Electrical dedusting installation in high performance

A high-efficiency electrostatic precipitator technology, applied in electrode structure, electrostatic separation, etc., to achieve the effect of enhancing protection awareness, promoting application and industrialization, and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

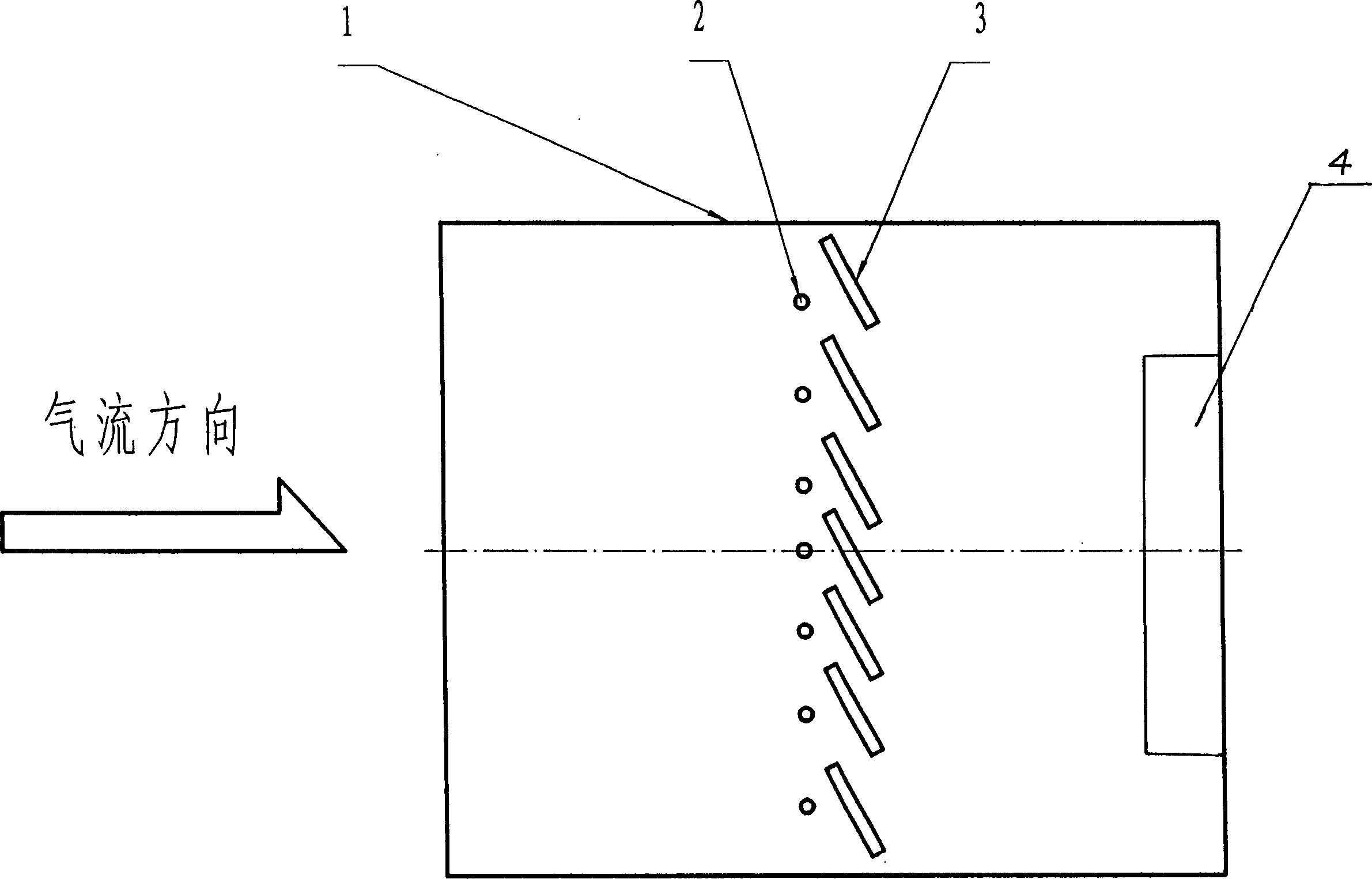

[0012] Such as figure 1 As shown, a standard small electrostatic precipitator is selected, and the steel electrode in the electrostatic precipitator is replaced by nanocrystalline pure iron material with the same appearance size, that is, the dust sink electrode 3, and the insulating material is nano-coated (the structure remains unchanged ).

[0013] The present invention is installed indoors, energized and dedusted when a fire occurs or smoke is present. During use, when the present invention enters between the dust sink pole 3 and the corona pole 2 along the airflow direction, tens of thousands of volts of high-voltage electric field is generated, so that the smoke dust moves toward the dust sink pole 3 and is discharged through the blower fan 4 .

[0014] Wherein: the preparation of nanocrystalline pure iron material can choose common industrial metal materials (such as pure iron), and operate according to the following steps: 1) hot rolling; 2) high temperature annealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com