Copper based precipitation hardening alloy

A precipitation hardening and alloying technology, which is applied in the field of copper-based precipitation hardenable alloys, can solve the problems of poor copper conductivity and copper softness, and achieve the effect of improving conductivity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

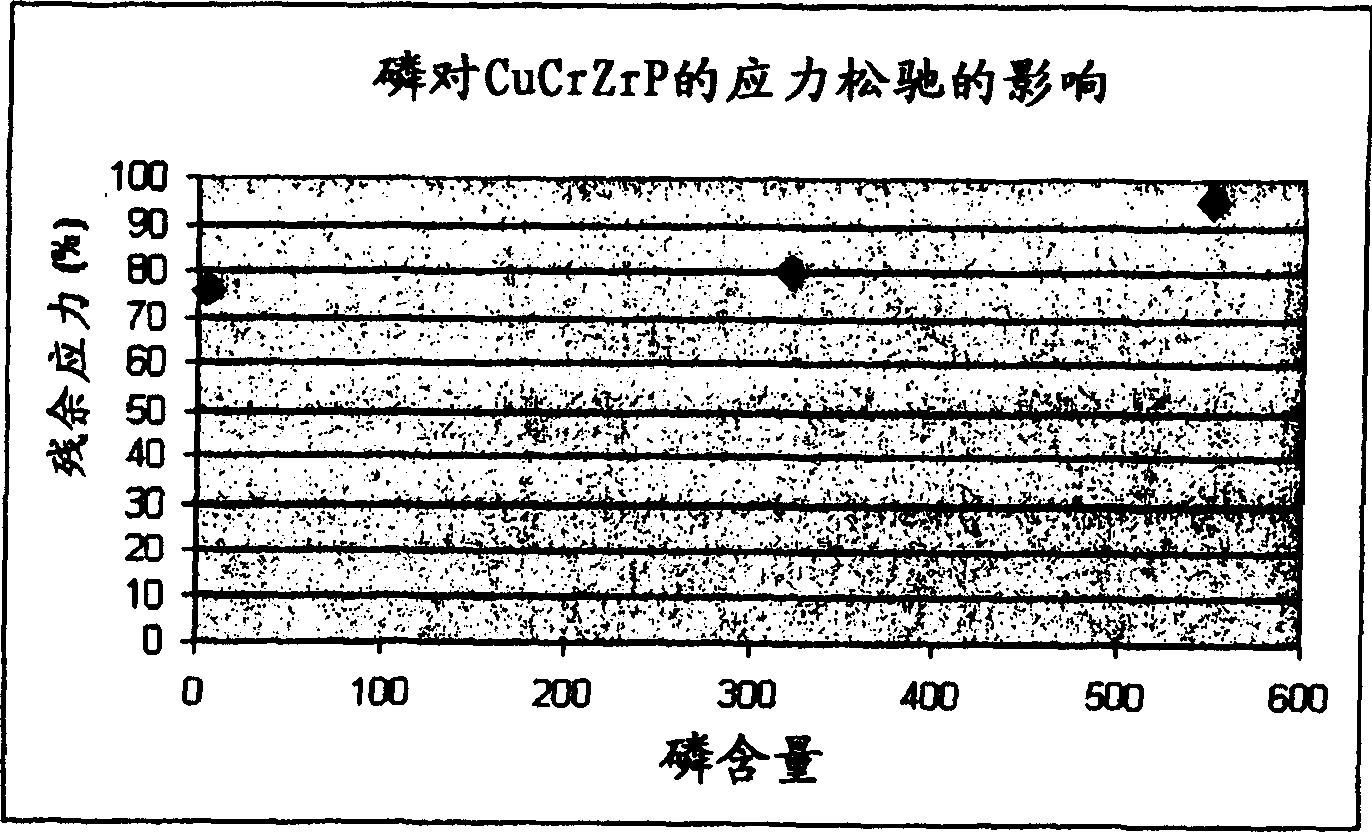

[0013] The addition of phosphorus up to 500 ppm to Cu-based precipitation hardenable alloys containing Cr, Zr and Ti has a direct effect on the electrical conductivity of the alloy. The addition of P can reduce the solubility of alloying elements Cr, Zr or Ti in the final crystal structure of face centered cubic Cu. For example Cr forms thermally stable phosphides such as Cr 3 P and CrP 4 , but does not form complex phosphides with copper. One reason is that the final crystal structure of Cr is body centered cubic (bcc) instead of face centered cubic (fcc) of Cu.

