Preparation method of ferrite for microwave production and die arrangement thereof

A technology of ferrite and microwave oven, which is applied in the field of preparation of ferrite for microwave oven, can solve the problems of poor flexibility, not high enough, affecting the performance of microwave oven, etc., and achieves the effect of improving magnetic field and qualification rate and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

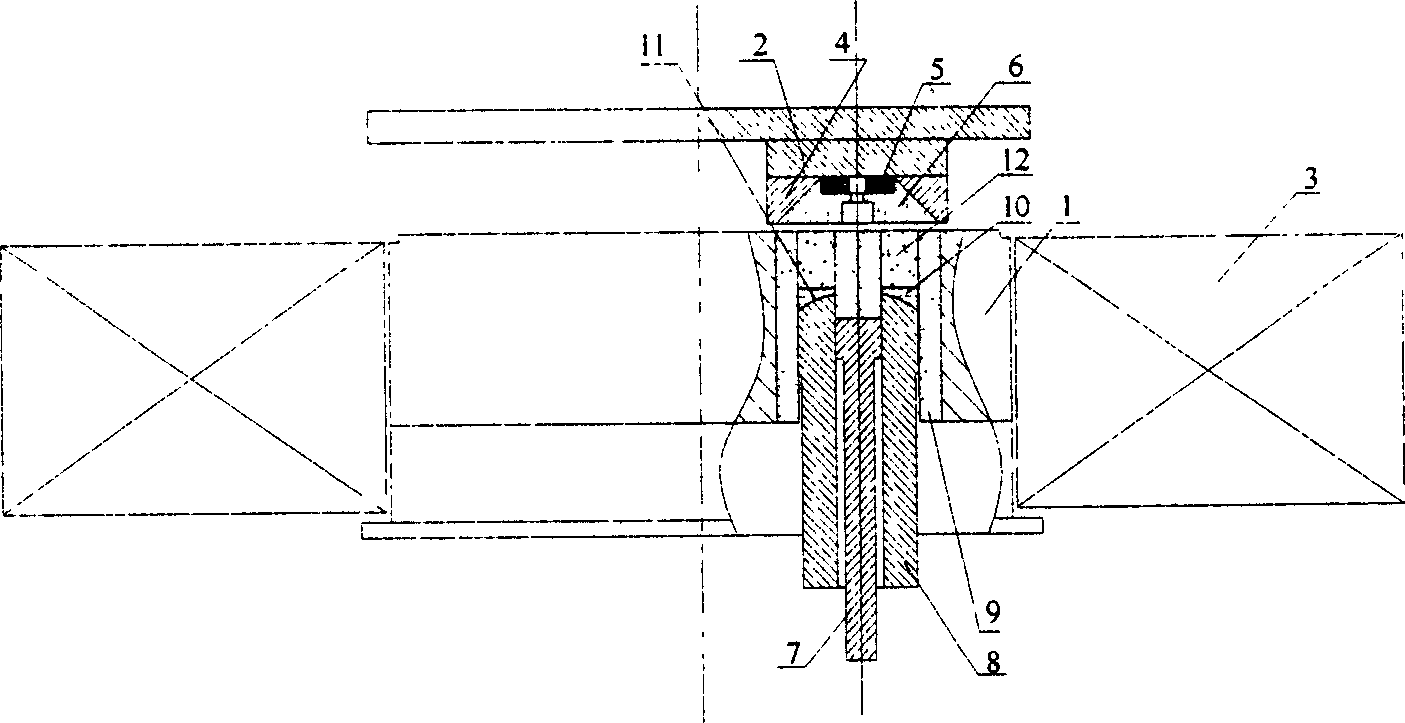

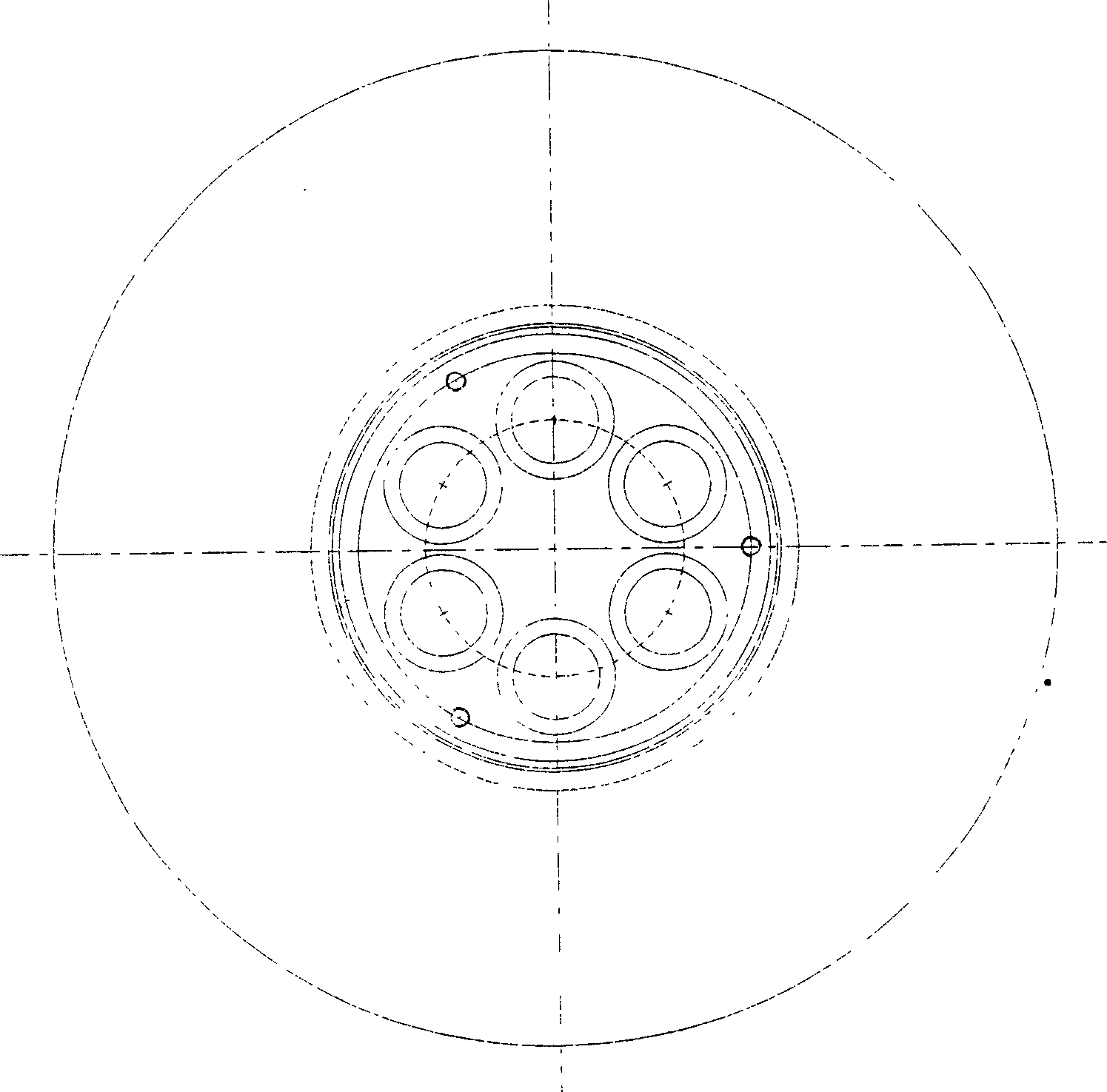

