Electronic expansion valve

An electronic expansion valve and valve seat technology, which is applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of large axial size of stopper parts, decline of coil insulation performance, and occupation of installation position, etc., and achieves compact structure, Work smoothly, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

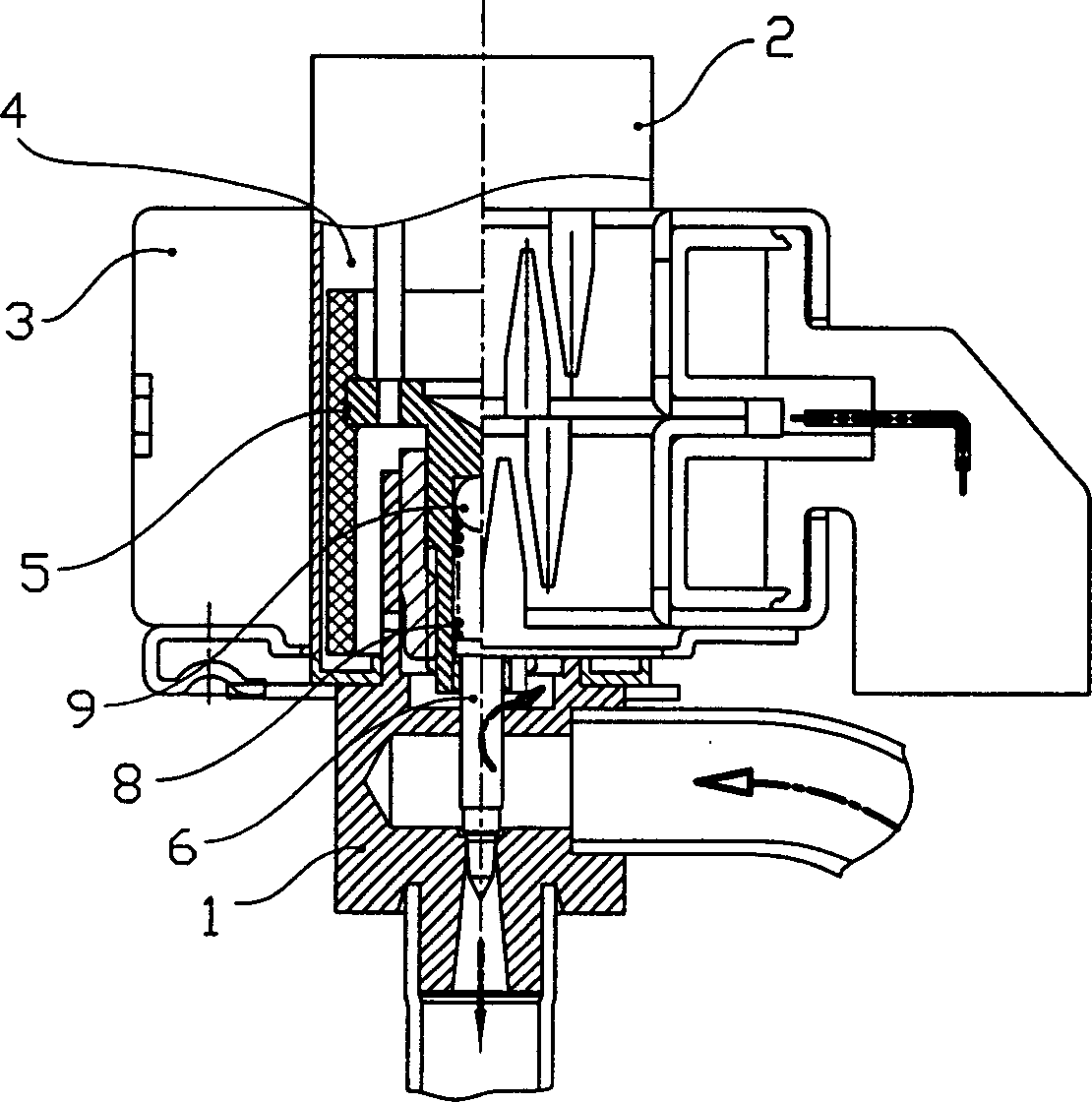

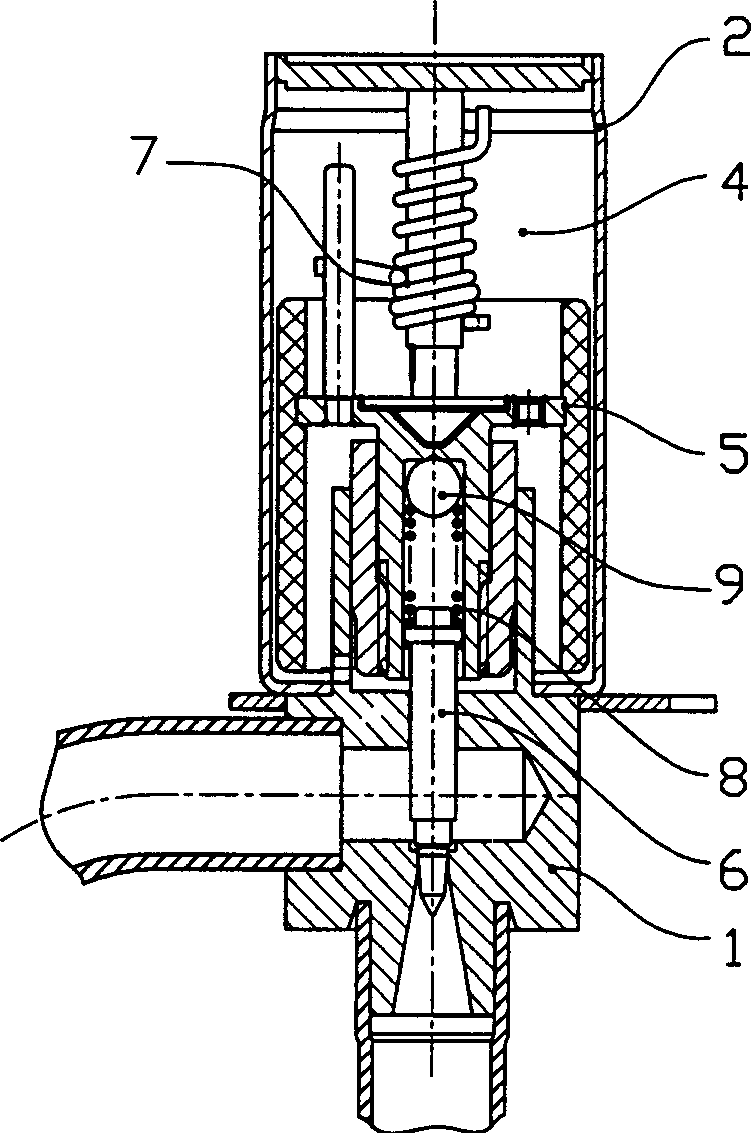

[0028] Such as figure 1 The electronic expansion valve shown mainly includes a valve seat 1, a sleeve 2, a magnetic rotor part 5, a valve stem 6, a stopper part 7 and a coil 3, wherein:

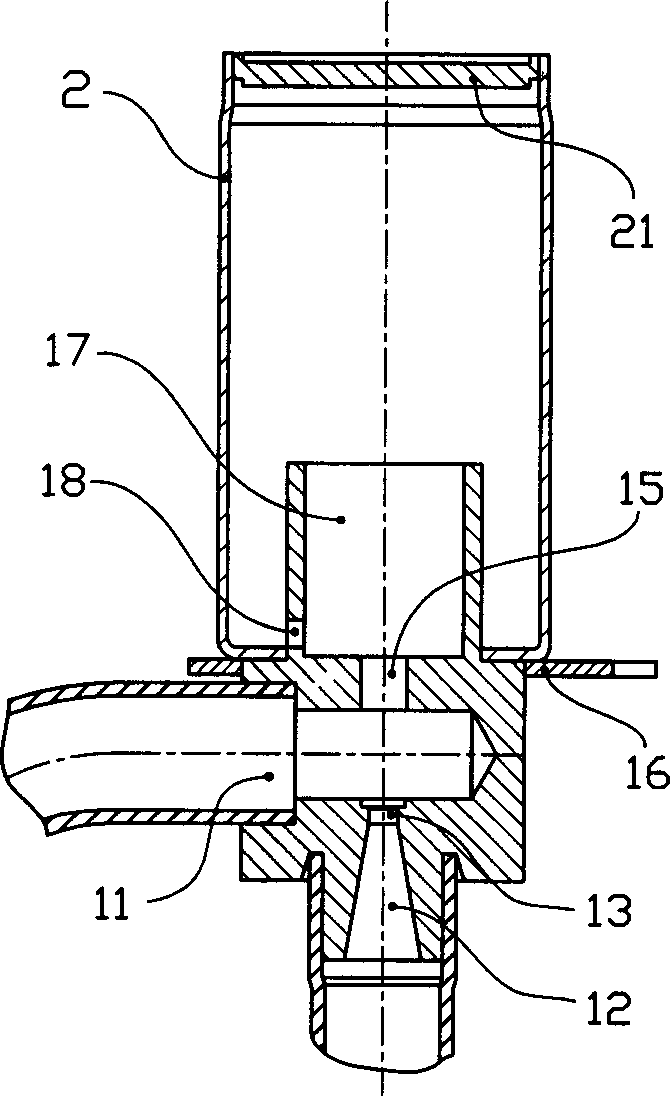

[0029] Such as Figure 9 As shown, the valve seat 1 is provided with an inlet 11, an outlet 12, and a valve port 13 connecting the inlet and the outlet. And the flare angle α adjacent to the valve port is 15 ~ 25 ° bell mouth (see details Figure 9 ), the valve seat 1 is provided with a fixing hole 17, and the fixing hole 17 is press-fitted with a nut 14 through an interference fit. Figure 8 ), the side wall of the fixing hole 17 is provided with a pressure balance hole 18 communicating with the fixing hole and its outer cavity 4, and the valve seat 1 is also provided with a guide hole 15 corresponding to the valve port; the valve seat 1 is welded with The fixed frame 16 is provided with evenly distributed clamping points 16a on the fixed frame 16, and the pitch angle of the clamping poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com