Method and device for thermolysis preparing liquid fuel from steam explosion stalk fermented residue

A technology for steam-exploding straw and residues, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry, and can solve the problems of intensified secondary reactions of pyrolysis steam, low conversion rate of volatile matter, serious secondary reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: wheat straw

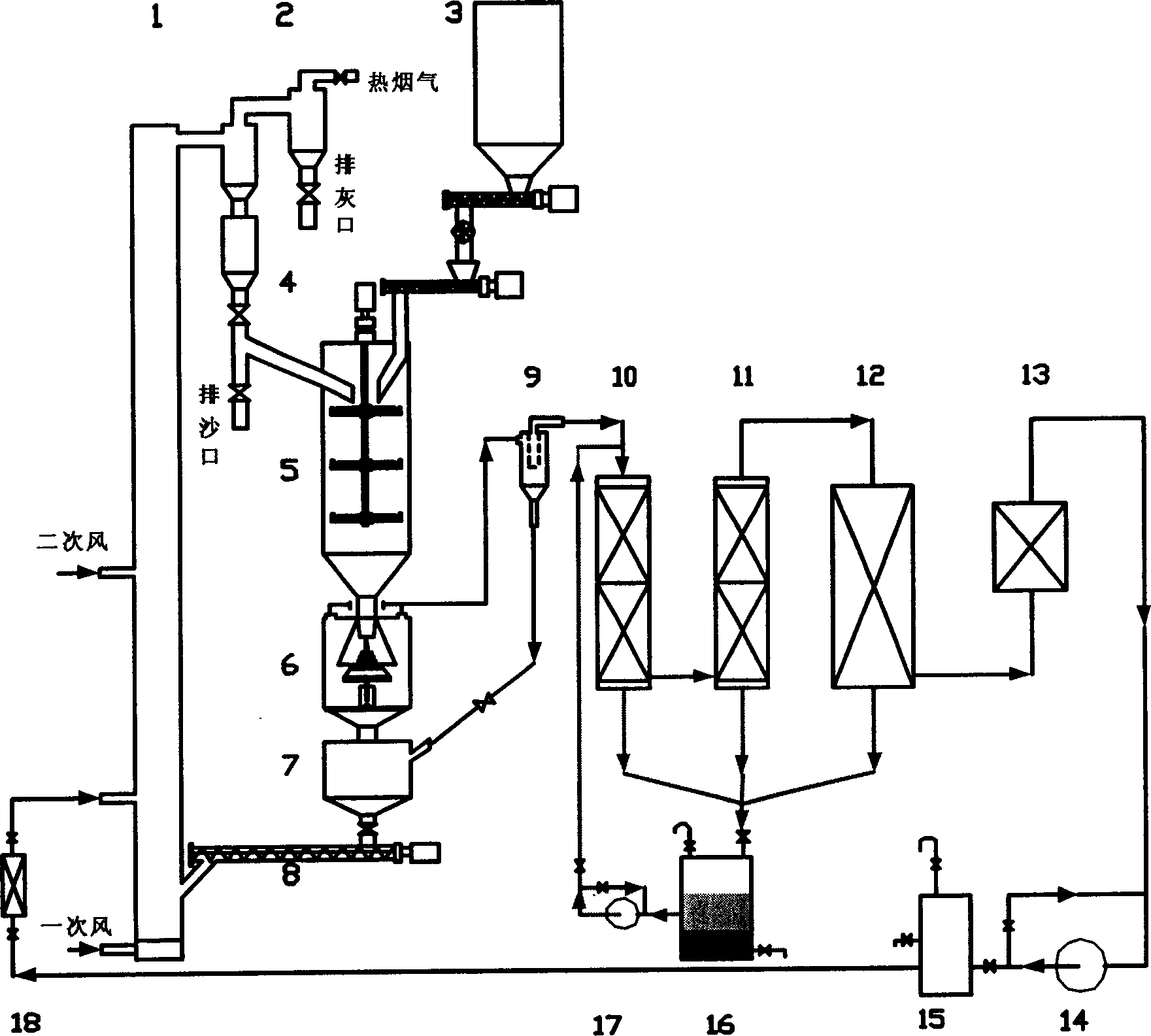

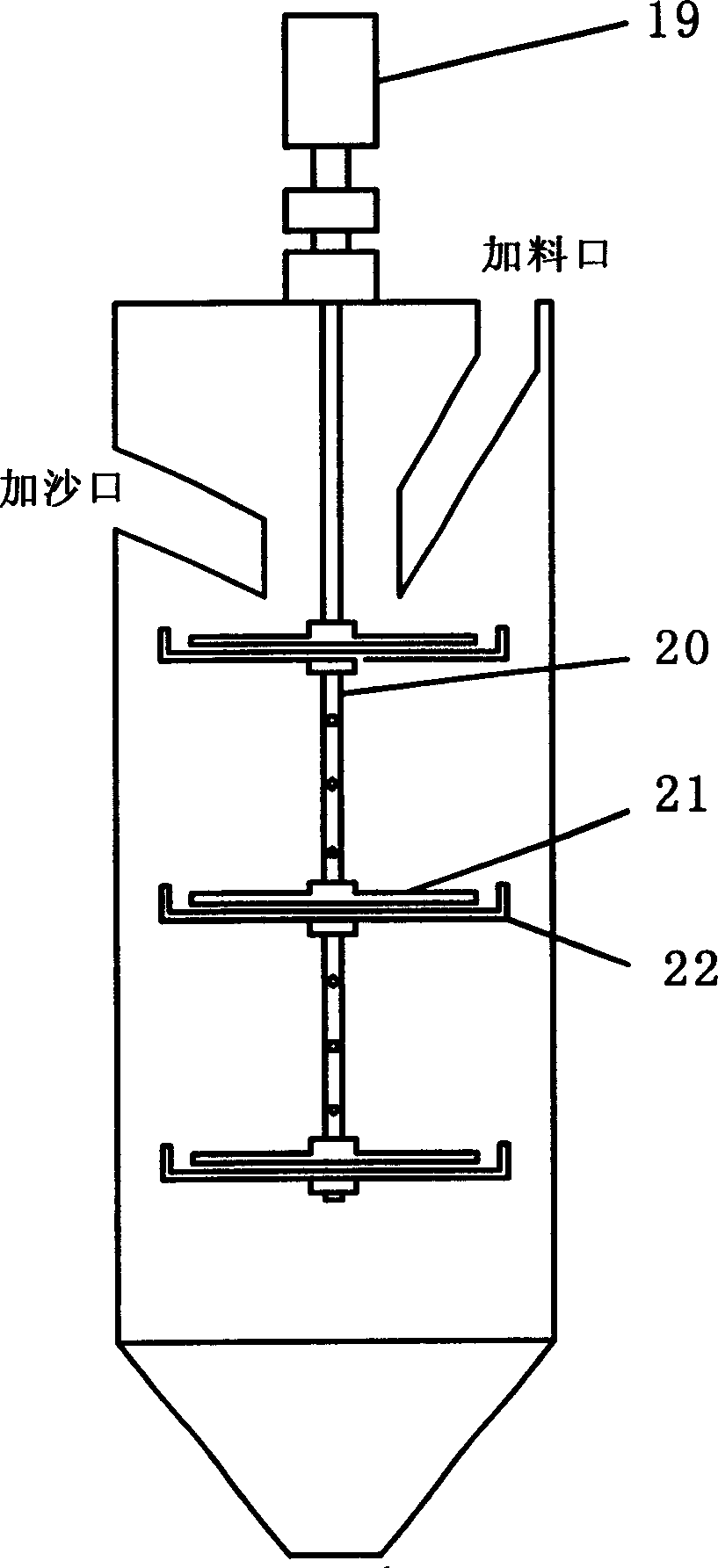

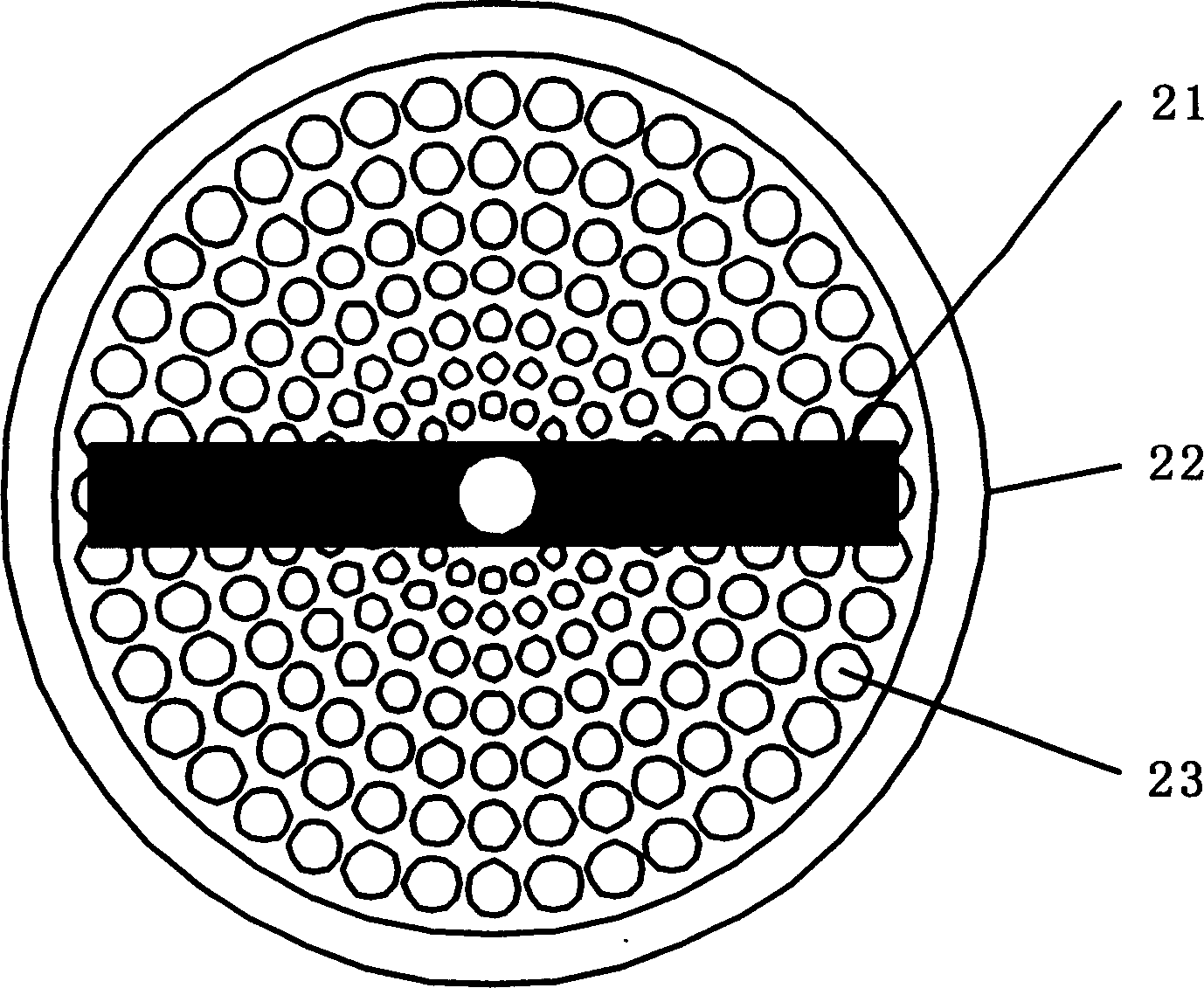

[0058]After the wheat straw is steam-exploded and fermented to remove hemicellulose and part of the cellulose, the remaining residues with high C and H values are dried and pulverized, then added to the straw silo, and fed by a two-stage screw feeding device. Rotary sieve plate pyrolyzer, and heat transfer