System and method for automatic acquisition and correspondence of production data

A production line data and data collection technology, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., can solve the problems of the combination of production line system control, low system security, and poor automatic error correction capability. , to achieve the effect of strong automatic error correction ability, high data collection rate and guaranteed accuracy

Inactive Publication Date: 2011-01-05

东方惠科防伪技术有限责任公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the problems of low data collection rate, poor automatic error correction ability, low system security and inability to be well combined with production line system control in the current production line data collection and corresponding systems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an automatic production line data gathering and corresponding system and method, which comprises the following parts: digital loading device, data gathering device, data corresponding and control device, data corresponding unit and database, wherein the digital loading device contains electric eye and labeler, which controls the labeler to attach the bar code mark on the correct position when the electric eye detects the passing production; the data gathering device displays scanner with group scanning function, which scans each group of bar code mark simultaneously and sends the data to the database; the data corresponding and control device contains control unit to control digital loading, data gathering and data storing operation; the data corresponding unit establishes data corresponding relationship; the database connects the data gathering device, data corresponding and control device to store the gathered data. The invention is fit for high-speed production line.

Description

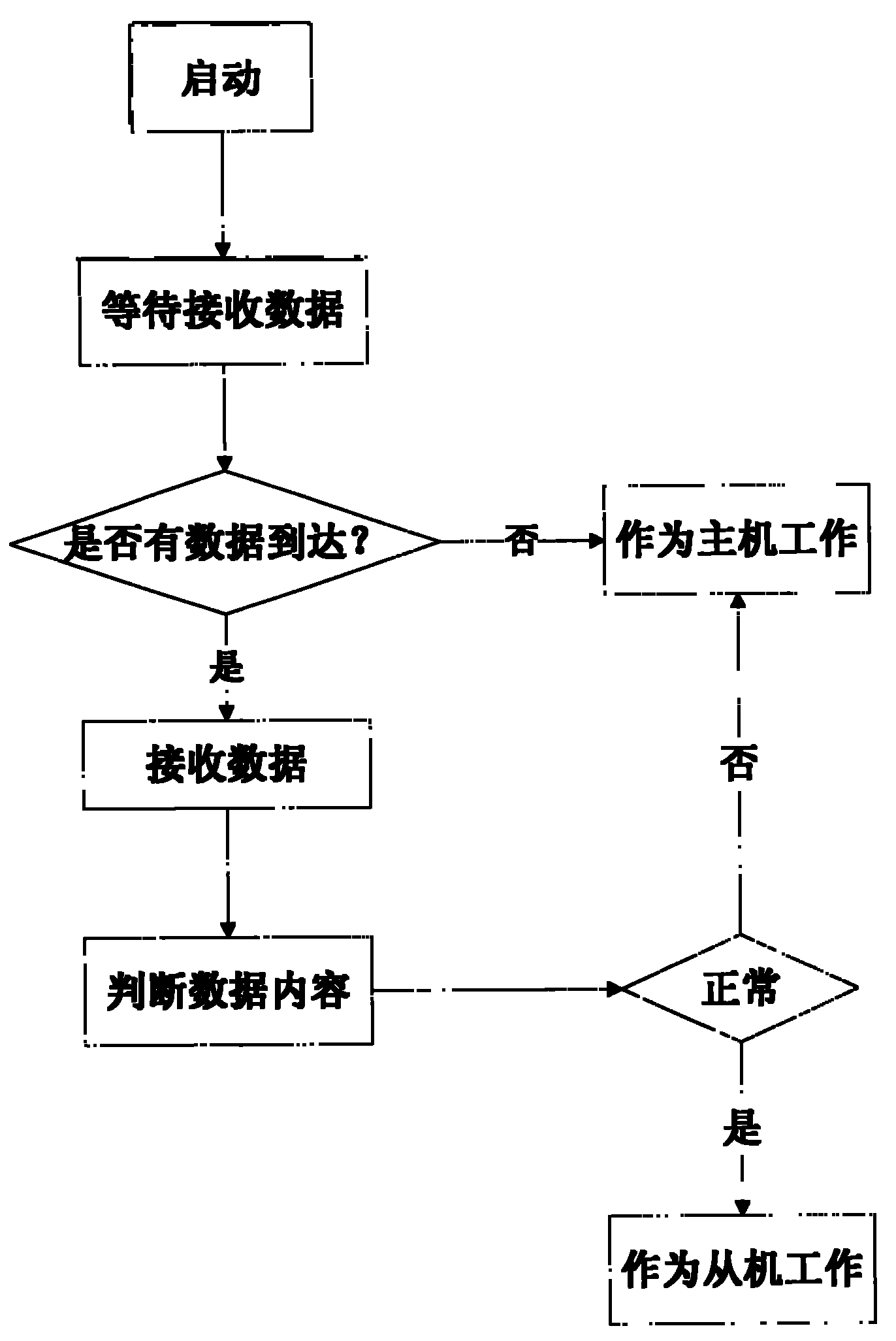

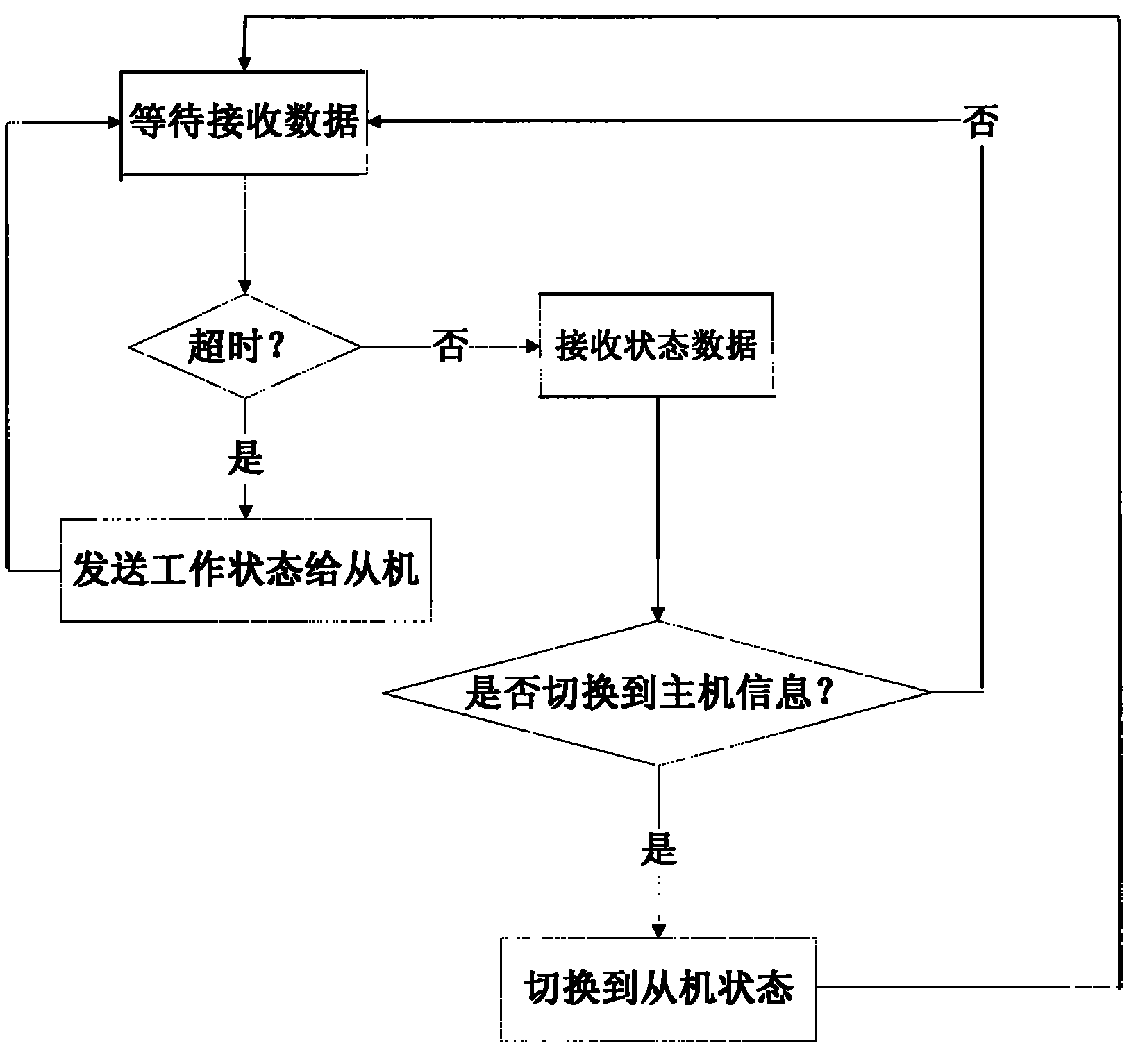

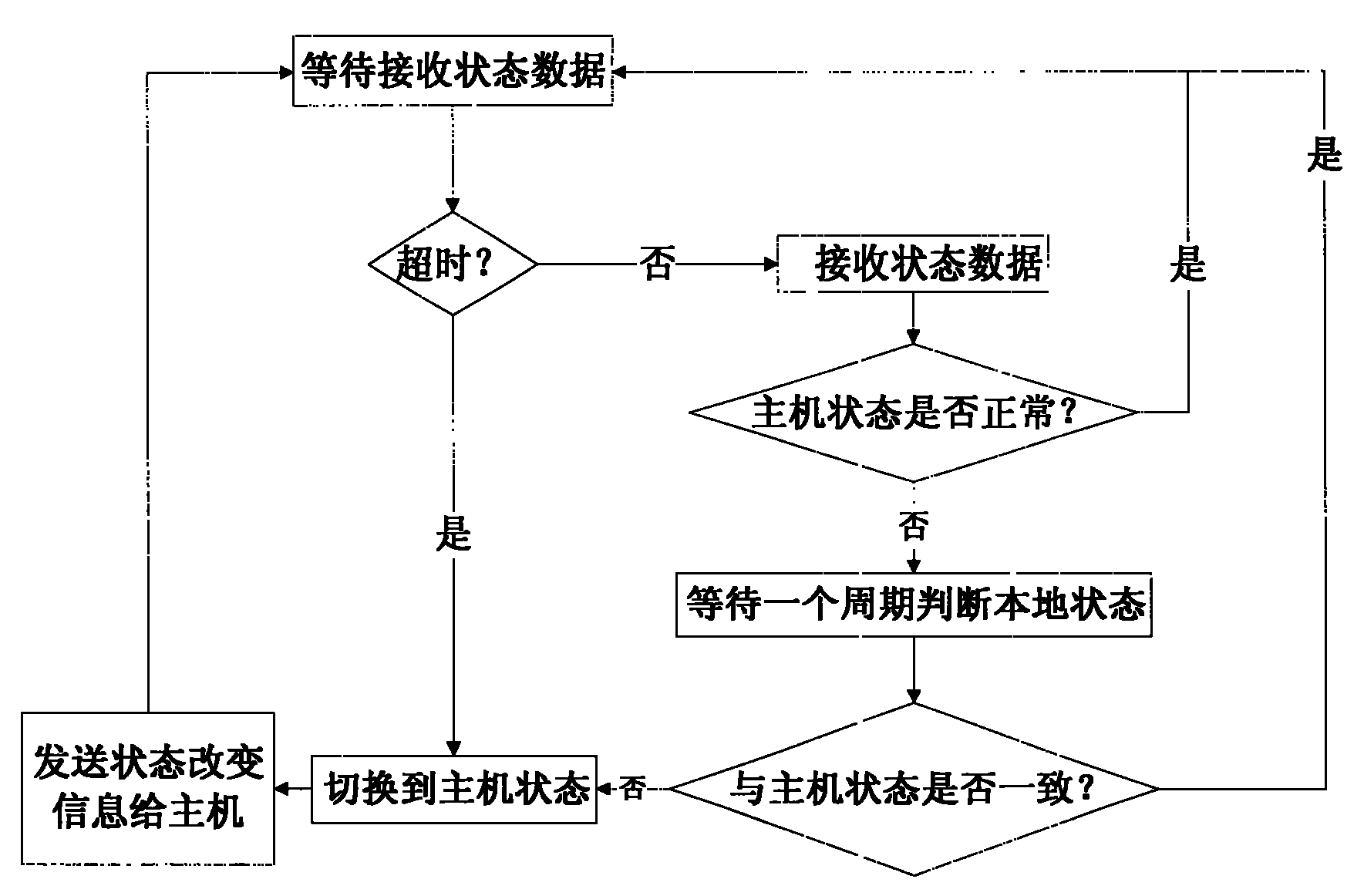

Production line data automatic collection and corresponding system and method technical field The invention relates to a production line data automatic collection and corresponding system and method, belonging to the production line data automatic collection and corresponding technical field. Background technique Today, with the rapid development of information technology, for the manufacturing industry, only by realizing the digitalization of products and realizing the corresponding digitalization of large and small packaging, can the digital anti-counterfeiting of products and the control of sales channels be realized. Realizing product digitalization and data acquisition and correspondence requires comprehensive computer security technology, automatic identification technology, database technology, and industrial network and control technology. At present, these aspects have mature technologies and related equipment. How to integrate these mature technologies and equipme...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G05B19/418G05B23/00

CPCY02P90/02

Inventor 王恒彬卢钢

Owner 东方惠科防伪技术有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com