Plate for guiding light and backlight module

A backlight module and light guide plate technology, which is applied in optics, optical components, diffraction gratings, etc., can solve the problems of inapplicability to a wide spectral range and low light energy utilization rate of the light guide plate, so as to improve the light energy utilization rate and eliminate Dark band phenomenon, the effect of increasing the diffusion angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

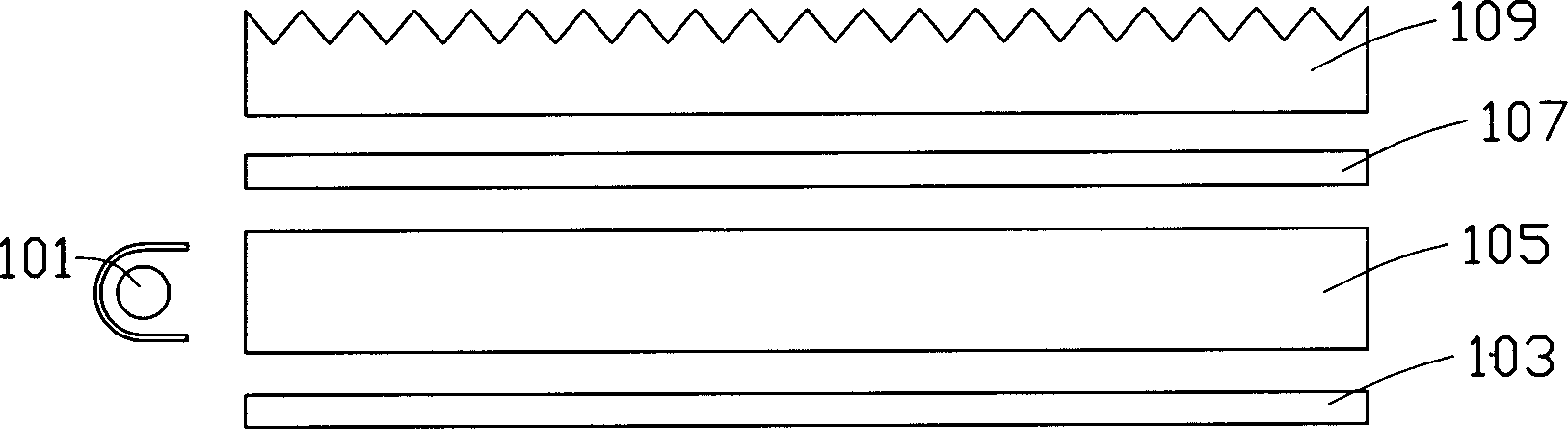

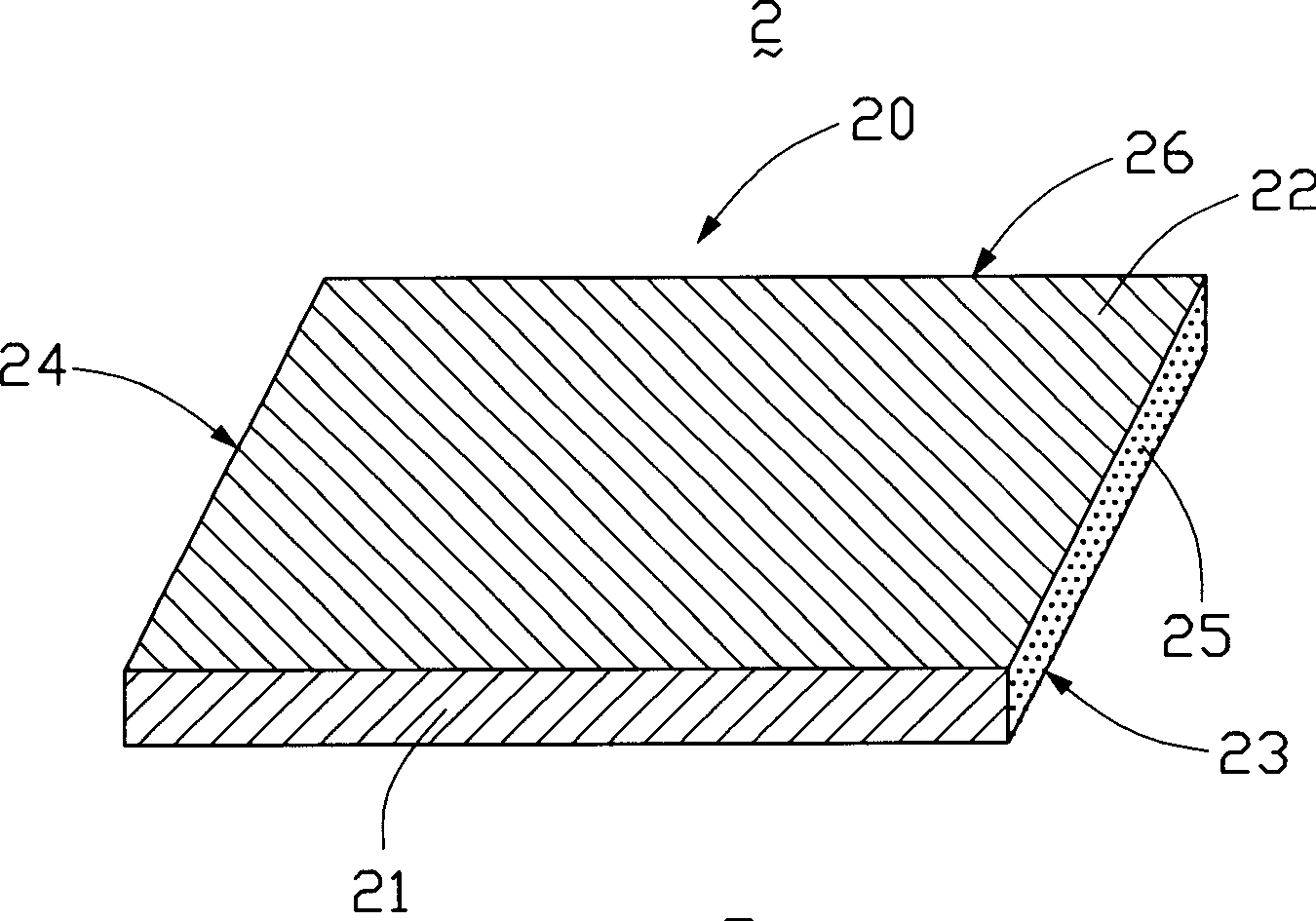

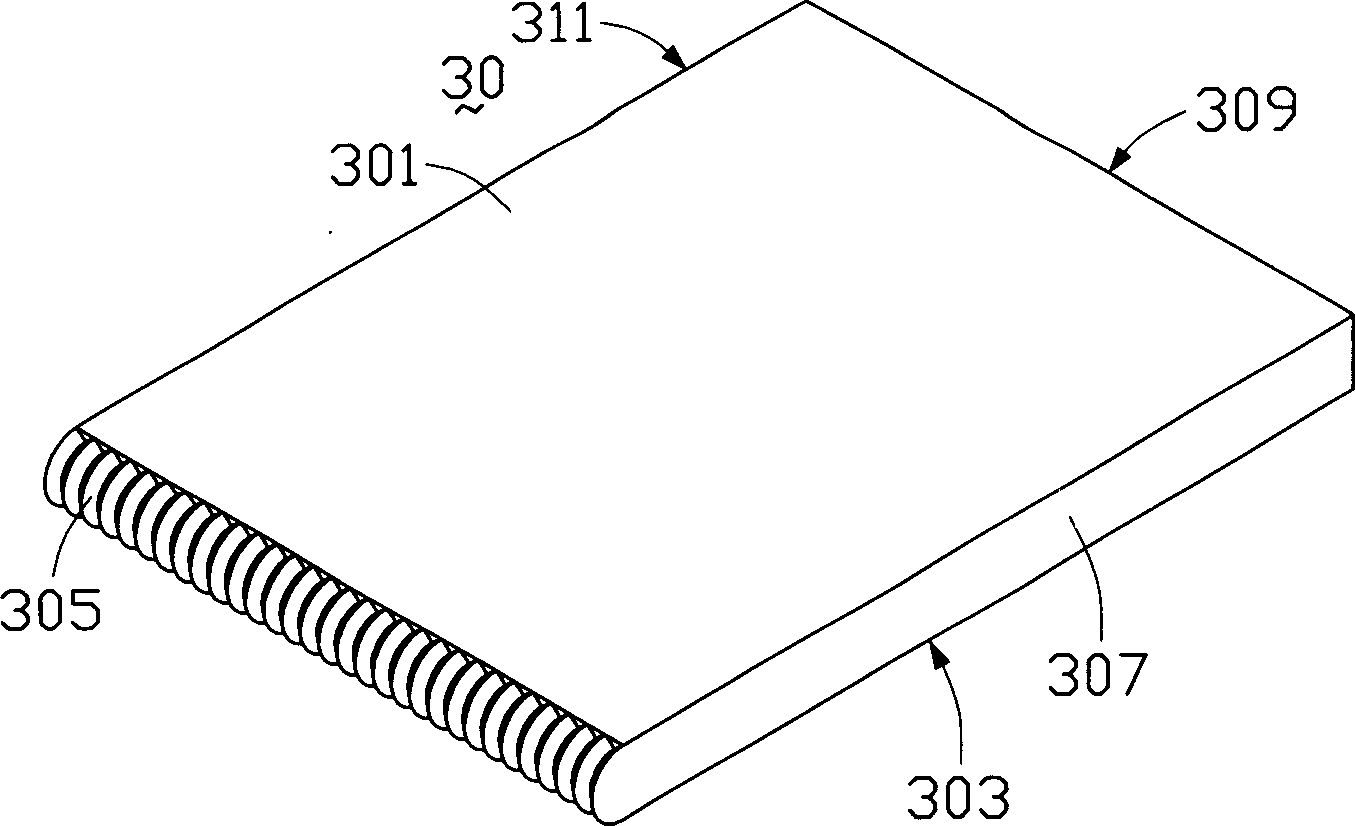

[0017] Please refer to image 3 , Figure 4 and Figure 5 , are respectively a perspective view, a top view and a front view of the light guide plate of the present invention. The light guide plate 30 includes a light incident surface 305 , a light exit surface 301 intersecting the light incident surface 305 , a bottom surface 303 and three side surfaces 307 , 309 , 311 . The light emitted by the light source enters the light guide plate 30 through the light incident surface 305, part of the light directly exits the light exit surface 301, and part of the light is reflected multiple times by the reflector (not shown) arranged near the bottom surface 303, and also exits through the light exit surface 301. The light incident surface 305 is a cylindrical lens structure, and a plurality of sub-wavelength anti-reflection gratings 302 are arranged on the surface, and the sub-wavelength anti-reflection gratings 302 are designed in a V-shaped groove shape.

[0018] The light is dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com