Direct type back light module

A backlight module, direct type technology, applied in optics, nonlinear optics, mirrors, etc., can solve the problems of dark band overall backlight module light, the uniform effect of light is not easy to control, and the uniformity is not enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

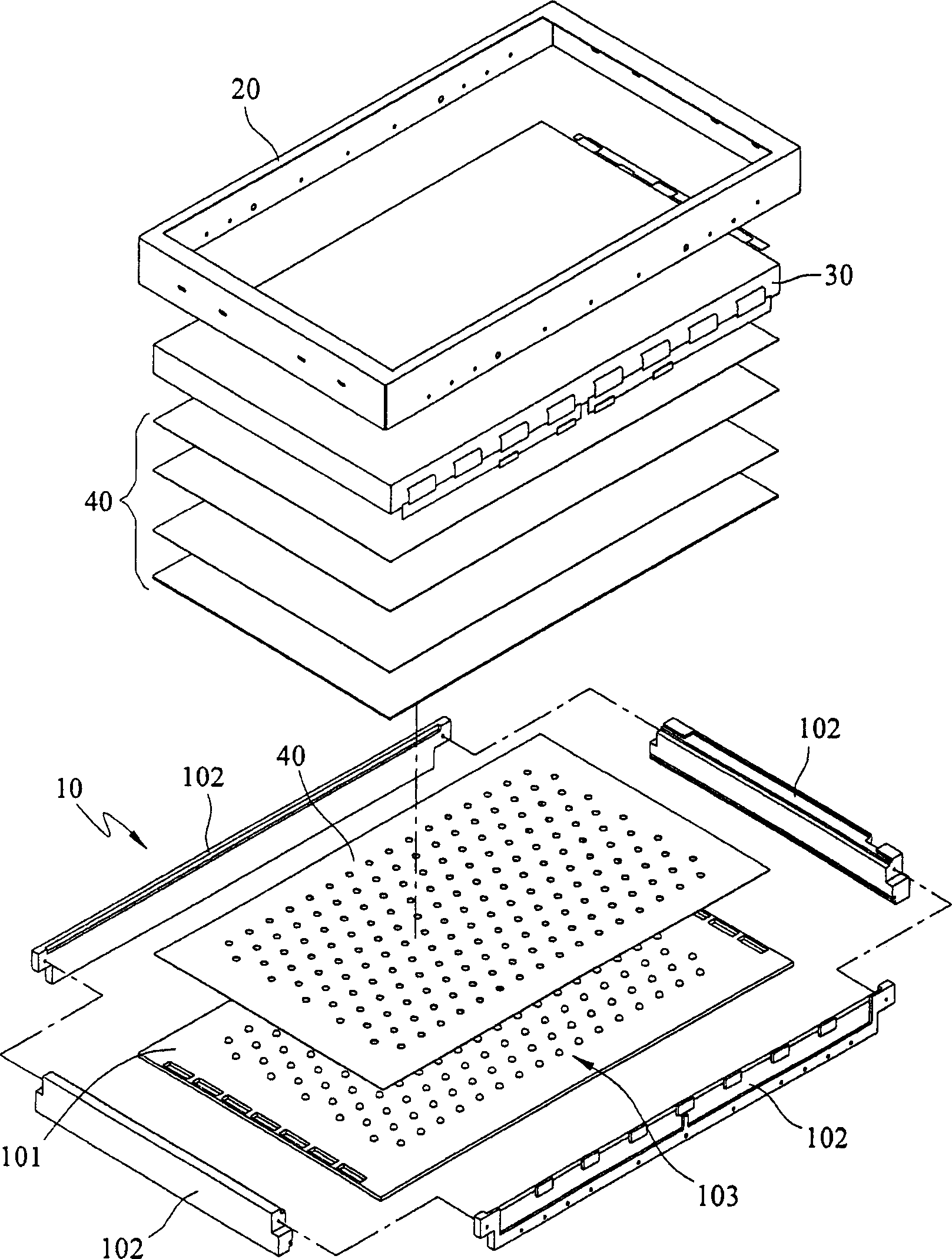

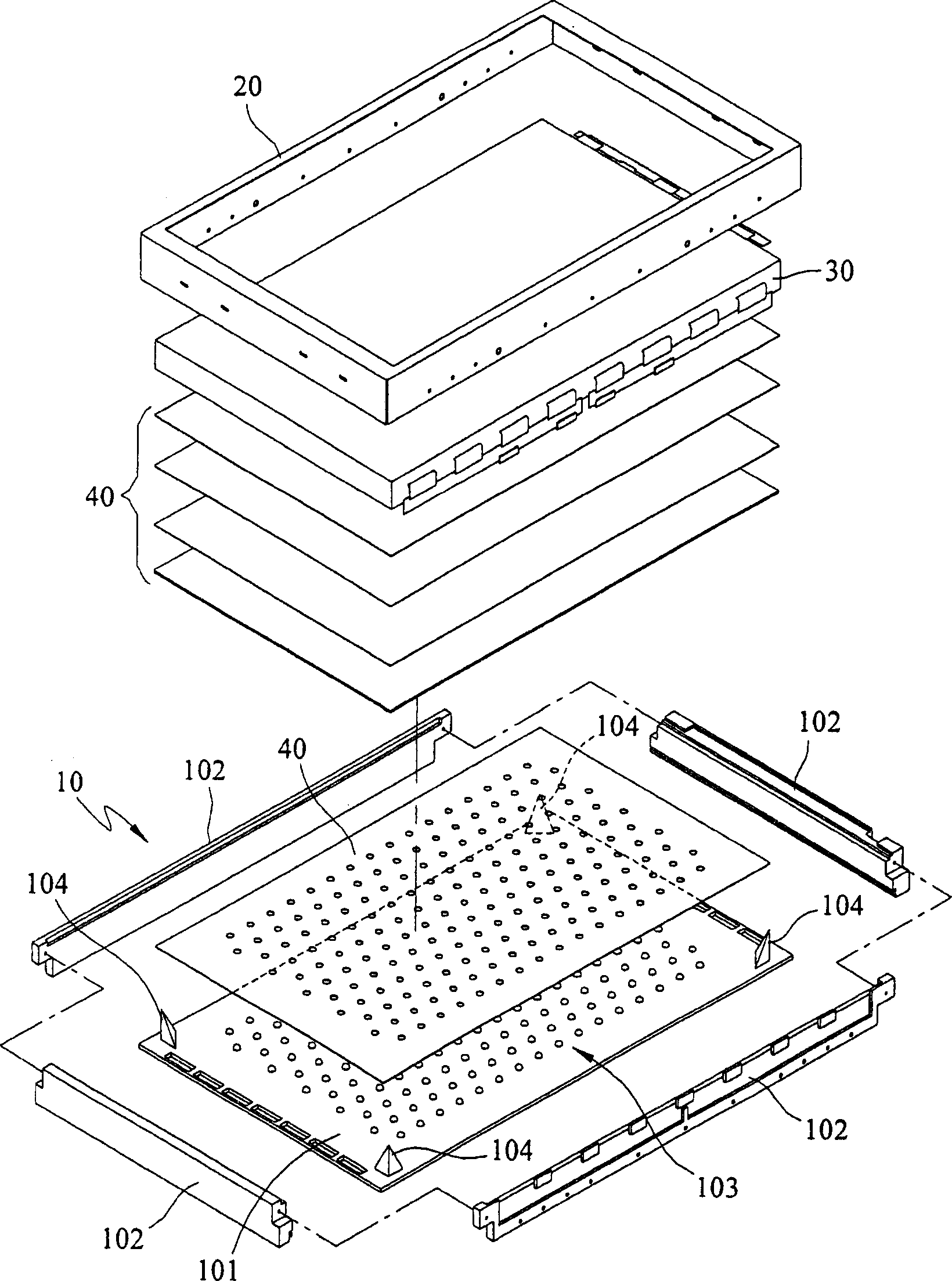

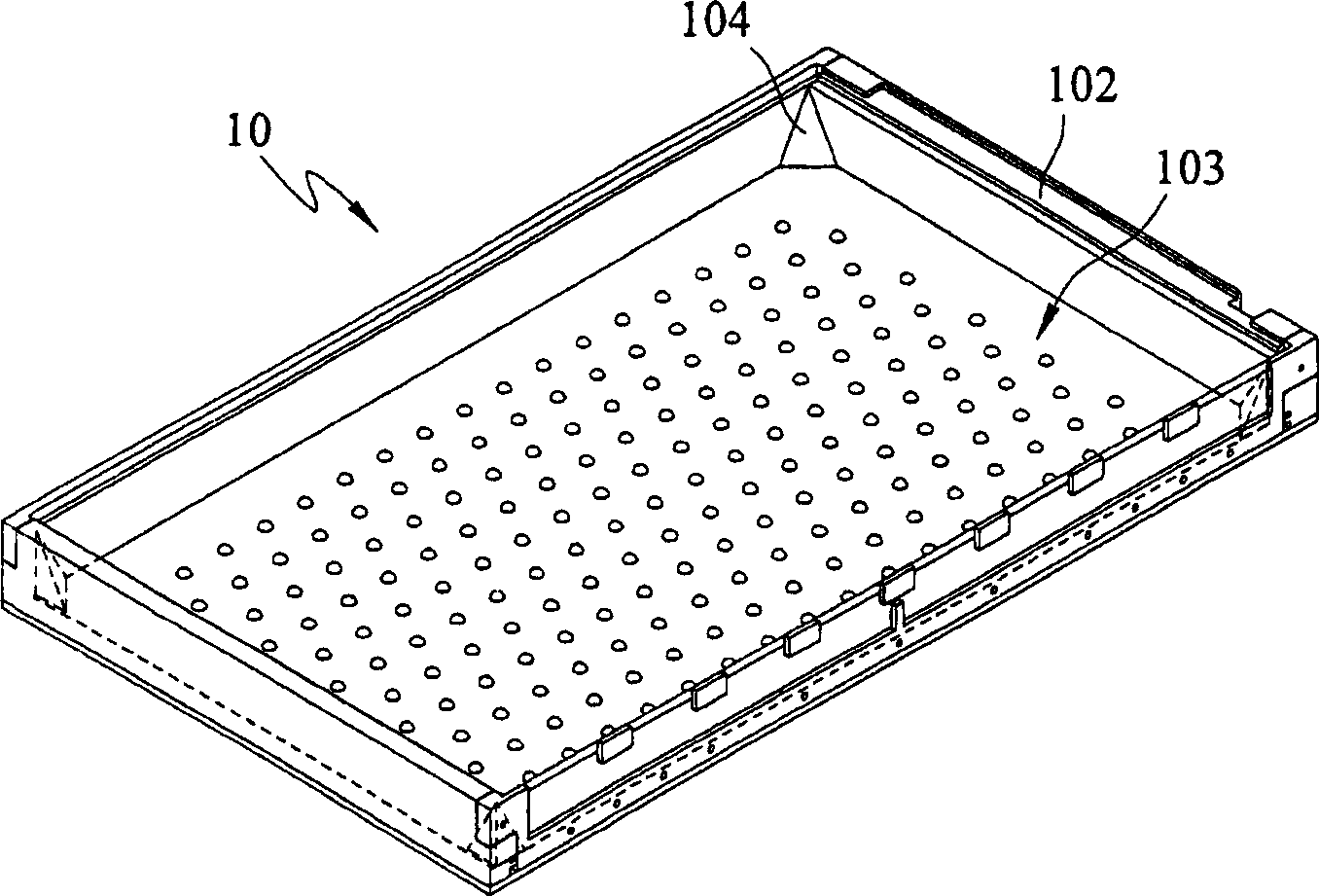

[0032] figure 2 Describe the three-dimensional exploded schematic view of the liquid crystal display of the present invention, the liquid crystal display of the present invention has a liquid crystal panel 30, a front frame 20, is arranged on this liquid crystal panel 30 and fixes it, a backlight module 10, has at least one light source, the best The light source is a light emitting diode array 103, which is arranged on the back plate 101, and a frame body 102, which is arranged on at least two adjacent edge areas of the back plate 101, and defines at least one corner area together with the back plate 101; the liquid crystal A plurality of optical films 40 are arranged between the panel 30 and the backlight module 10 to increase light utilization and efficiency. The plurality of optical films 40 can be diffusion sheets, prism sheets, acrylic optical sheets, brightness enhancement sheets or combinations thereof.

[0033] The corner area of the backplane 101 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com