Hydraulic shears

A shearing and hydraulic technology, applied in shearing devices, shearing equipment, underwater operation equipment, etc., can solve the problems of endangering the safety of unmanned remote control submersibles, continuous cutting of wire ropes, inconvenient replacement, etc., achieving light weight, The effect of reducing machining accuracy and working safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

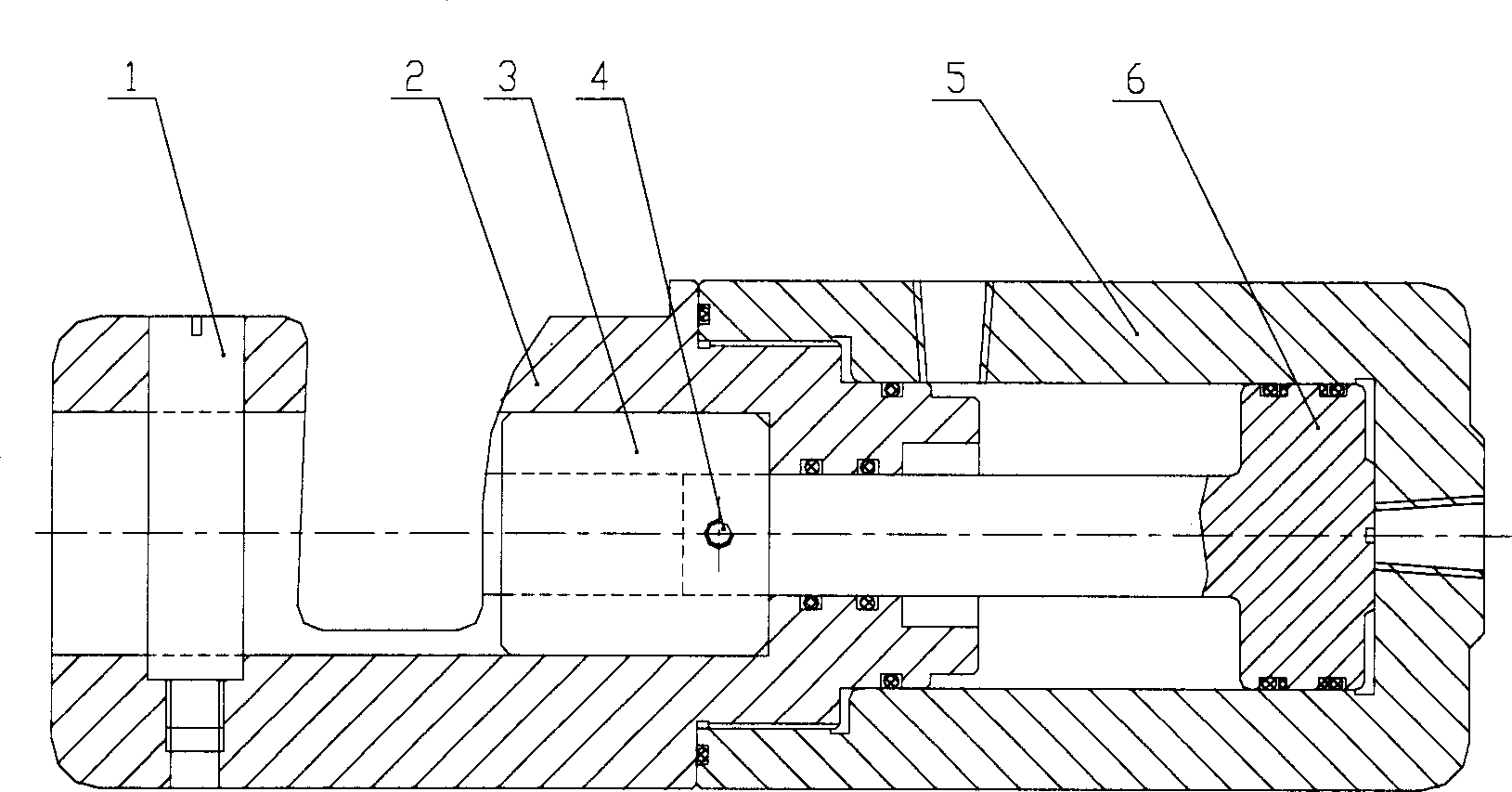

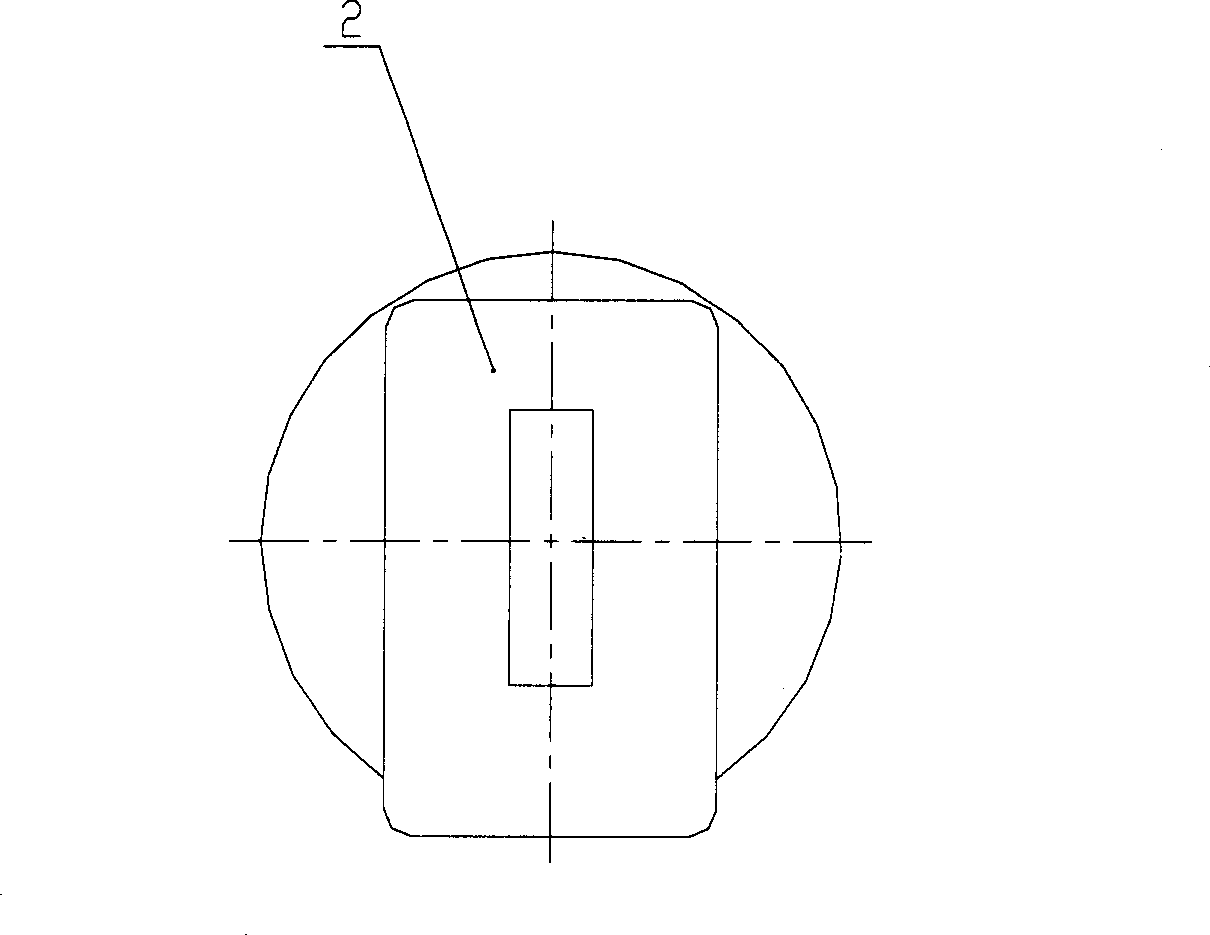

[0014] Such as figure 1 , 2 As shown, the hydraulic shearer of the present invention is structurally mainly composed of a fixed anvil pin 1, a shear head 2, a cutting knife 3, a pull-back cylindrical pin 4, a cylinder body 5, and a piston rod 6, wherein: the shear head 2 is U-shaped One side of the U-shaped structure is a rectangular structure, and there is a grooved guide rail in its horizontal direction (when the cutting knife 3 is placed through the grooved guide rail, the cutting knife 3 is placed in the cavity on the other side of the U shape of the shearing head 2 body structure), there is a cylindrical hole in the vertical direction, and the fixed anvil pin 1 passes through the cylindrical hole and is connected to the U-shaped bottom edge through threads; the other side of the U-shaped is a cylindrical structure, which is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com