Golf club head

A technology for golf club heads and thick-walled parts, applied to golf balls, golf clubs, rackets, etc., can solve problems such as large amount of bending, decreased durability of the central part, and easy damage, so as to improve rigidity and impact performance , the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

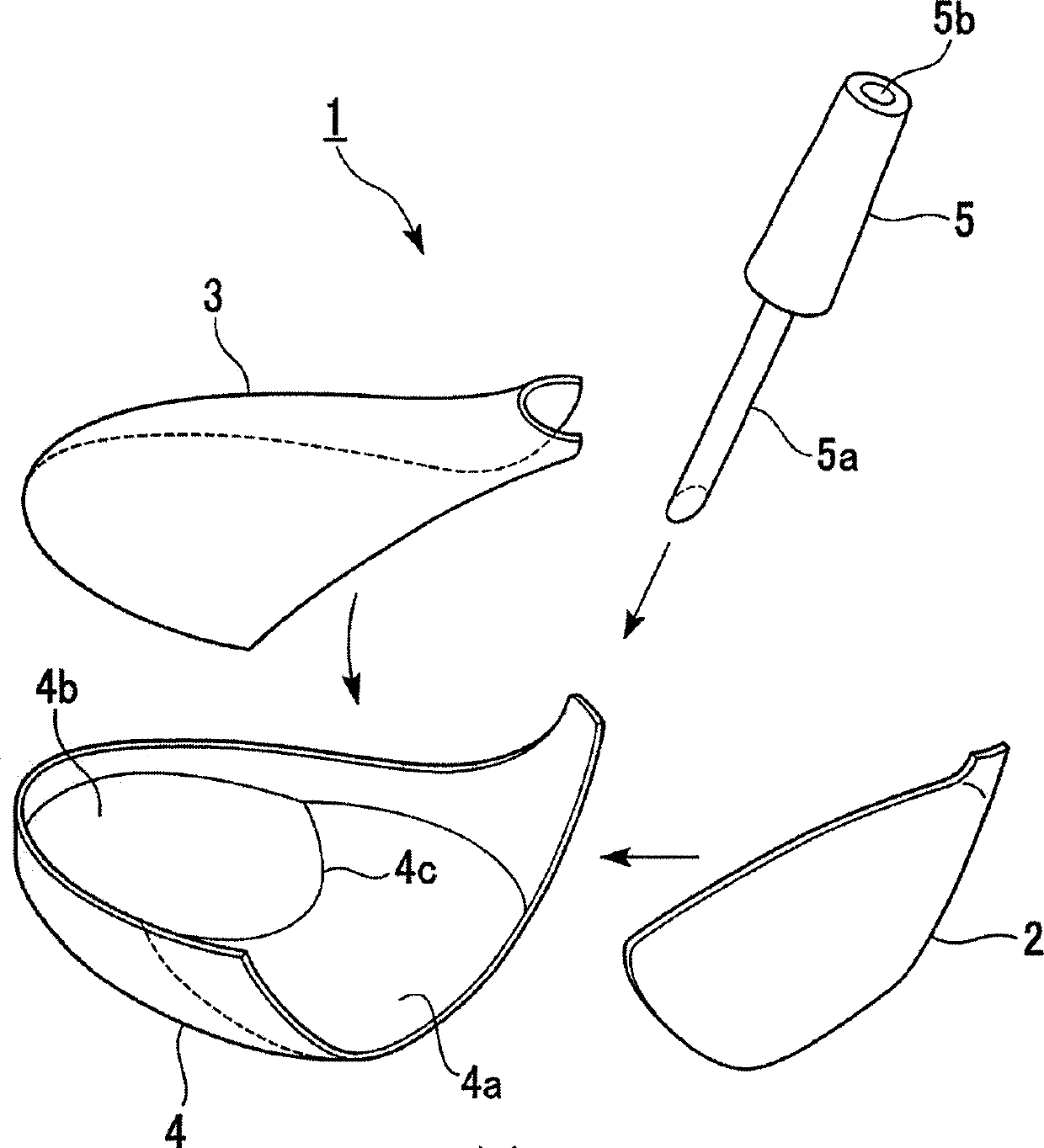

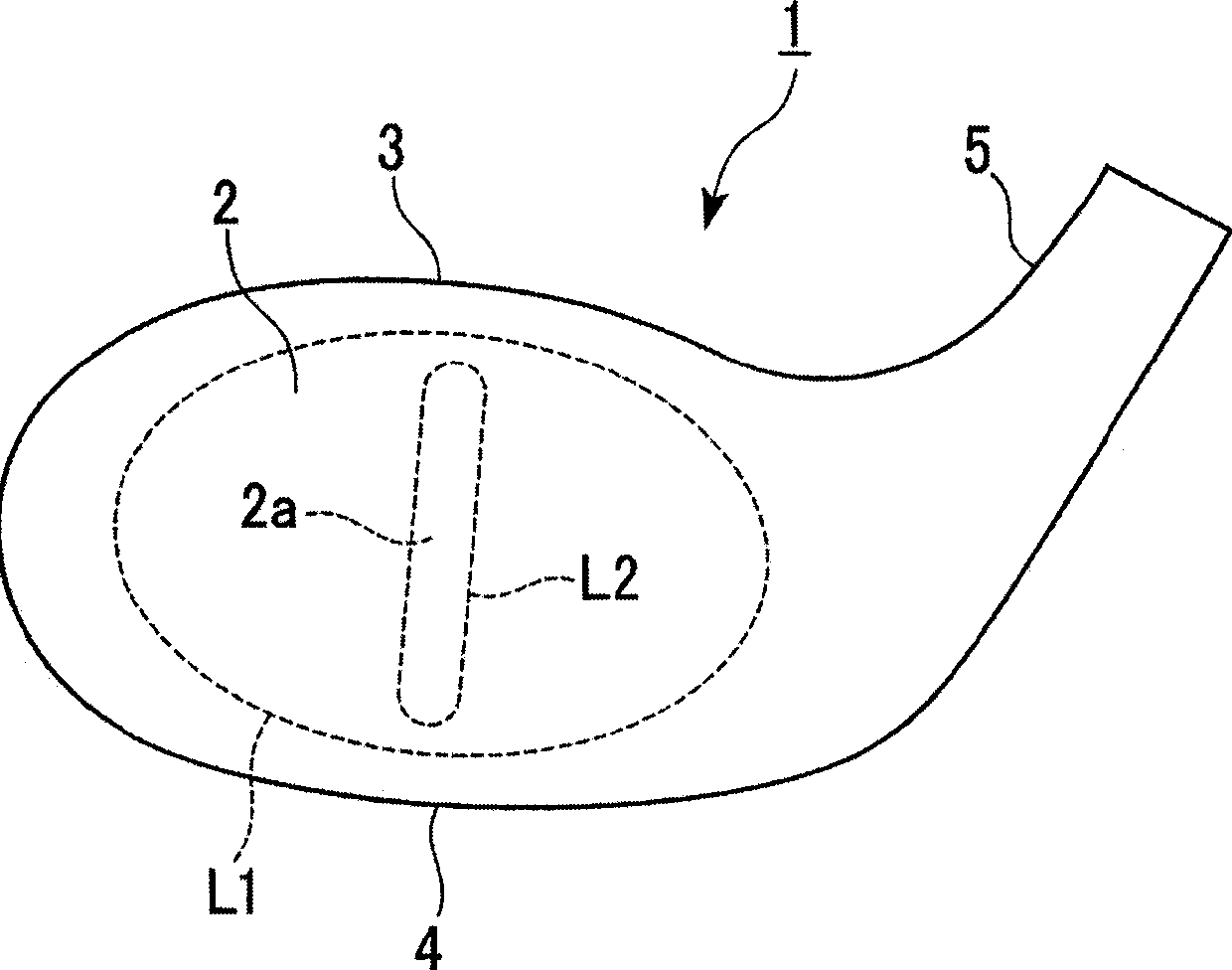

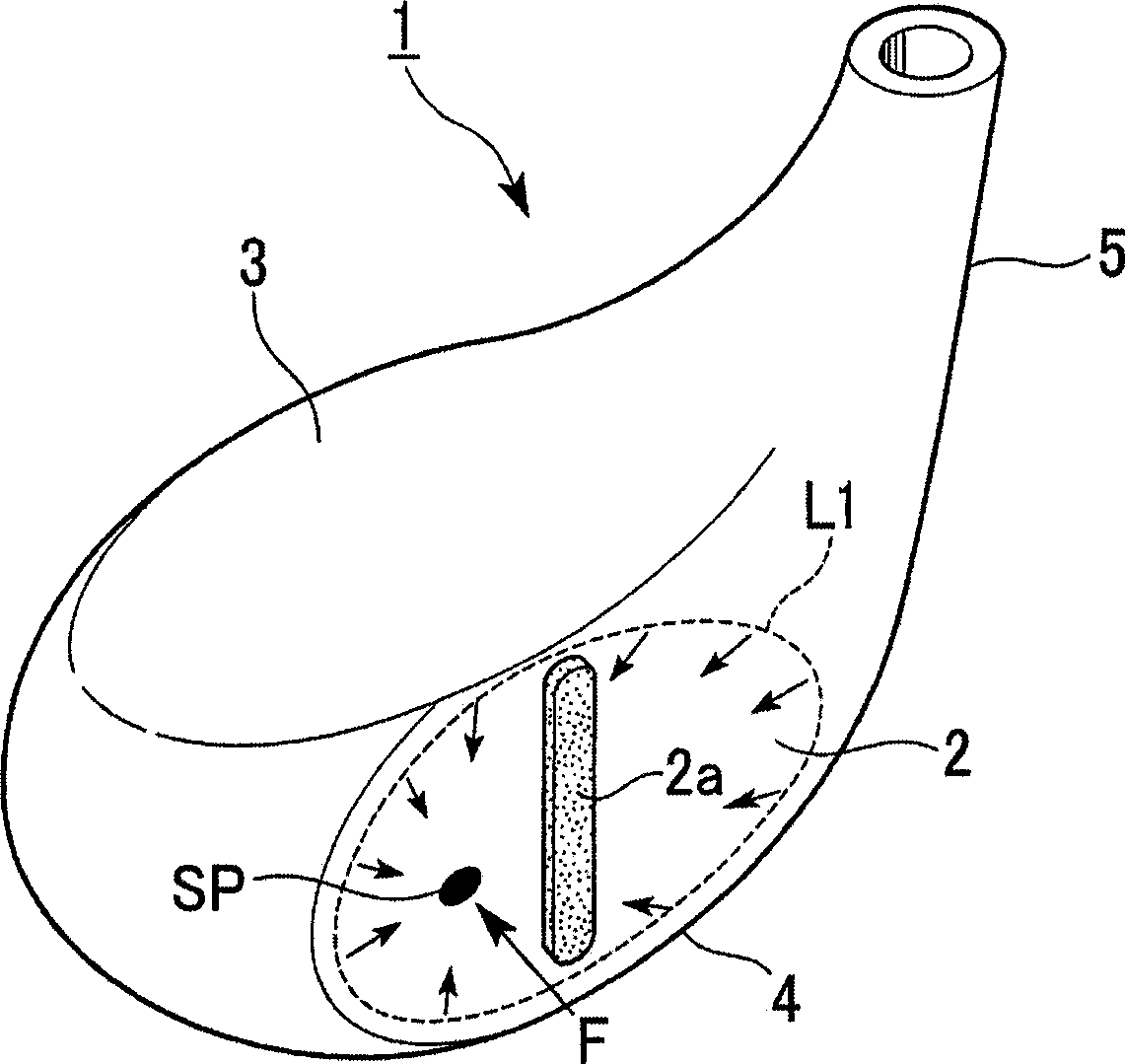

[0050] 1 to 3 are diagrams showing the structure of the club head body of the metal shell structure according to the first embodiment of the present invention. The face shell 2, the crown shell 3, the sole shell 4, and the shaft connecting portion are joined and assembled by welding. The open end portions of the shells 5 are respectively opposite, and the golf club head 1 is completed by grinding the joint portion. In addition, the end of the extension part 5a of the rod connection part casing 5 is welded to the inner bottom of the bottom casing 4, and on the other hand, the end of the rod is inserted into the core hole 5b formed in the rod connection part casing 5 and fixed, Complete golf clubs.

[0051] In addition, a thick portion 2a is formed in advance in the longitudinal direction substantially in the center of the inner surface of the face shell ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com