Hot plates of wall type solar energy collector and manufacturing method

A technology for solar heat collectors and manufacturing methods, applied in the field of solar energy applications, capable of solving problems such as high heat loss, affecting heat exchange efficiency, and low heat collection efficiency, achieving the effects of reducing heat loss, enhancing heat collection efficiency, and improving heat collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

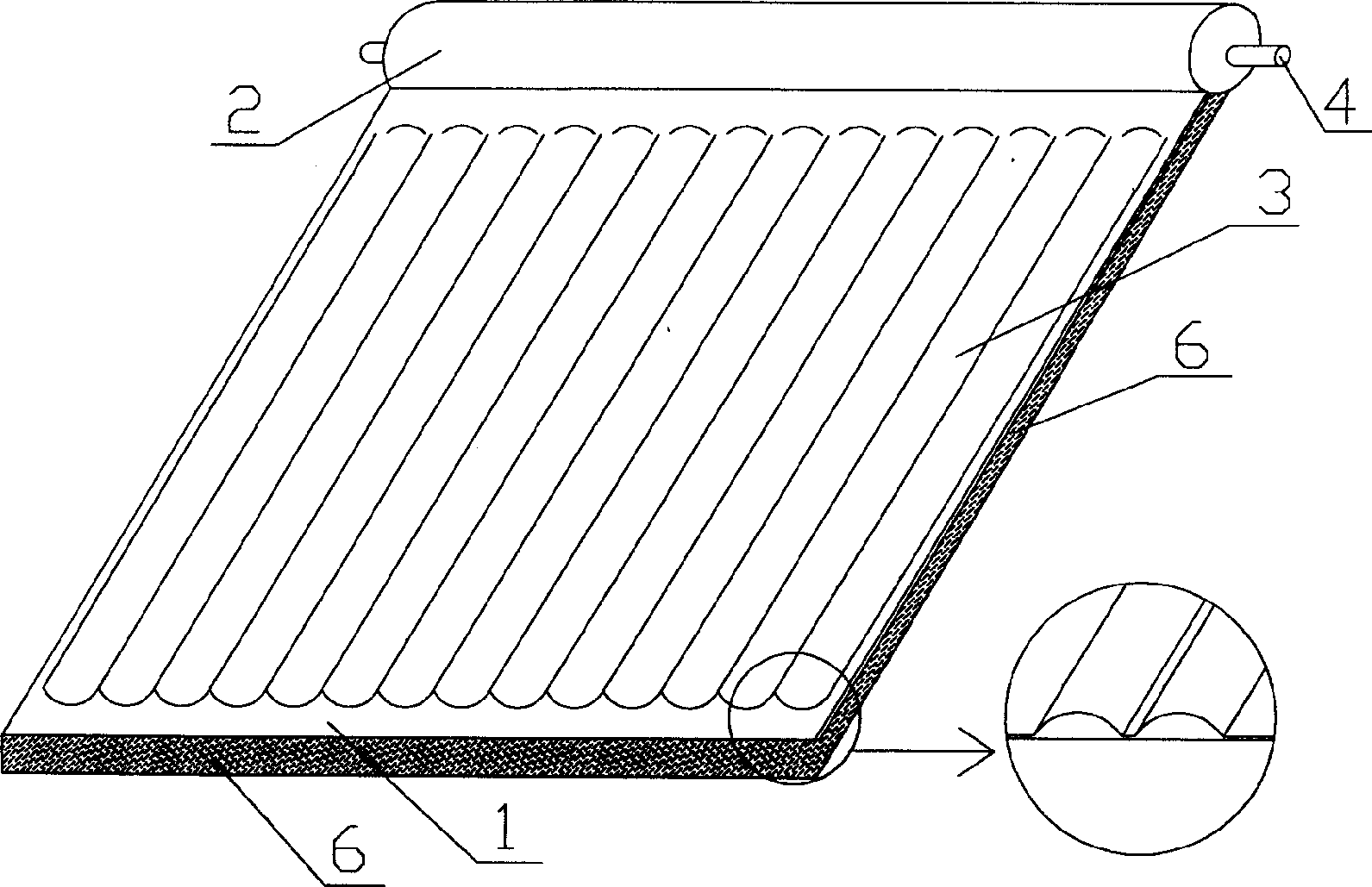

