Temperature controllable fluid dynamic simulation test device

A dynamic simulation test and test equipment technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of long period, high cost and inconvenient research work for researching new ship materials and protective coating materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

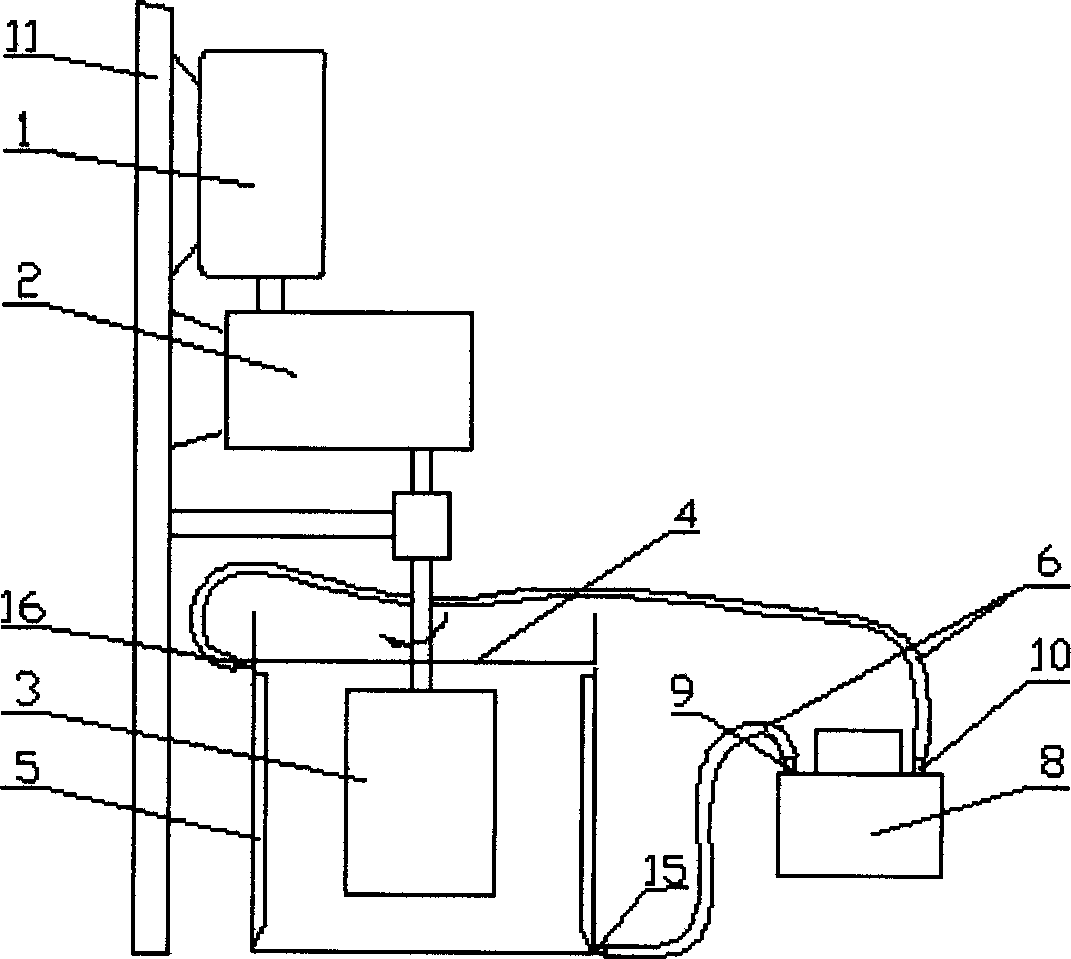

[0026] The motor 1 and the transmission device 2 are fixed on the bracket 11;