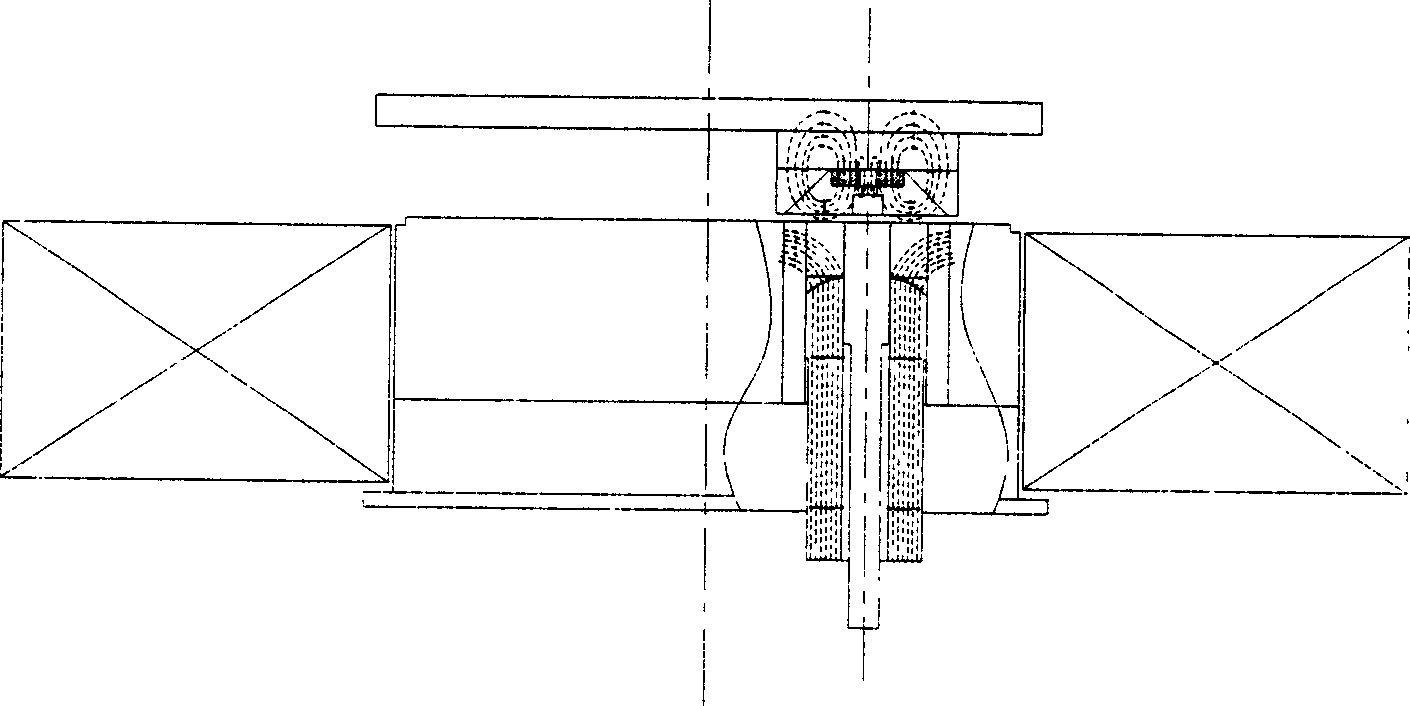

[0021] figure 1 and figure 2 shows the concrete structure of the present invention, by figure 1 and figure 2 It can be seen that the magnetic steel mold for producing ferrite for microwave ovens comprises a die 1, an upper die 2, a coil 3, a water-absorbing plate 4, a NdFeB permanent magnet 5, a non-magnetic block 6, a mandrel 7, a punch 8, Cemented carbide cavity wall 9, non-magnetic block 10; the upper mold 2 is located on the upper side of the mould, the die 1, mandrel 7, punch 8 are opposite to the upper mold 2 and are arranged on the lower side of the mould, the mandrel 7 , The punch 8 extends into the through hole of the die 1, the cemented carbide cavity wall 9 and the die 1 are integrated through thermal expansion treatment, the punch 8 and the cemented carbide cavity wall 9 are fitted and connected, and the mandrel 7 extends into the through hole of punch 8; coil 3 is arranged on the outside of die 1; The non-magnetic block 6 is located on the outside of the NdF...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com