Manual bisteady-state fast turnover mechanism

A flipping mechanism and bistable technology, applied in the field of manual bistable fast flipping mechanism, can solve the problems of application field limitation and inability to use, and achieve the effects of simple structure, avoiding half-open half-closed state, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

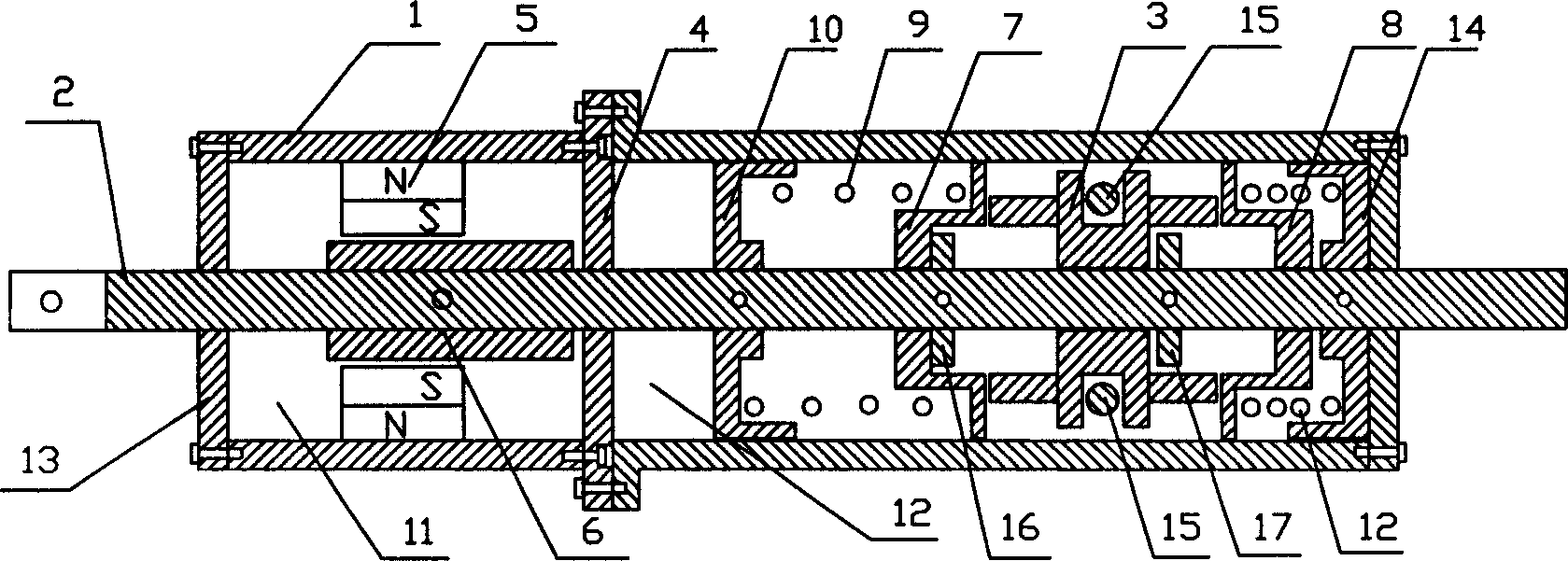

[0014] As shown in the accompanying drawings, the manual bistable quick turning mechanism of the present invention includes a housing 1 and a drive shaft 2 slidably inserted in the housing 1. The housing 1 is cylindrical, with belts at both ends. There is a closed end cover, and there is a partition 4 perpendicular to the drive shaft 2 in the middle of the housing 1. The partition 4 separates the housing 1 into a permanent magnet cavity 11 and a spring cavity 12, and the drive shaft 2 passes through the partition. The board 4 and the end covers on both sides are slidably inserted into the housing 1 . The position in the permanent magnetic chamber 11 on the drive shaft 2 is fixedly equipped with a cylindrical iron core 6, the diameter of the iron core 6 is greater than the drive shaft 2, and the length is less than the width of the permanent magnetic chamber 11, so that it can be moved with the drive shaft 2 The permanent magnet cavity 11 reciprocates; the inner wall of the per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com