Radiator and its making method

A technology of a heat dissipation device and a manufacturing method, which is applied in the directions of cooling/ventilation/heating transformation, electrical components, electric solid devices, etc., can solve the problems such as the heat dissipation efficiency of the heat dissipation device 1 cannot be effectively improved, the flow of the working fluid is disordered, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

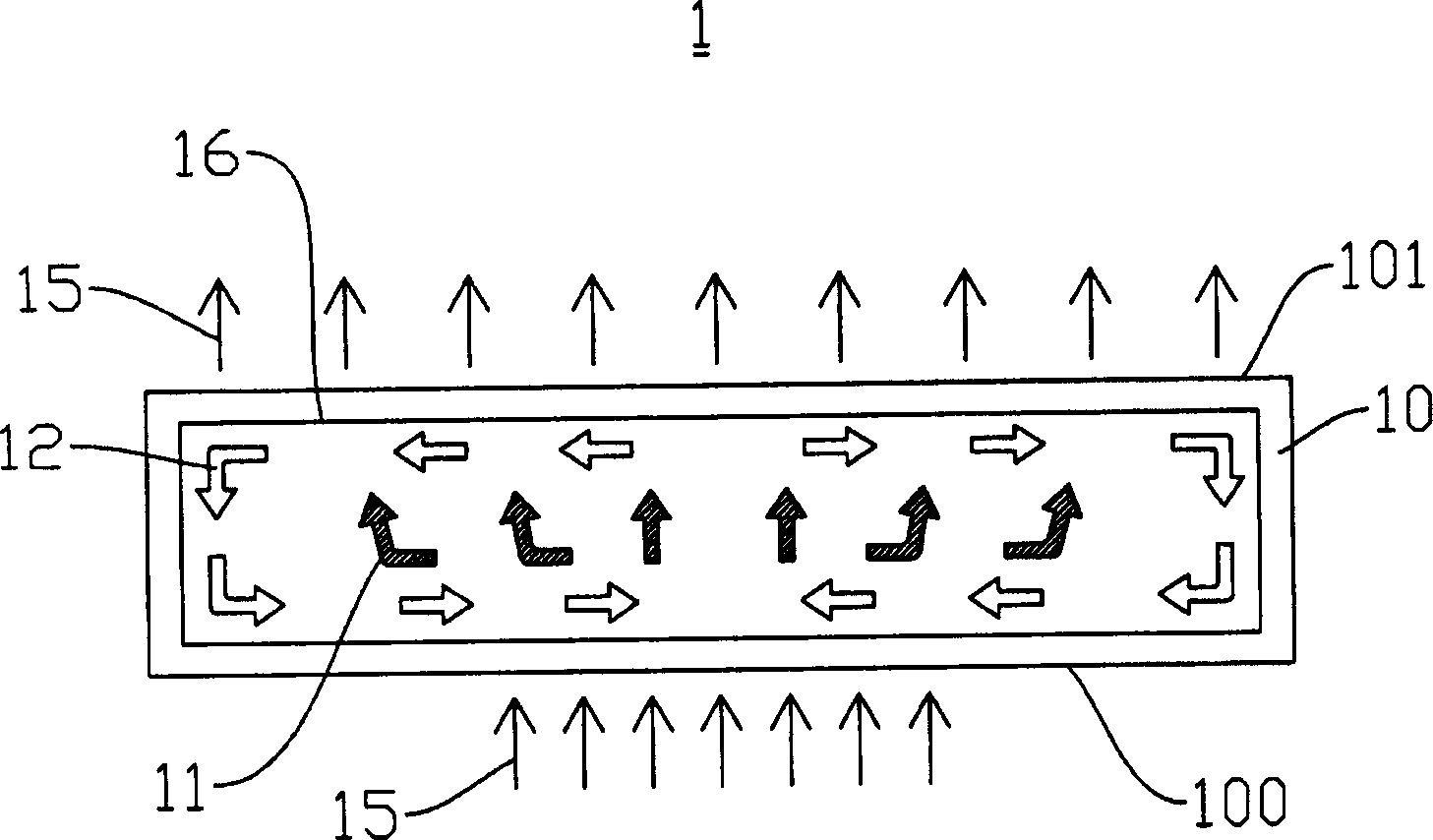

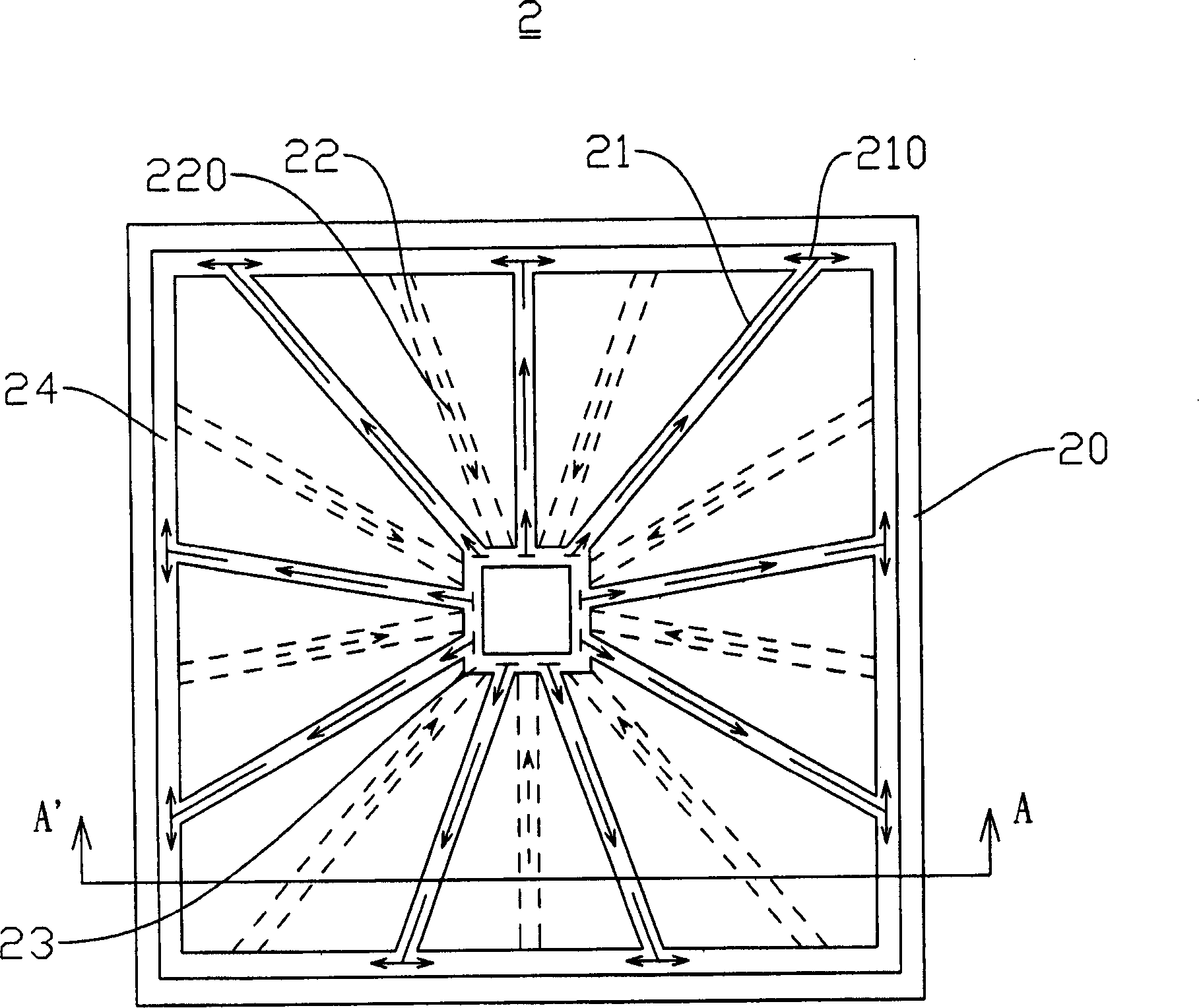

