Pressure inspection piston and instrument set used therefor

A technology for loading and unloading tools and main bodies, which is applied in the field of pressure-checking plugs, and can solve the problems of reduced test workability, time-consuming, and plug exposure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

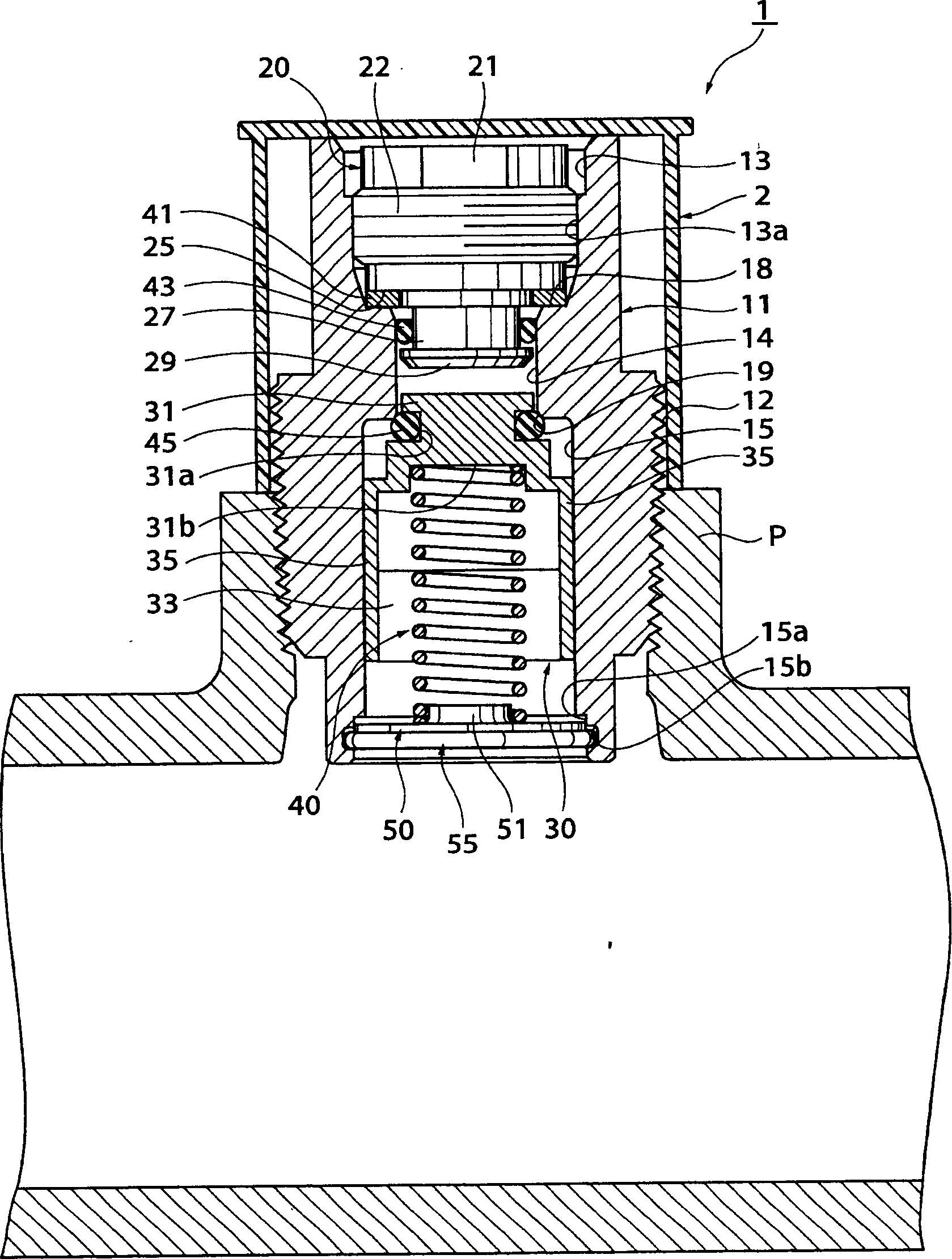

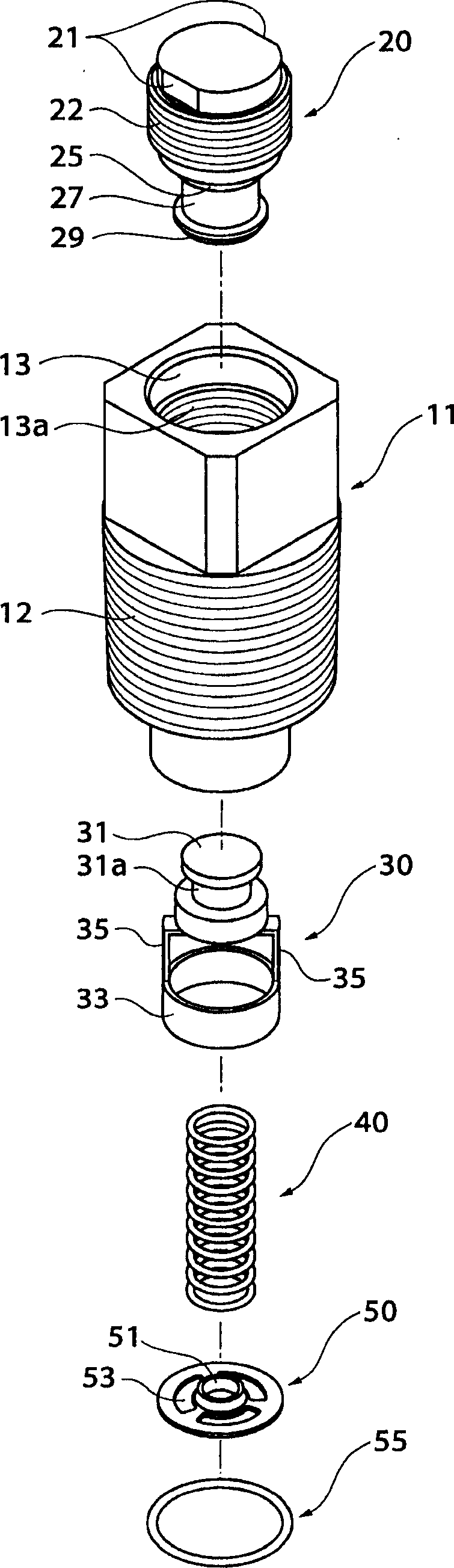

[0049] First, refer to figure 1 as well as figure 2 , the pressure detection plug according to one embodiment of the present invention will be described.

[0050] figure 1 It is a cross-sectional view showing the configuration of a pressure testing plug according to an embodiment of the present invention.

[0051] figure 2 It is an exploded perspective view showing the structure of the pressure detection plug.

[0052] The up, down, left, and right in the present embodiment refer to up, down, left, and right in each figure unless otherwise specified.

[0053]figure 1 as well as figure 2 The pressure testing plug 1 shown has a main body 11 made of copper alloy or the like. The main body 11 has a hollow cylindrical shape. A male screw portion 12 is formed on the lower end side outer peripheral surface of the main body 11 . The male thread portion 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com