Heat radiator

A heat sink and cooling fin technology, which is applied in heat exchange equipment, electrical solid devices, semiconductor devices, etc., can solve the problems of complex processing of cooling fins, damage, and failure of heat sinks to form, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

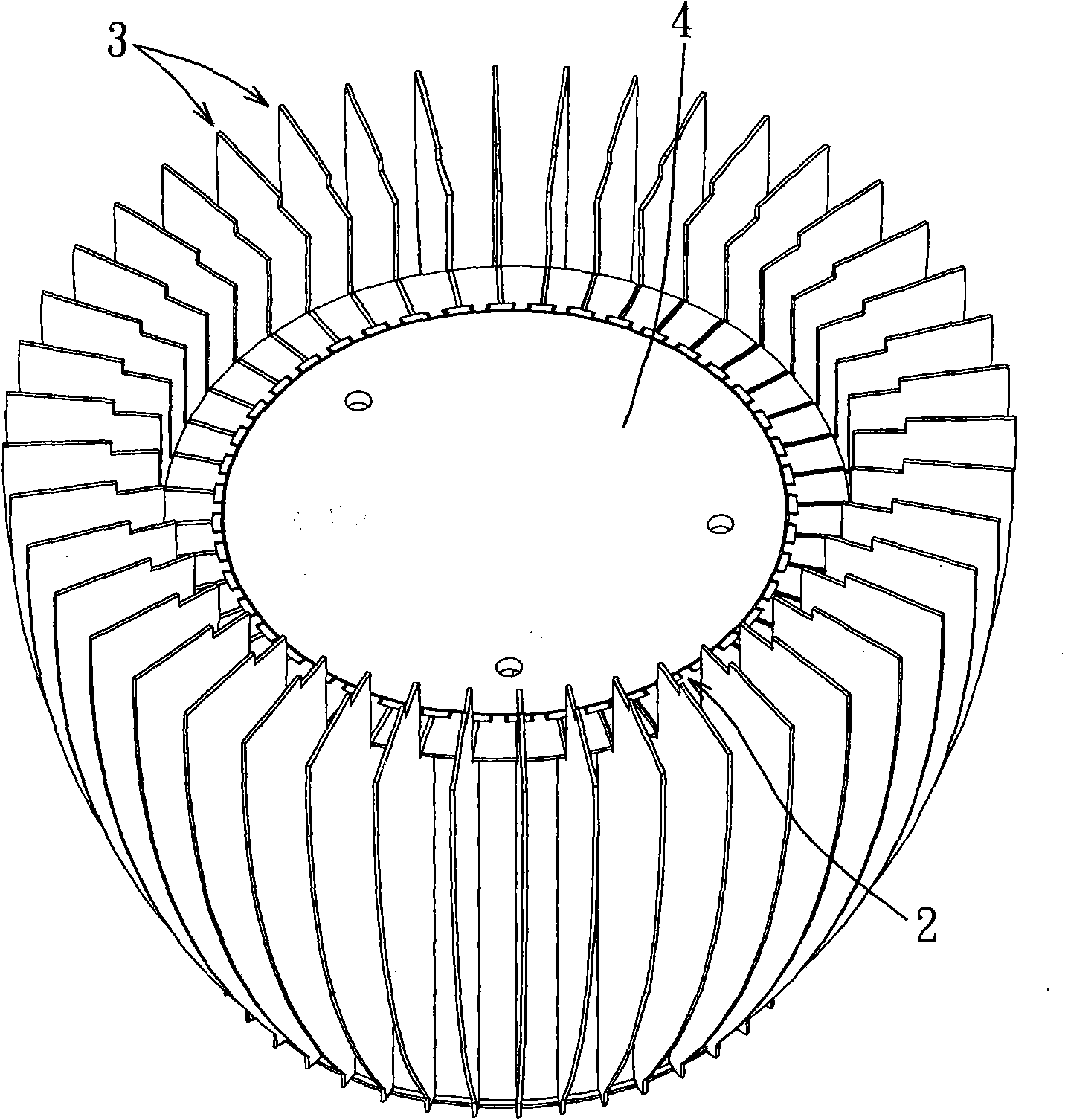

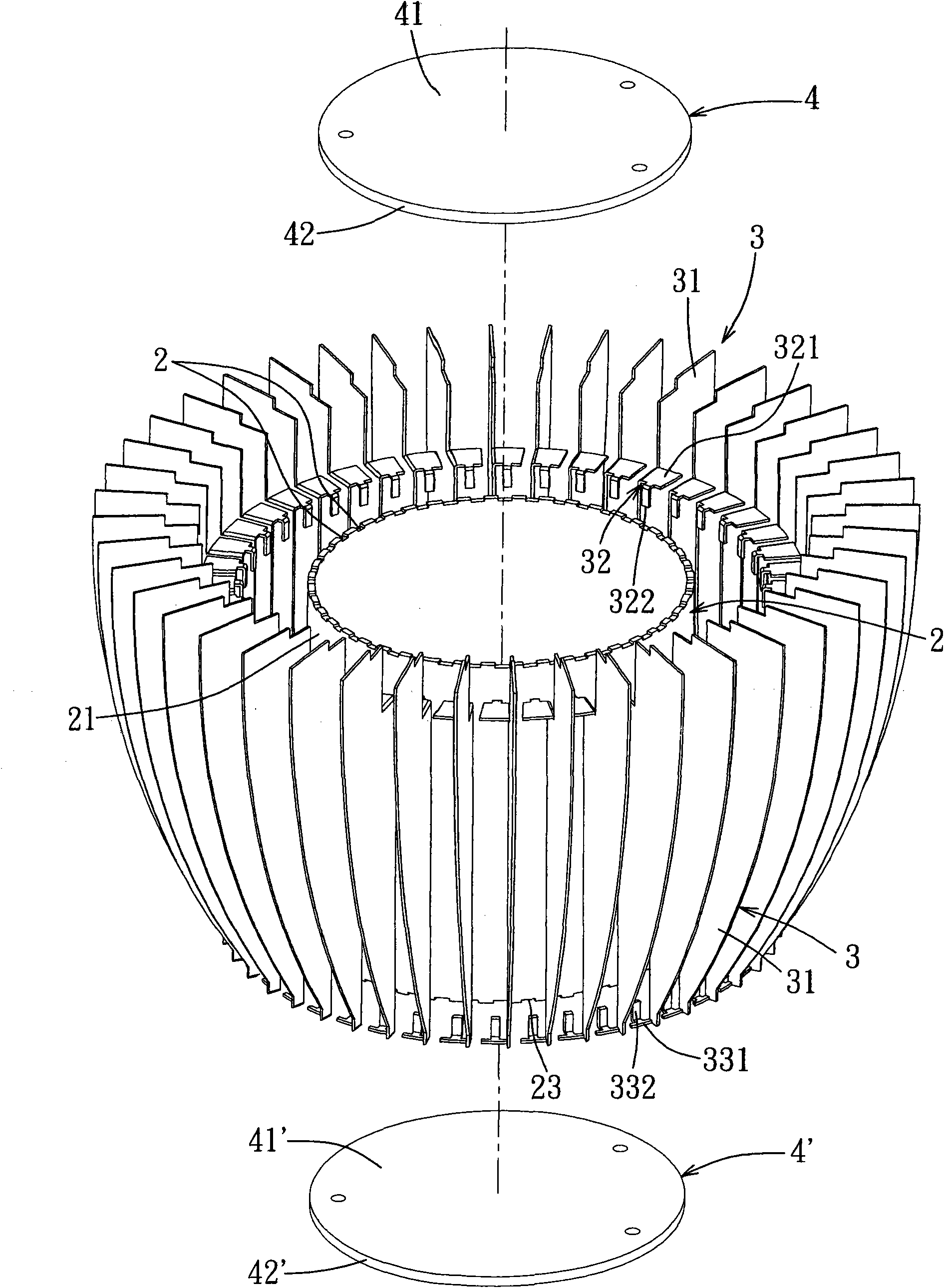

[0023] refer to Figure 1 to Figure 3 , a preferred embodiment of the radiator of the present invention includes a socket 2, a plurality of cooling fins 3, and two fixing plates 4, 4'.

