Gravity balance type ship vertical lifter

A technology of gravity balance and elevator, applied in the direction of slipway, ship, transportation and packaging, etc., can solve the problems of high energy consumption, complex elevator structure, high construction cost, reduce operating cost, convenient water discharge and sinking, and safe and reliable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

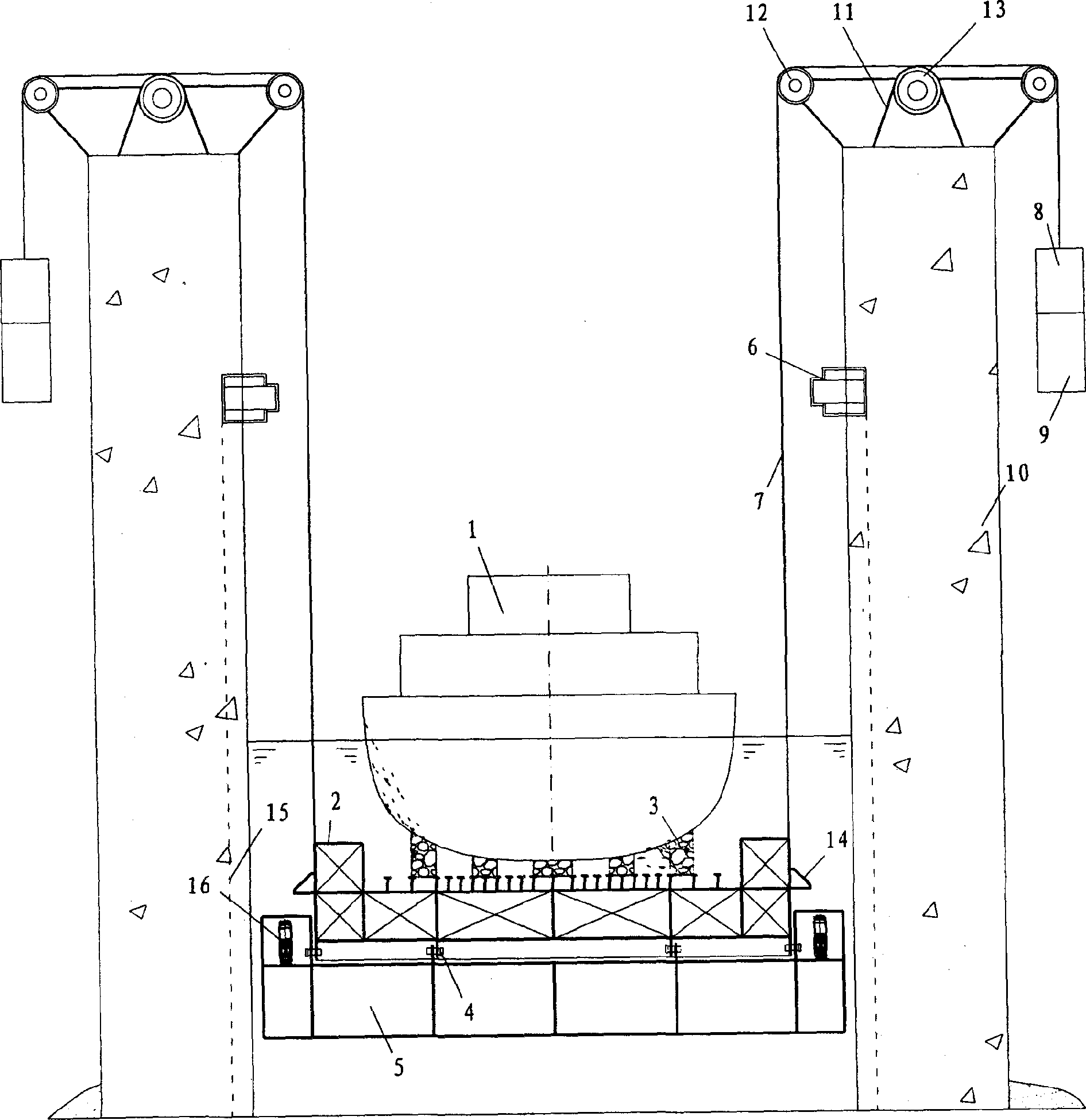

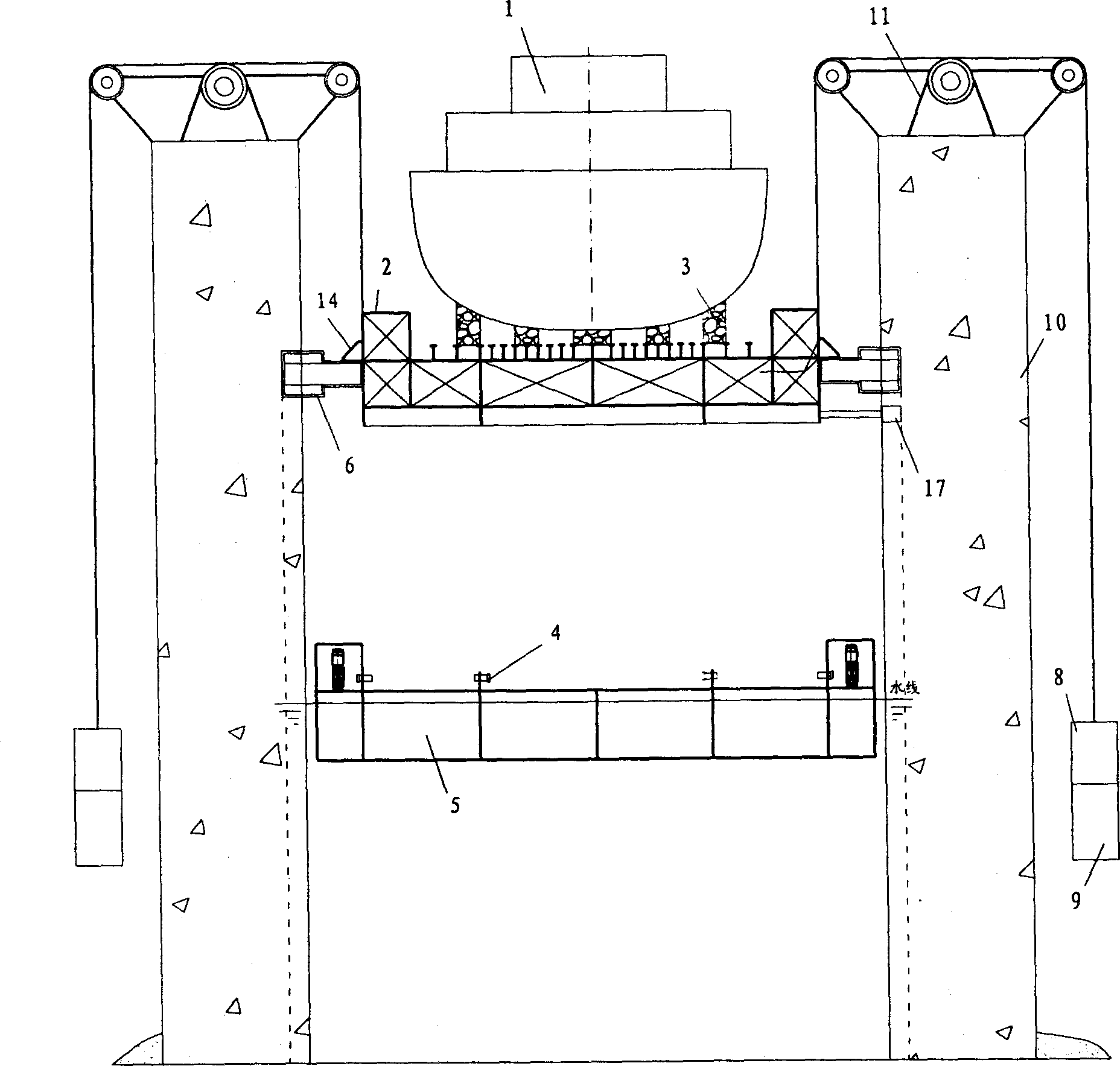