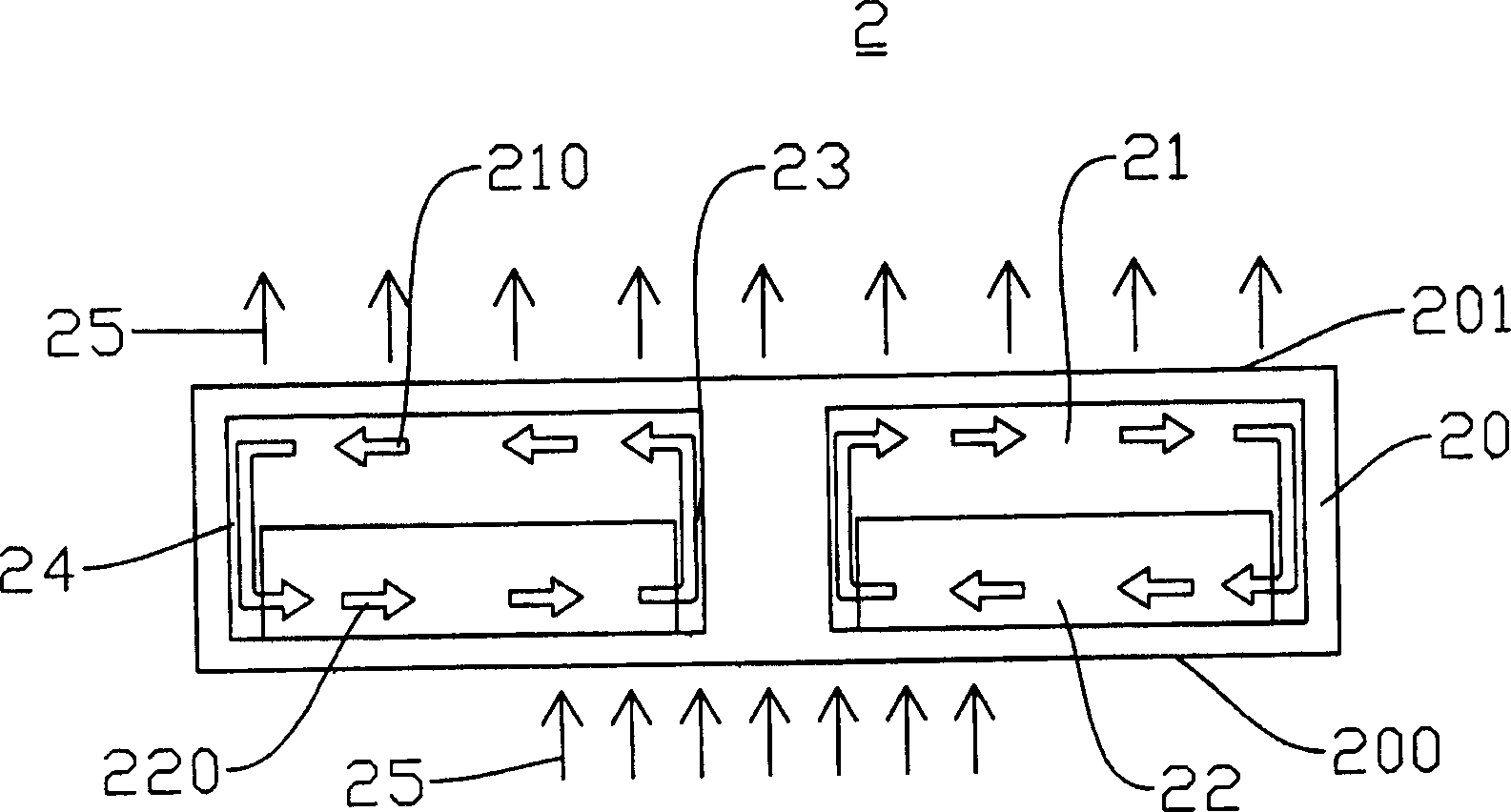

[0043] In order to clearly understand the detailed structure of the heat sink 2 in the embodiment of the present invention, refer to Figure 2A to Figure 2C . Such as Figure 2AAs shown in , the heat dissipation device 2 of the first embodiment of the present invention includes a casing 20, at least one heat dissipation channel 21, at least one return flow channel 22, a first connection channel 23 and a second connection channel 24, wherein the casing consists of Made of metal or non-metal material, it is good for dissipating heat. The heat dissipation channel 21 , the return channel 22 , the first connecting channel 23 and the second connecting channel 24 are all located in the housing 20 , and the housing 20 has working fluid inside. The first connection channel 23 connects one end of the heat dissipation channel 21 and one end of the return channel 22, and the second connection channel 24 connects the other end of the heat dissipation channel 21 and the other end of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com