Method of increasing electric appliance power factor

A reactance and electric welding machine technology, applied in the direction of inductors, variable inductors, transformers/inductor coils/windings/connections, etc., can solve the problem that the power factor will not be improved, the power factor is not high, and the reactance value is not good. Change and other problems, to achieve arc stability, improve power factor, increase the effect of output capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

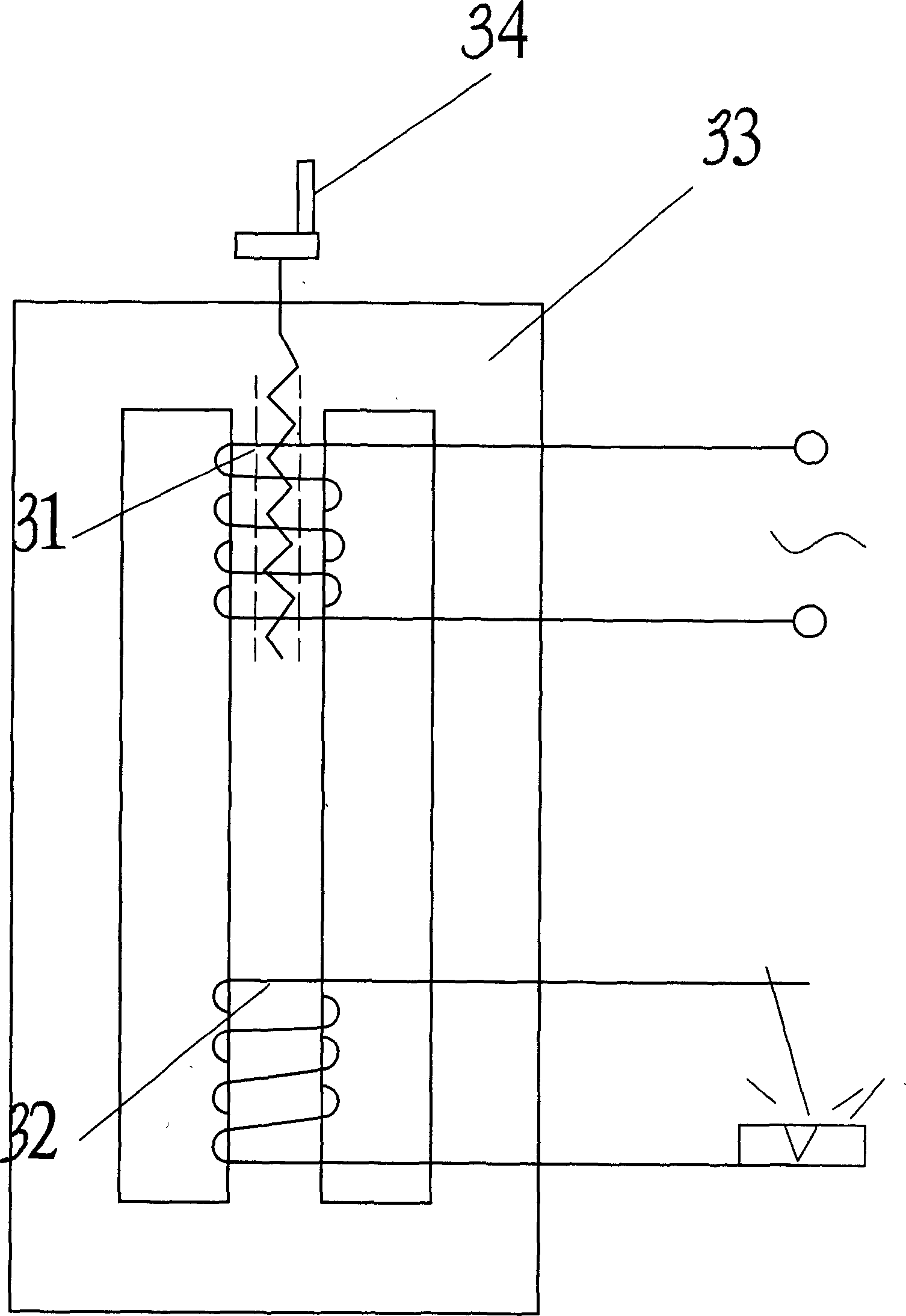

[0043] Embodiment of moving coil AC arc welding machine

[0044] Refer to attached Figure 4 The primary static winding 41 and the secondary static winding 42 of the moving coil AC arc welding machine are independently wound on two different iron core columns of the same iron core 49, and the coils of the reactance dynamic winding 43 are collectively wound on the primary and secondary Outside the two windings, the primary and secondary windings are enclosed in the reactance winding at the same time. The reactance winding is an integral winding. The effective turns of the reactance winding coils wound on the core columns of the primary and secondary windings Exactly the same, the magnetic fluxes generated by the reactance windings on two different iron core columns are equal in size and opposite in direction, and the sum of the induced electromo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com