Rotary device with sensor and method for forming apparatus for measuring load on rolling bearing unit

A technology of rotating device and rolling bearing, which is applied in the direction of measuring device, rolling contact bearing, bearing assembly, etc., can solve the problems of contamination of the rotation speed detection sensor detection accuracy, damage to the durability of the rolling bearing unit, and reduction of rolling fatigue life, etc. Effects of flux leakage, large manufacturing tolerances, enhanced joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

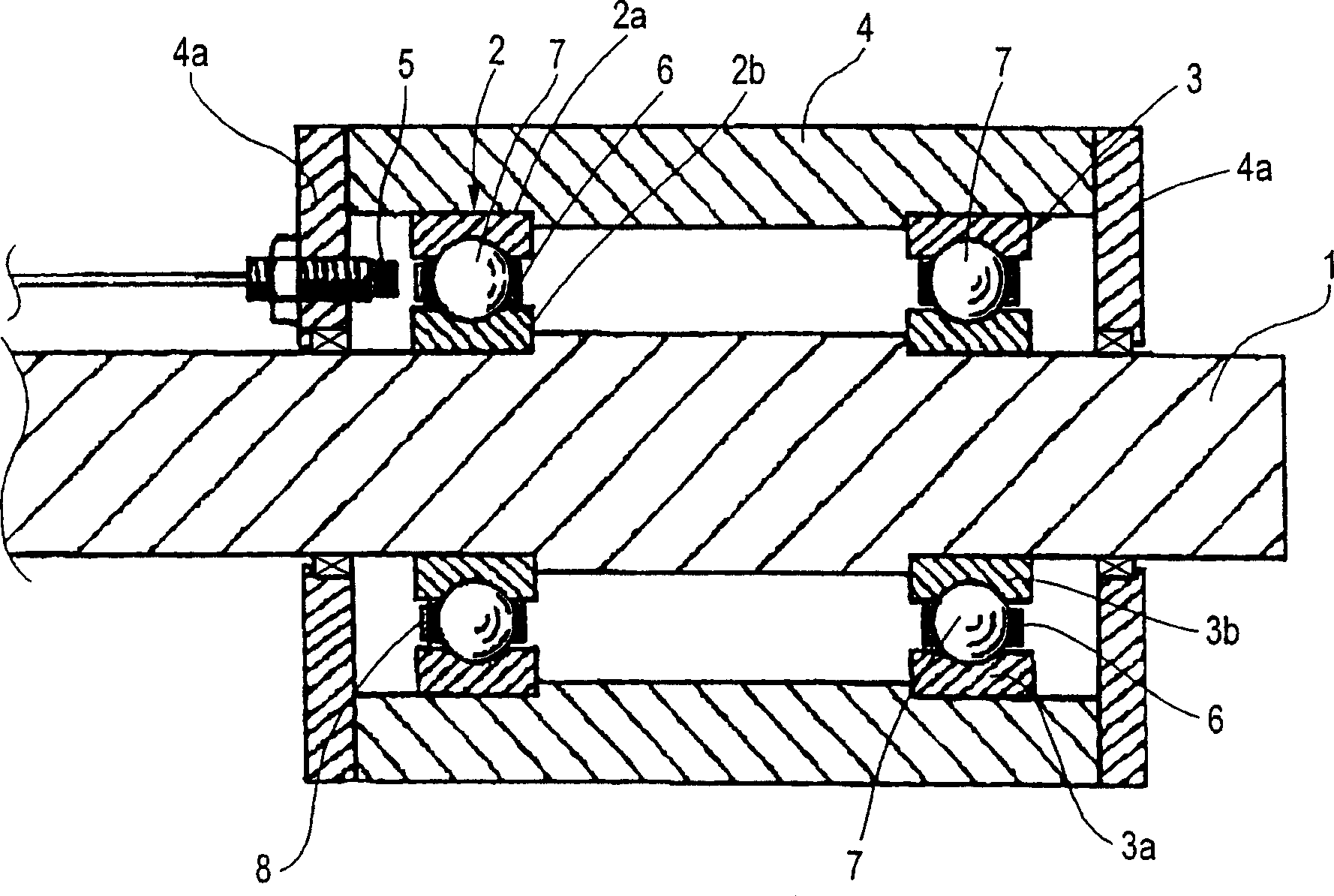

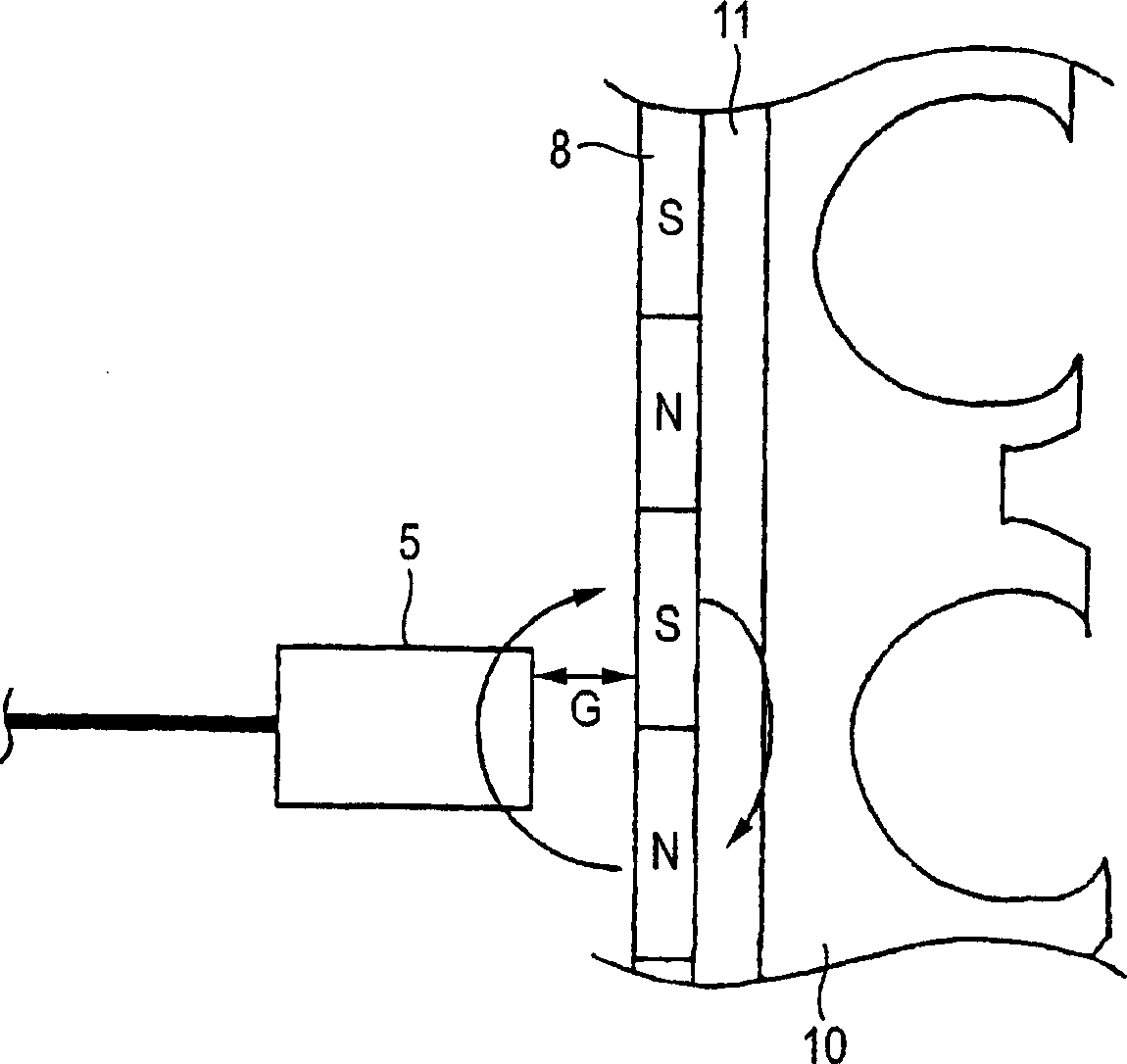

[0097] Example 1 includes a magnet sensor 5 positioned outside the two rows of bearings 2 and 3, and example 3 includes a magnet sensor 5 positioned between the two rows of bearings (two holders 14), such as Figure 4 shown.