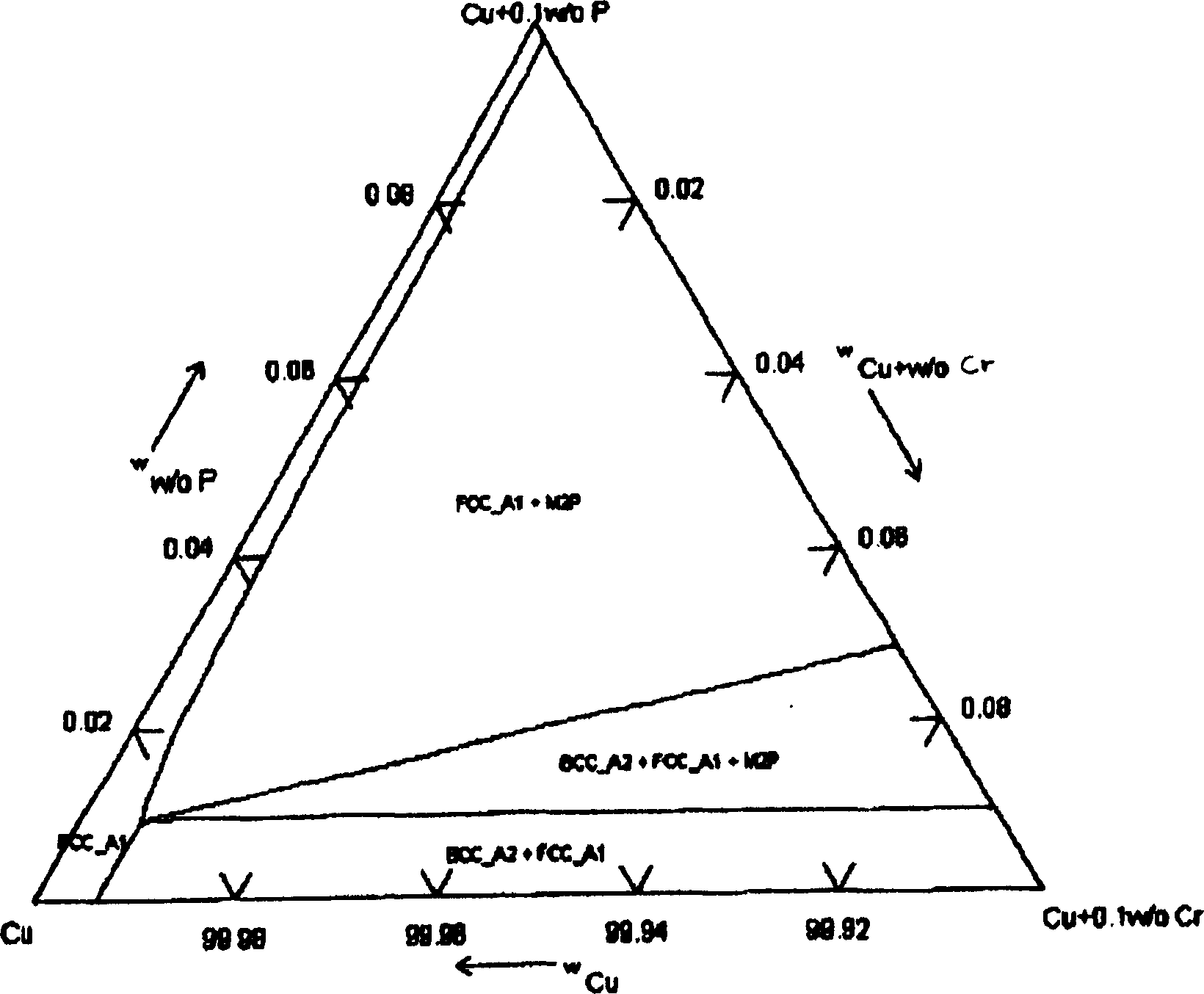

[0014] In the presence of P, the solubility of Cr in Cu is as figure 1 As shown, it is referenced from Villars P., Prince A., Okamoto H., Ternary Alloy Phase Diagrams Handbook (Thernary Alloy Phase Diagrams), Vol7&8, AsM International, Metals Park (OH), 1998. figure 1 Indicates the additive Cu-Cr-P ternary alloy at 600 °C near the copper endpoint, "additive" means that the ternary interaction is neglected, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com