Wood floor with multilayer impregnated paper structure and its making process

A multi-layer structure, impregnated paper technology, applied in the direction of wood layered products, layered products, building structures, etc., can solve the problems of coarse particles, affecting the aesthetics of the floor, uneven sticking, etc., to achieve good stability and ease of use. Clean, not easy to deform the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

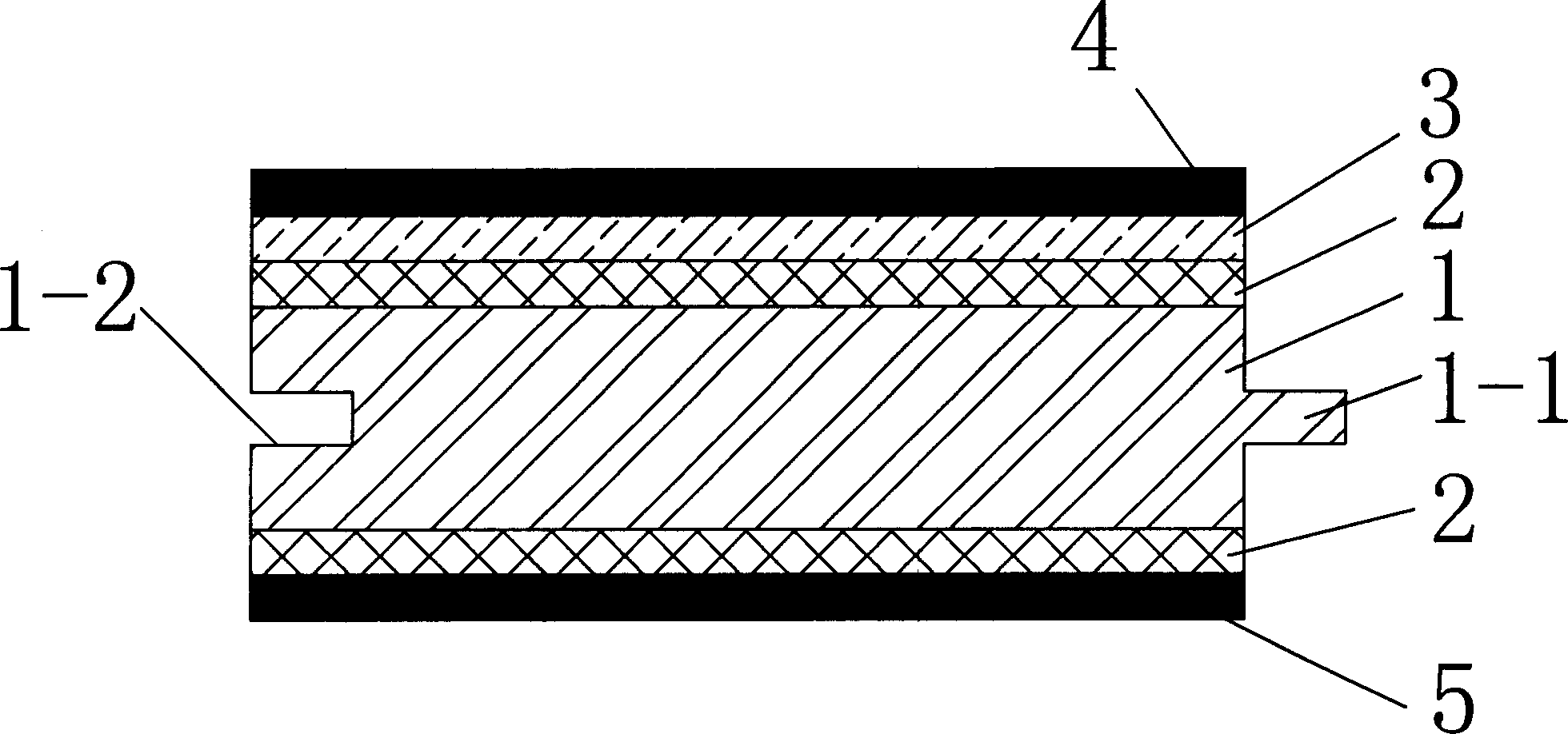

