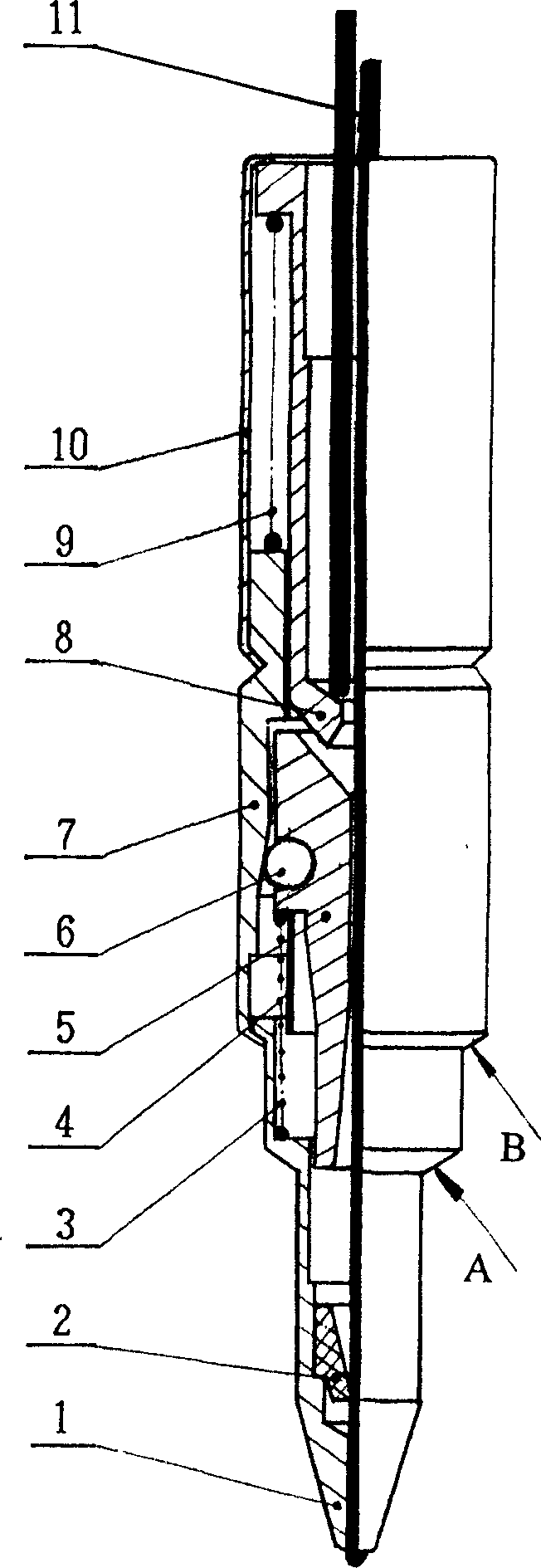

Full automatic propelling pencil and lead assembly

A pencil lead, fully automatic technology, applied in the field of core components, can solve the problems of short service life, plastic aging, deformation, etc., to achieve the effect of good coaxiality, easy production, and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

