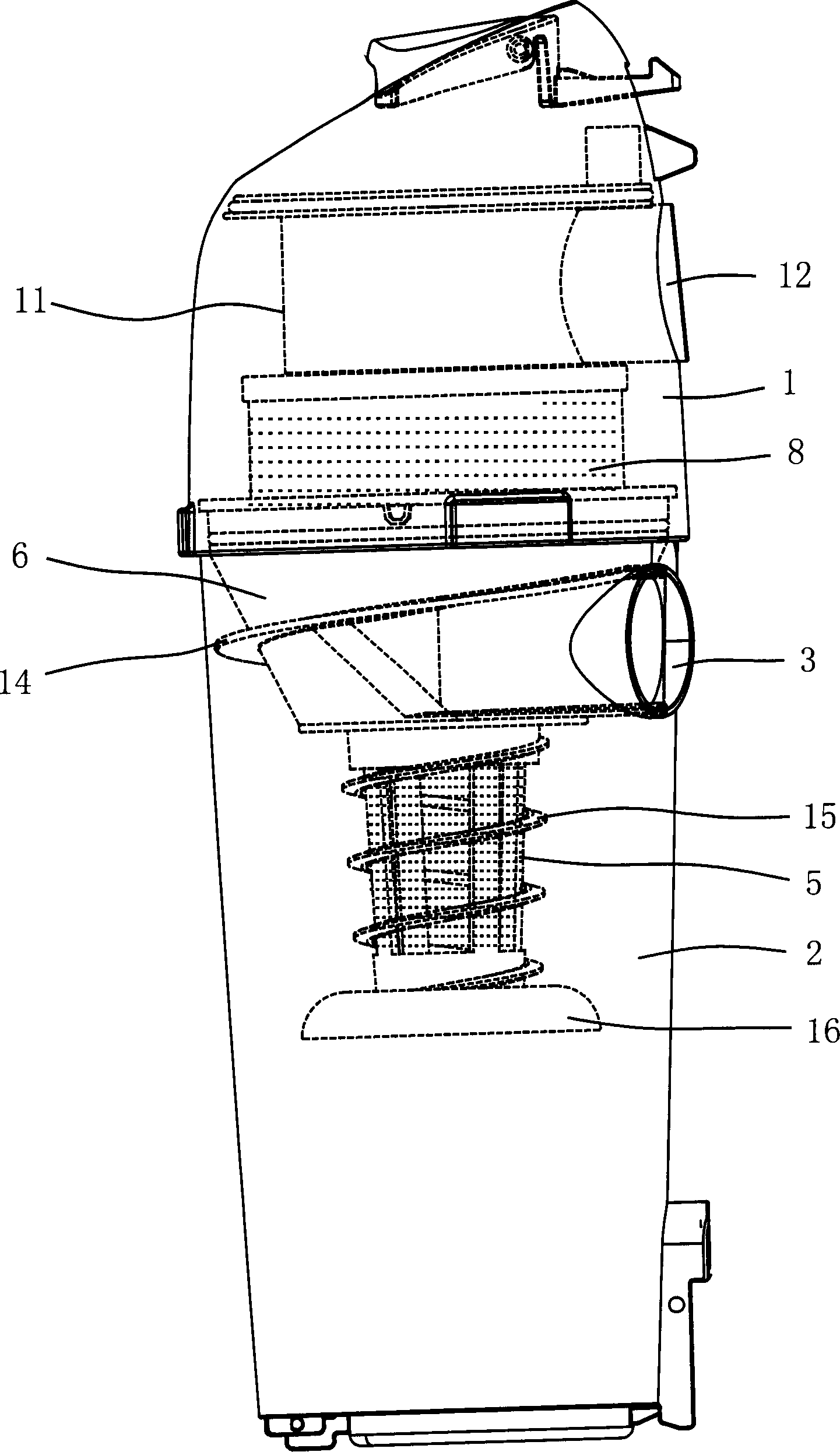

[0019] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a dust removal device for a vacuum cleaner includes a cup cover 1 and a cup body 2. The cup cover 1 is provided with an air outlet 12, and the cup body 2 is provided with an air inlet 3. The cup cover 1 is a transparent body, or a cup The cover 1 is provided with a perspective window, and a partition plate 6 is provided between the cup cover 1 and the cup body 2. The partition plate 6 is in the shape of a cone with a large upper end and a small lower end. The partition plate 6 is provided with an opening 7 for opening The bottom of the hole 7 is connected with a net cover 5, the upper end of the net cover 5 is provided with an opening 4, the opening 4 is docked with the opening 7 on the partition plate 6 and is fixed, and the cup cover 1 above the partition plate 6 is equipped with a cylindrical sea. Handkerchief 8, a gap 13 is provided between the inner wall of the partition plate 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com