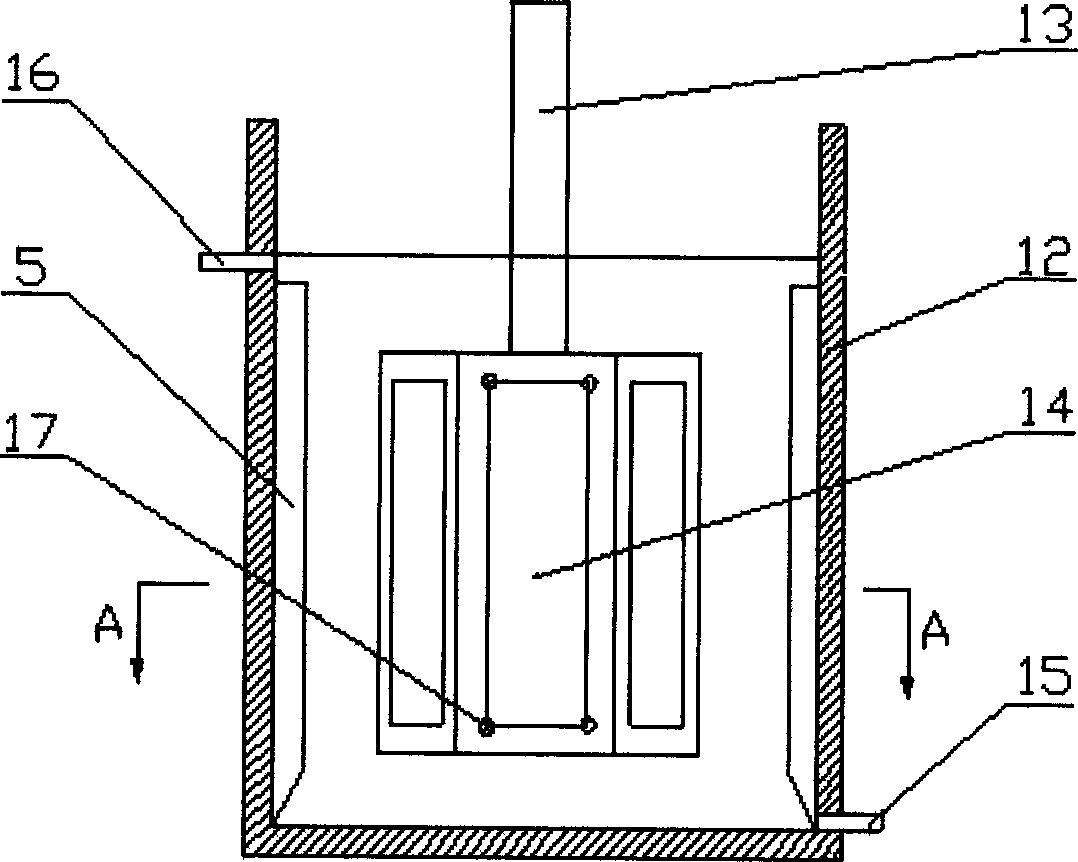

[0027] the rotating drum 3 is coupled to the shaft 13;

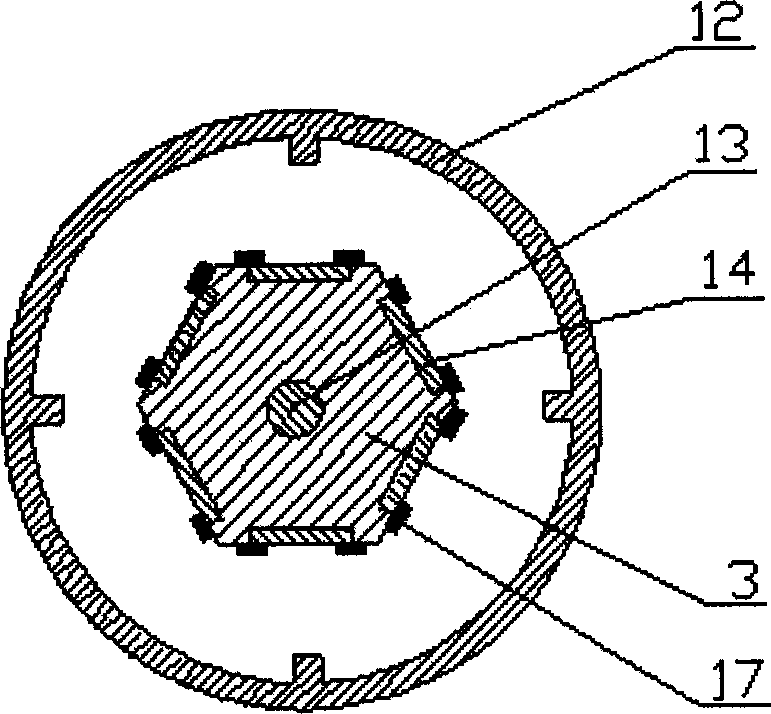

[0028] The rotating drum 3 is a hexahedral prism with a height of 285mm and a side length of 150mm;

[0029] On each prism surface of the rotating drum 3, open a rectangular groove with a size of 120mm×255mm×1mm, and place the sample 14, whose size is 120mm×255mm×1mm;

[0030] The sample 14 on each prism face is fixed by four screws 17;

[0031] The water storage container 12 is made of plexiglass, has a water inlet 15 at the bottom of the container, and has a water outlet 16 at the upper water surface;

[0032] The inner surface of the water storage container 12 is equidistantly inlaid with four baffle plates 5;

[0033] By adjusting the speed of the transmission device 2, the speed of the rotating drum 3 is controlled to control the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com