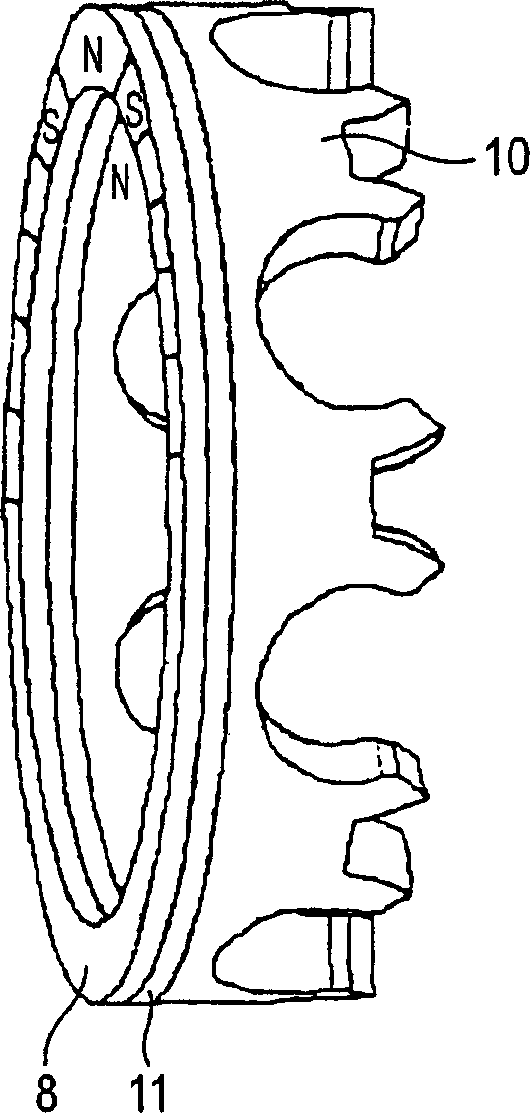

[0098] exist Figure 4Among them, the hub unit used for the wheel bearing is composed of hub wheel 13 and angular contact ball bearing 17. The hub wheel 13 has a radially outward flange 13a on which a wheel, not shown, is mounted, and a hollow shaft 13b having a bearing rotatably supported by an angular contact ball bearing 17 Assembly area. The angular contact ball bearing 17 is of the double row outward type, comprising an inner ring, a separate outer ring 16, a plurality of balls 18a, 18b and two crowned cages 14a, 14b, wherein said inner ring is formed directly on the hollow shaft 13b The inner ring race 15a on the top and the inner ring member 15c fitted on the small-diameter circumference of the hollow shaft 13b with the inner race 15b are forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com