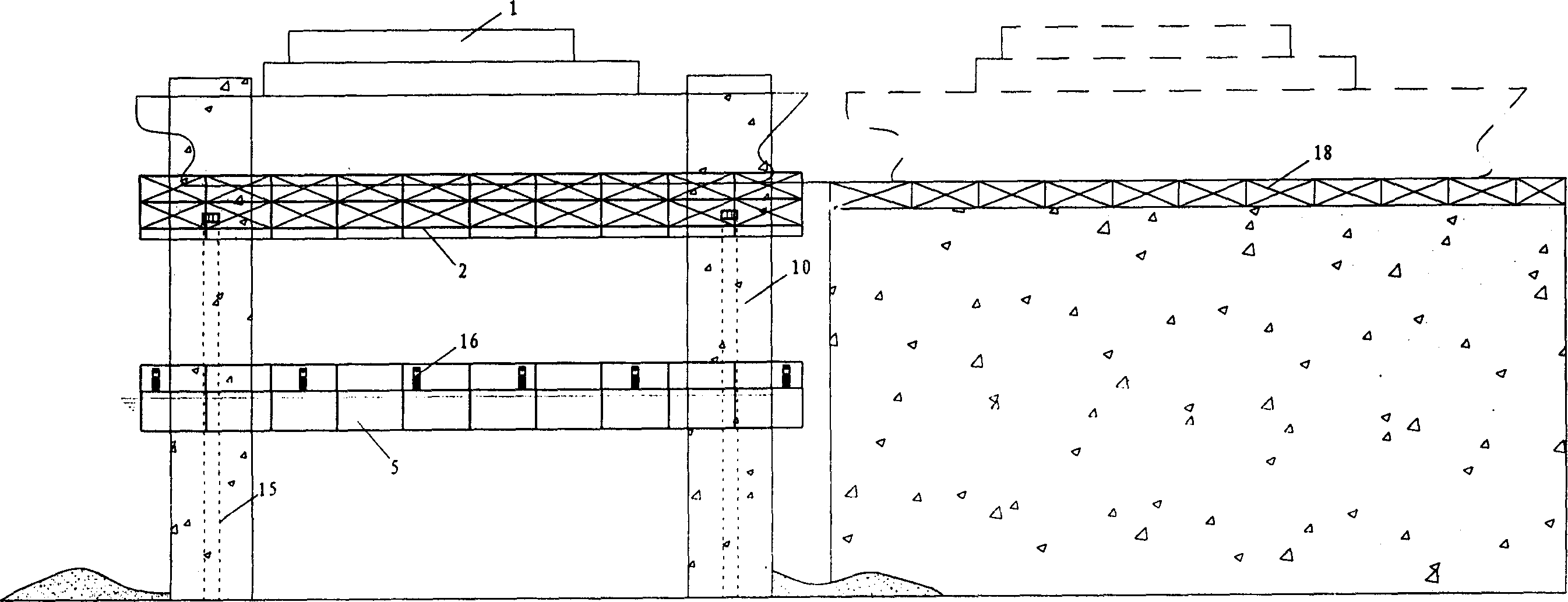

[0012] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. Including tower columns 10 arranged on both sides, the tower columns are 4 to 6, arranged symmetrically at parallel intervals, the tower columns can be made of reinforced concrete, the frame-shaped landing gear 2 is arranged inside the tower columns, and the landing gear is provided with The swing pier 3 and the guide rail are used to shelve the ship 1, and the corresponding tower columns on both sides of the landing gear are equipped with rollers 17, which are configured with the upper and lower lifting limit guide grooves 15 arranged on the inner side walls of the tower columns. The side is also provided with positioning piles 14, and the positioning piles are configured with the locking device 6 arranged on the inner side of the tower column. The bottom of the landing gear is provided with a movable connection device 4, which is connected with the ponto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com