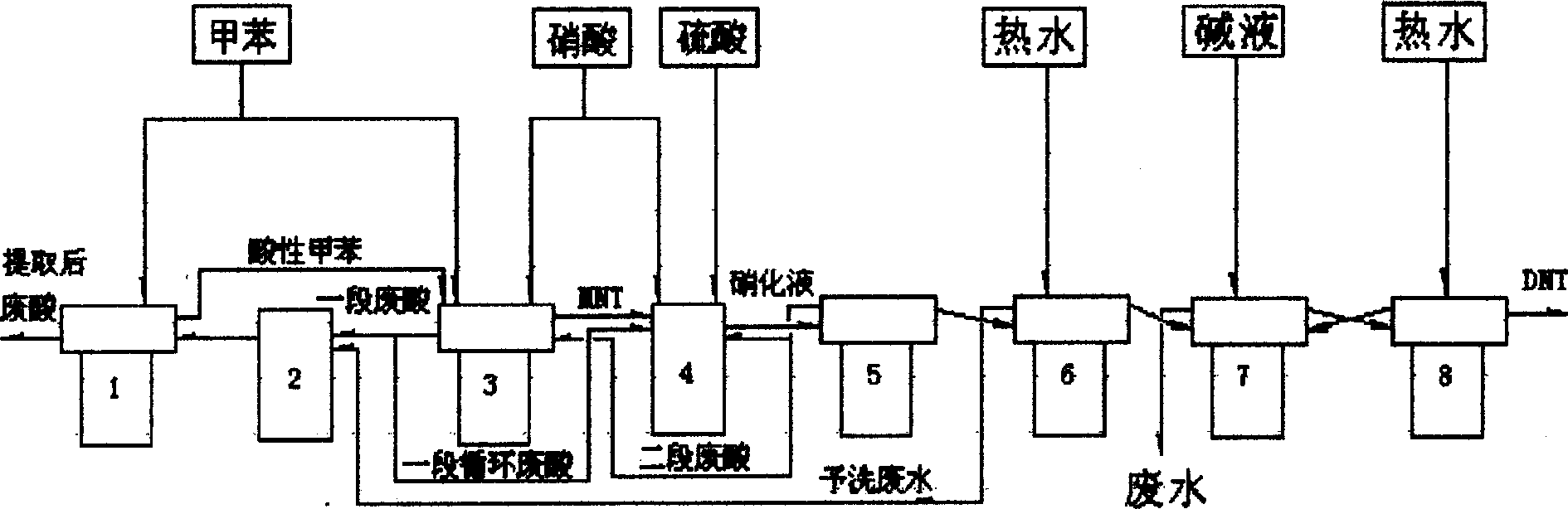

Process for continuous preparing diruitro methylbenzele and apparatus thereof

A technology for dinitrotoluene and nitrotoluene, which is applied in the field of continuous preparation of dinitrotoluene and its devices, can solve the problems of many by-products, long routes and many equipment, and achieves the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