and pyrolysis on the rotating sieve plate mixed with hot sand from the hot sand bin, unpyrolyzed wheat straw and semi-coke, hot sand is transferred to the next rotating sieve plate step by step, heat transfer, Pyrolysis, the semi-coke and pyrolysis steam formed together with the hot sand enter the gas-solid rapid separator for separation, the separated pyrolysis steam enters the cyclone filter for further coke removal, and the clean pyrolysis steam enters Tubes—quickly condensed in the double-wall sprayer, the non-condensable pyrolysis steam is further condensed and collected by the cryocooler and electrostatic collector, and the pyrolysi...

Embodiment 2

[0060] Example 2: corn stalks

[0061] Corn stalks are steam-exploded and fermented to remove hemicellulose and part of the cellulose, and the remaining residues with high C and H values are dried and pulverized, then added to the straw silo, and fed by a two-stage screw feeding device. into the rotary sieve plate pyrolyzer, and mixed with the hot sand from the hot sand bin on the rotary sieve plate for heat transfer and pyrolysis. Heat and pyrolysis, the semi-coke and pyrolysis steam formed together with the hot sand enter the gas-solid rapid separator for separation, and the separated pyrolysis steam enters the cyclone filter for further removal of coke ash, clean pyrolysis steam Then enter the tube-double-wall sprayer to condense quickly, and the non-condensable pyrolysis steam will further condense and collect the pyrolysis liquid through the cryocooler and electrostatic collector, and collect the pyrolysis liquid stored in the storage tank, that is, the obtained of liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com