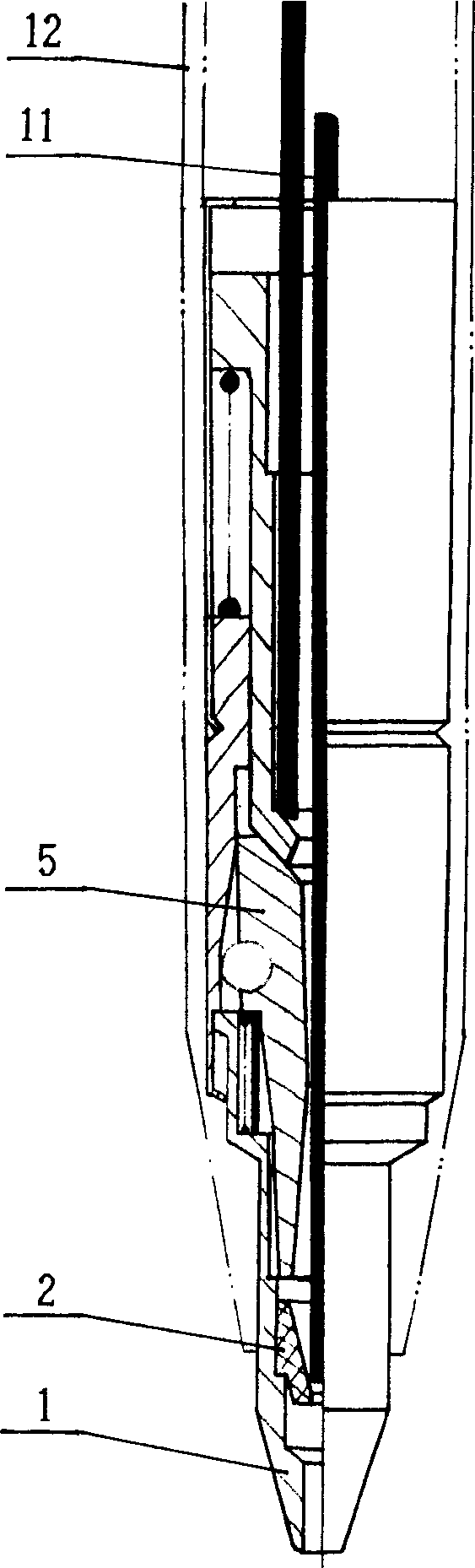

[0011] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

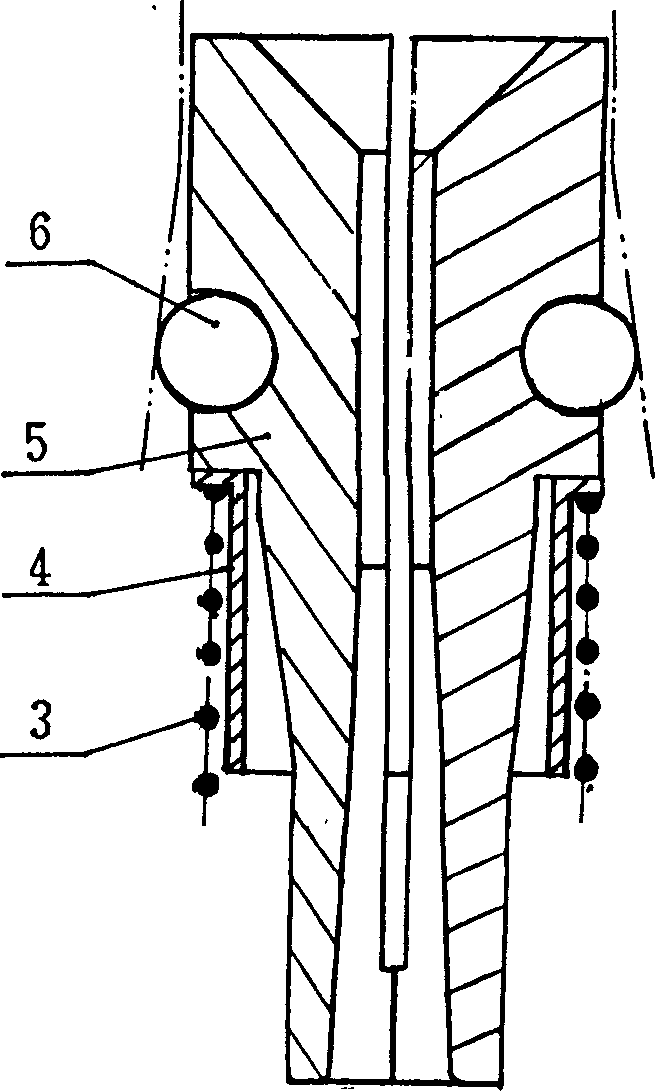

[0012] The sandwich block 5 is composed of two symmetrical lobes, which are injection-molded with high-engineering plastics. After the sandwich is closed, the two ends of the sandwich form two conical holes with a large outer and a smaller inner. The holes just close together without gaps, and the sandwich part is between the two tapered holes. There is a stepped surface in the middle of the outer surface to cooperate with one end surface of the spring seat 4, and the two petals of the clamping block are synchronized to prevent axial misalignment to ensure reliable clamping. There are two symmetrical arc-shaped grooves on the outer surface of the core block 5 to place the steel ball 6 .

[0013] Protective nozzle 1, with a stepped hole in the middle, the small end is conical, the large end is stepped cylindrical, and the outer surfaces A and B of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com