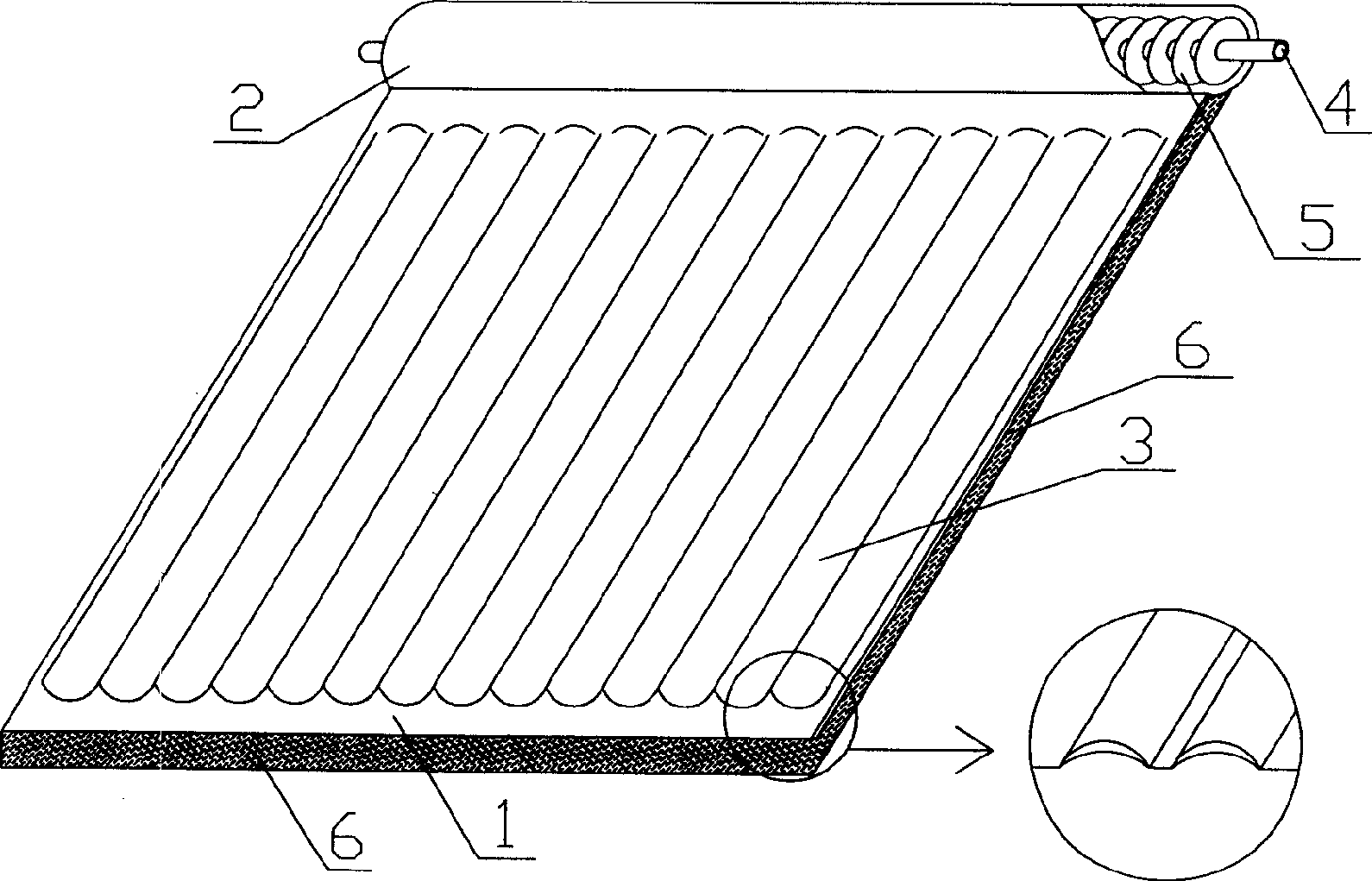

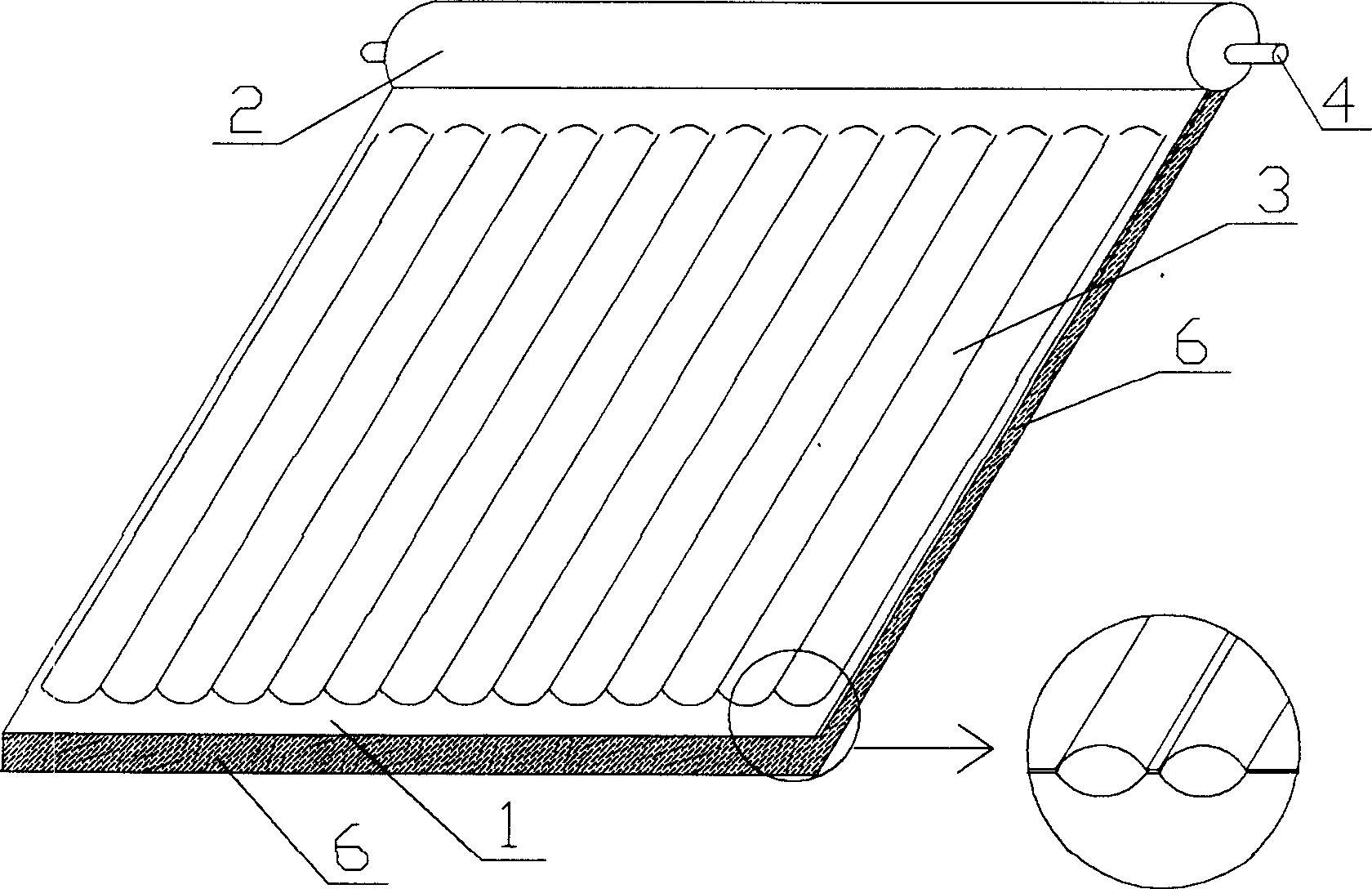

[0027] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. see figure 1 , figure 2 , image 3 Shown in are three implementations of the heat plate in the wall heat plate type solar collector provided by the present invention. It can be seen from the figures that the heat collecting tubes on the heat plate are cavities perpendicular to the bottom formed by the upper and lower surfaces of the metal shell of the heat plate and the welds connecting the two sides, and the heat exchanger is placed above the heat collecting tubes. , is a transverse heat exchange cavity communicated with these heat collection tubes, heat exchange tubes pass through the heat exchanger, and the heat exchange tubes are sealed with the heat exchange cavity at the places where the heat exchange tubes enter and exit the transverse heat exchange cavity. This structure makes the entire heat plate an effective daylighting surface except for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com