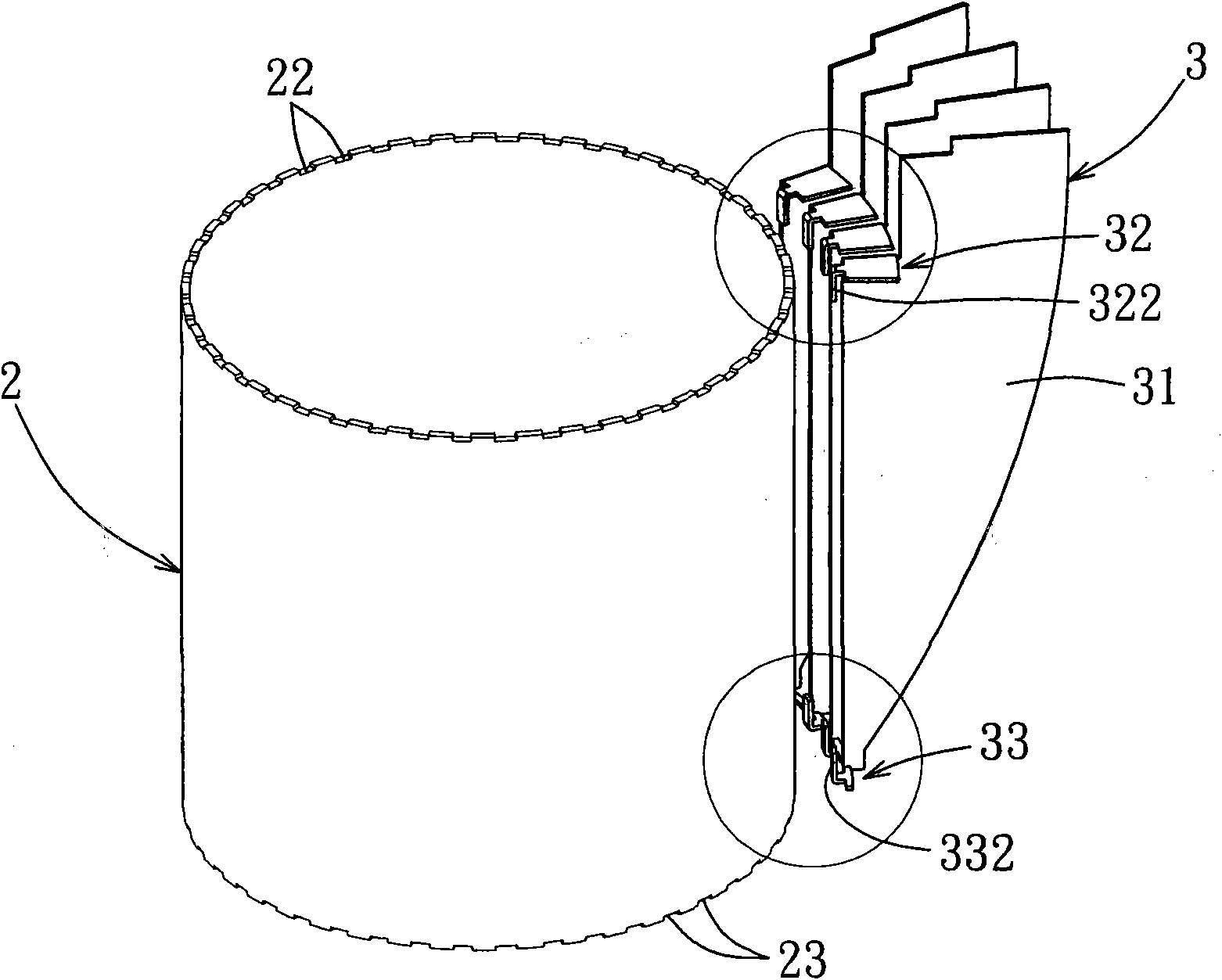

[0024] The socket 2 includes a tube body 21 defining upper and lower openings 211, 212 and an inner peripheral wall 213, a first fixing portion 22 formed on the tube body 21 and adjacent to the upper opening 211, and a tube body 21 formed on the tube body 21 and The third fixing portion 23 is adjacent to the lower opening 212 . In this embodiment, the first fixing part 22 of the receiving seat 2 is a plurality of buckle grooves formed at intervals on the tube body 21 and surrounding the periphery of the upper opening 211, and the third fixing part 23 of the receiving seat 2 is formed at a plurality of intervals. The pipe body 21 surrounds the buckle groove at the periphery of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com