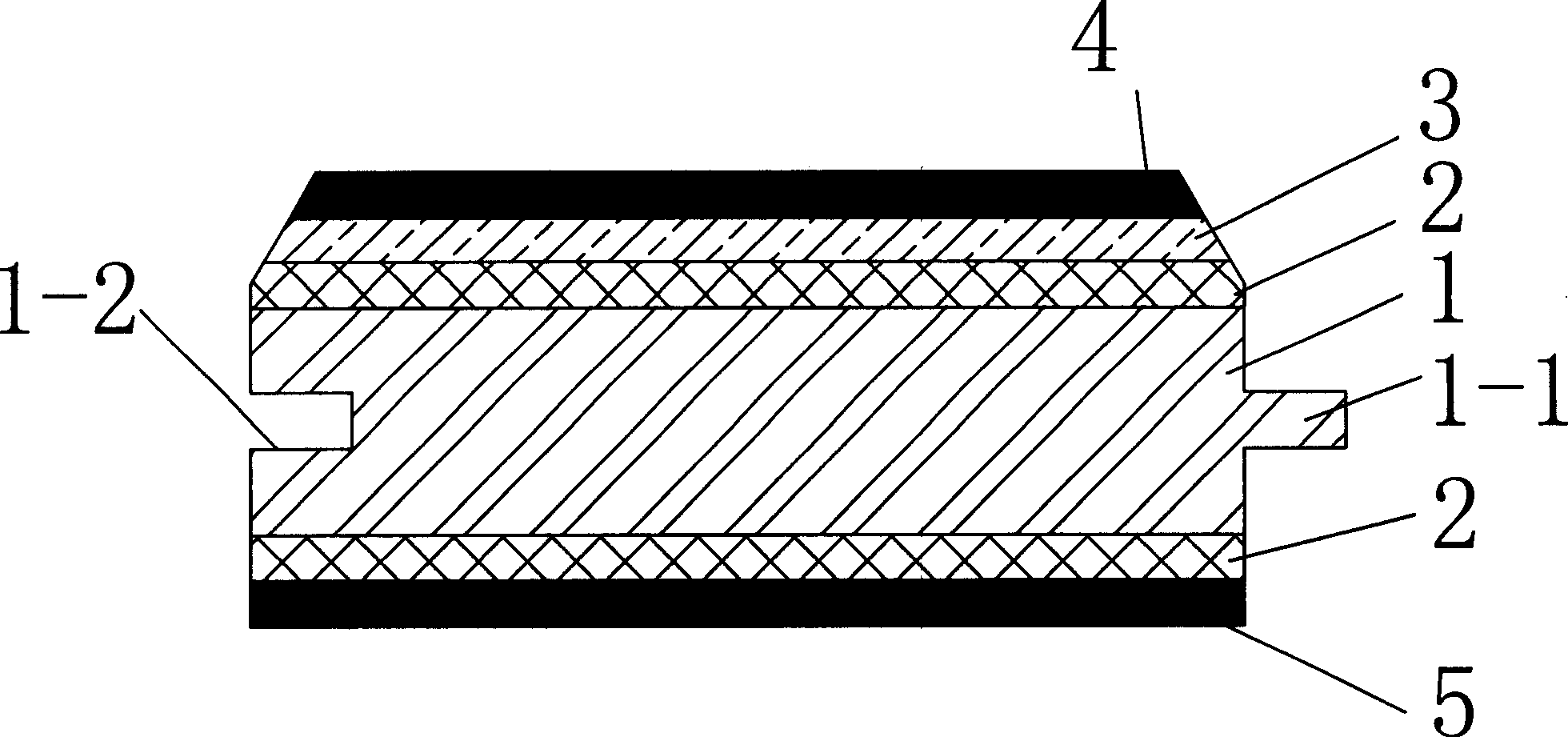

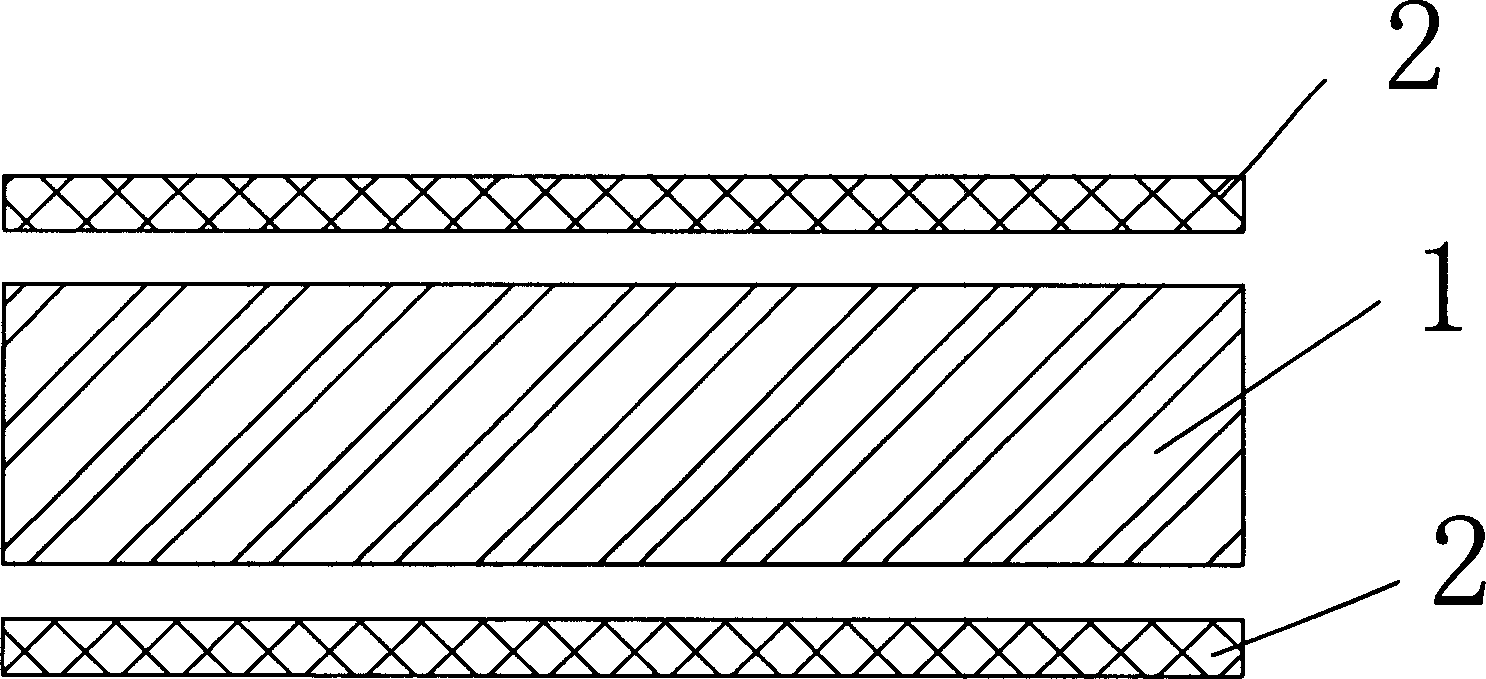

[0017] Such as figure 1 As shown, the wooden floor with impregnated paper multilayer structure includes a balance paper layer 5, a multilayer board 1 and a wear-resistant paper layer 4, and the two ends of the multilayer board 1 are provided with a convex groove 1-1 and a groove 1- 2. It is characterized in that medium / high density fiberboards 2 are provided on the upper and lower surfaces of the multilayer board 1, and the medium / high density fiberboard 2 on one side is provided with a melamine decorative paper layer 3 and a wear-resistant paper layer 4; The medium / high density fiberboard layer 2 on the other side is provided with a balance paper layer 5; the structure after chamfering and pasting the film is as follows figure 2 As shown, the chamfer can be a 45-degree angle or a curved chamfer.

[0018] The balance paper layer 5 is made of melamine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com