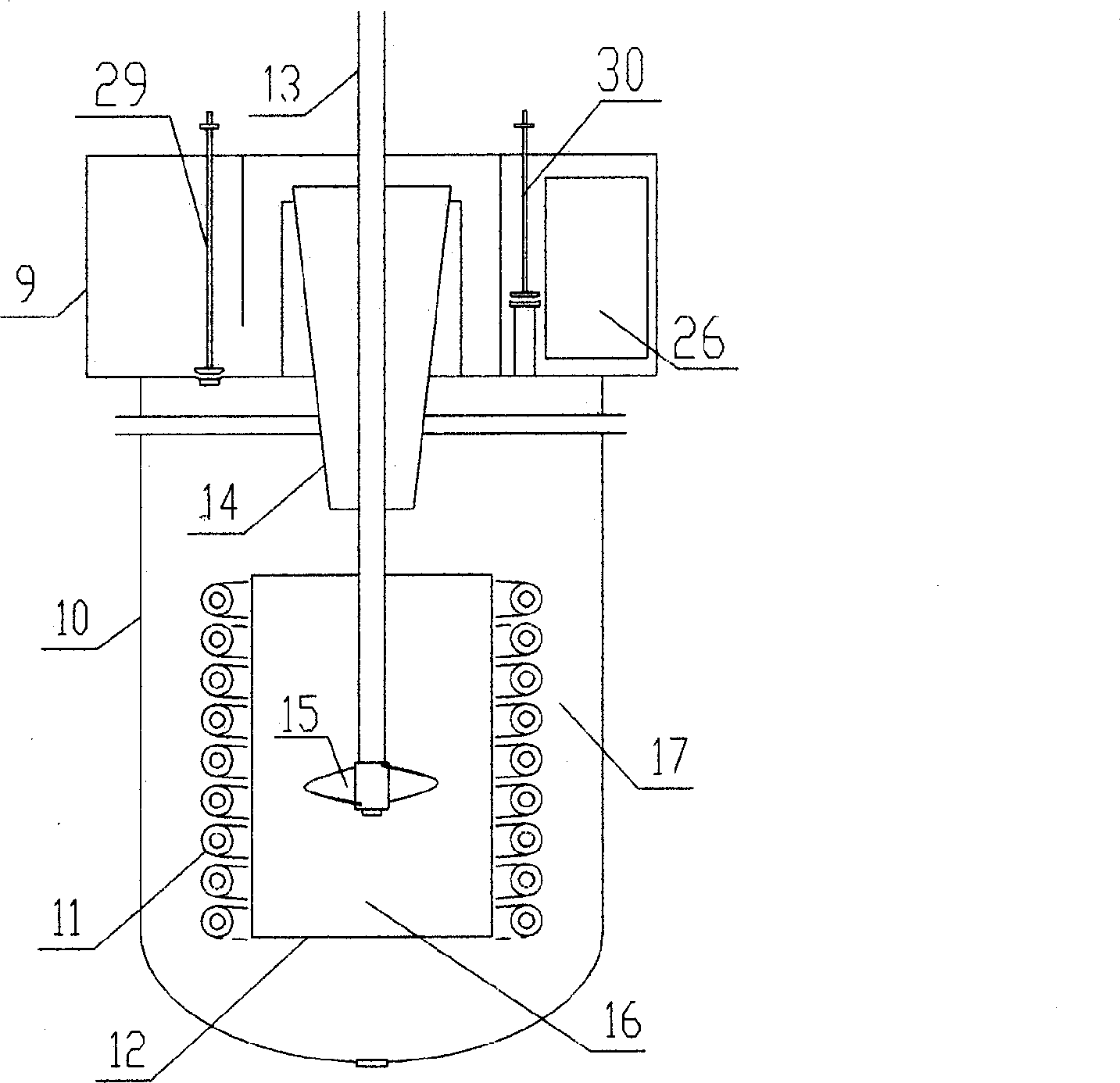

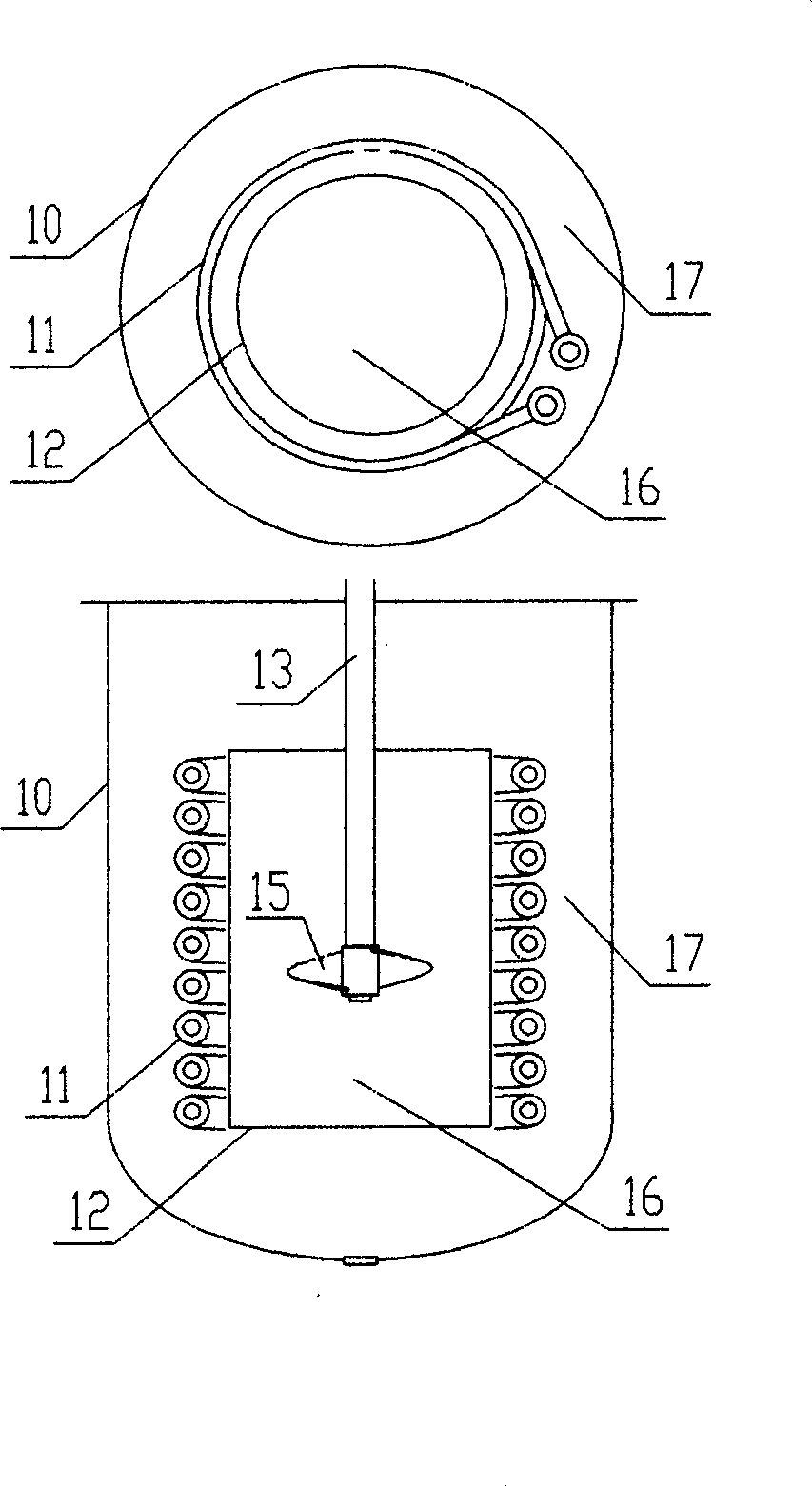

[0060] The diameter of the reaction kettle is 180cm, and the height is 270cm; the diameter of the guide tube in the reaction kettle is 105cm, and the area of the stirring zone is 0.87m 2 , the circulation area is 0.98m 2 , the ratio of the area of the two zones is 1:1.3; 3 / min, the flow velocity in the stirring zone is 1.11m / s, the flow velocity in the circulation zone is 0.98m / s, and the ratio of the flow velocity in the two zones is 0.98.

[0061] The diameter of the separator is 240cm, the height is 80cm, and the separation area is 4m without disc separator 2 Left and right, after adding a group of disc separators with an angle of 120 degrees, an interval of 25 mm between the steel plates, an angle of 45 degrees between the steel plate and the bottom plane of the separator, and a height of 70 cm, the separation area is 27 m 2 The separation area has increased by nearly 7 times; the diameter of the valve seat of the waste acid circulation device in the separator is 50...

Embodiment 2

0.0

0.0

[0069] best practice

[0070] The diameter of the reactor is 130cm, and the height is 240cm; the diameter of the diversion tube in the reactor is 50cm, and the area of the stirring zone is 0.19m 2 , the area of the circulation zone is 0.27m 2 , the ratio of the area of the two areas is 1:1.4; 3 / min, the flow velocity in the stirring zone is 1.92m / s, the flow velocity in the circulation zone is 1.35m / s, and the ratio of the flow velocity in the two zones is 0.7.

[0071] The diameter of the separator is 160cm, the height is 60cm, and the separation area is 1.88m without disc separator 2 Left and right, add a set of disc-type separation devices with an angle of 120 degrees, an interval of 25 mm between the steel plates, an angle of 45 degrees between the steel plate and the bottom plane of the separator, and a height of 55 cm. The separation area is 7.5 m 2 The separation area has increased by about 4 times; the diameter of the valve seat of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com