Method for producing a secondary cell having flat wound electrode body

A technology of spiral electrodes and secondary batteries, which is applied in secondary battery manufacturing, electrode manufacturing, secondary batteries, etc., can solve the problems of deterioration of battery characteristics such as cycle characteristics, failure to increase winding speed, and reduction of winding quality, etc., to achieve Suppression of cycle deterioration, suppression of battery thickness increase, and excellent productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052]

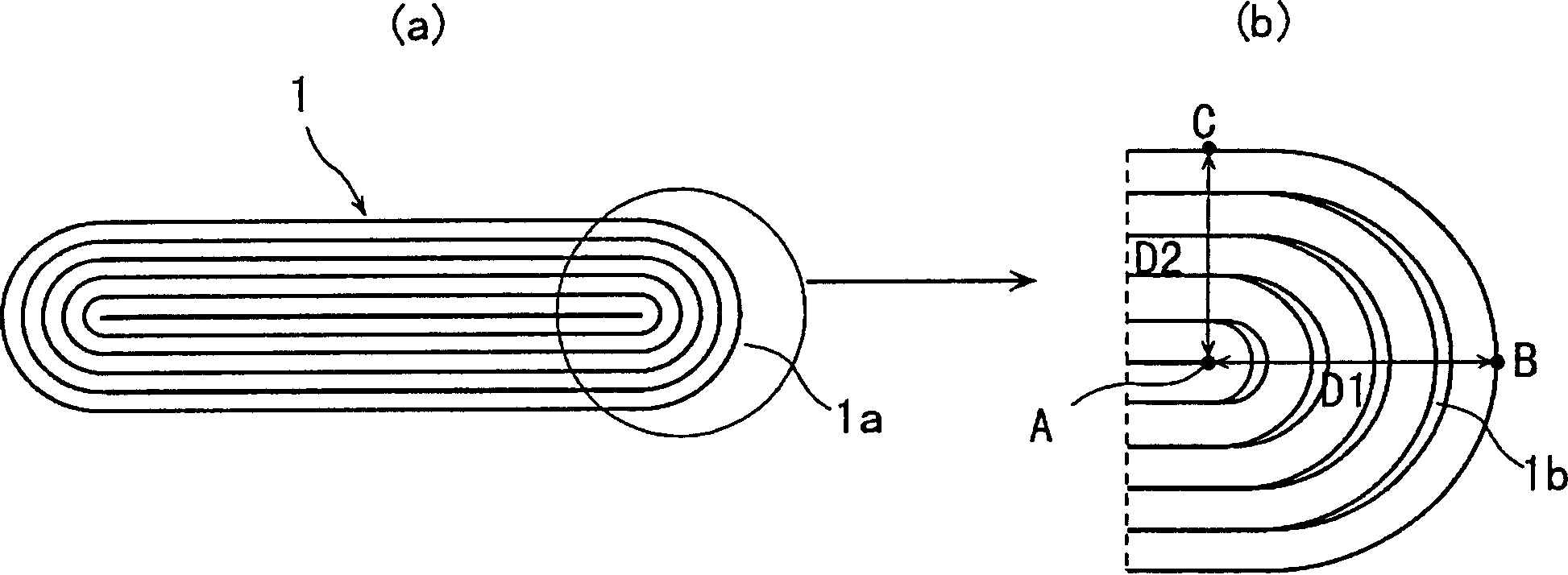

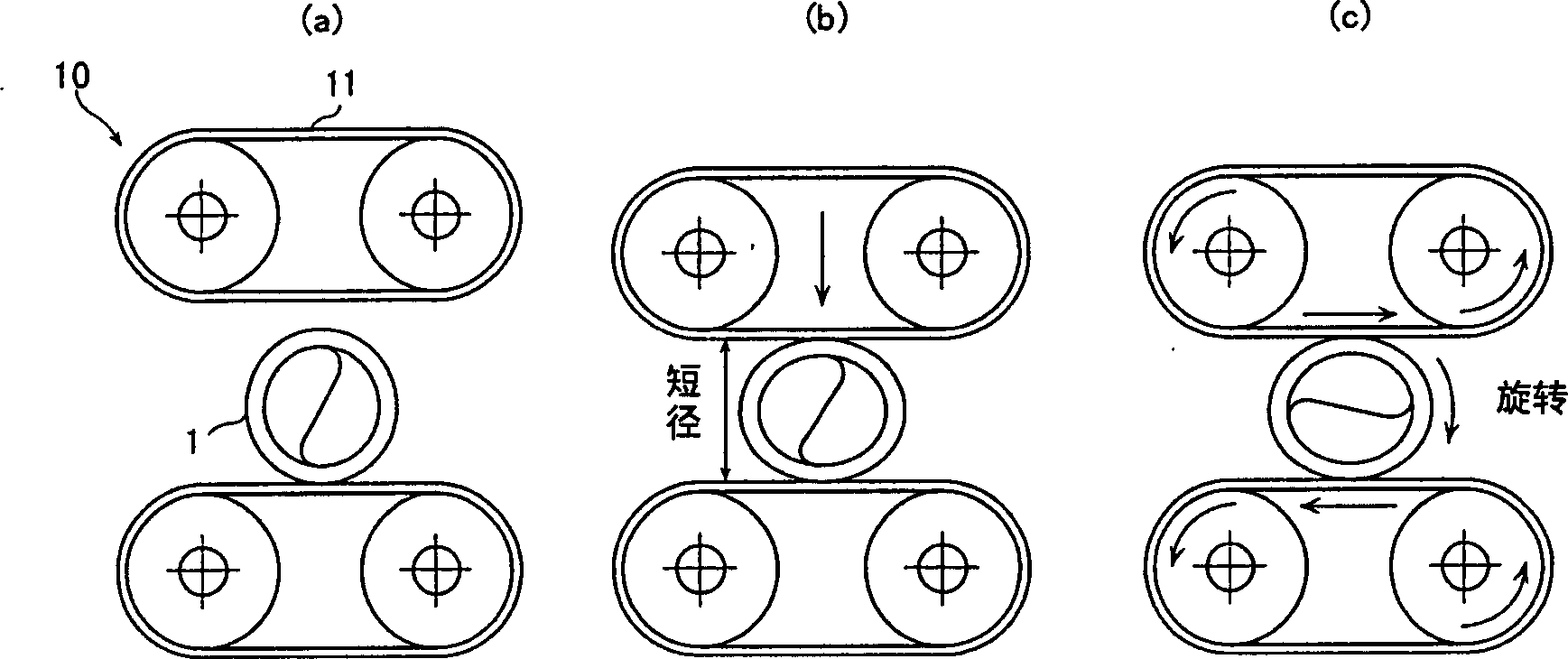

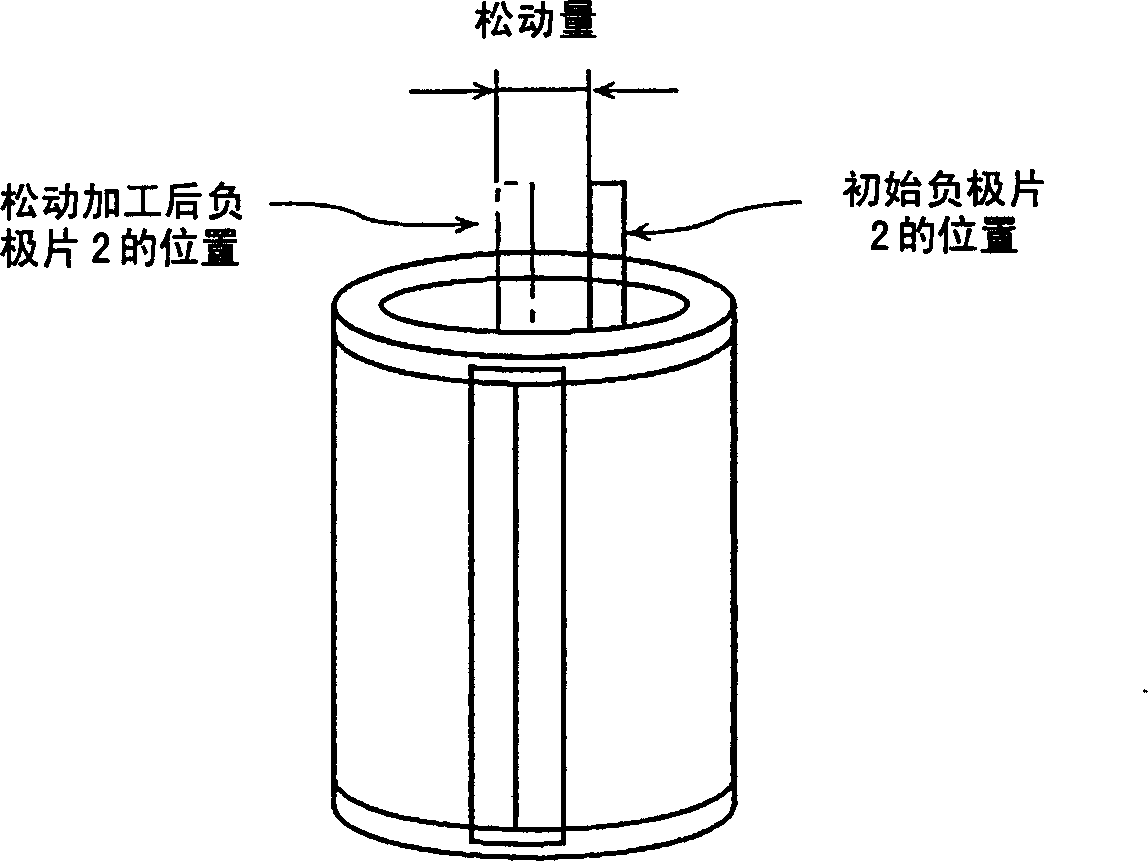

[0053] Using a winding core with a circular cross-section, wind the positive electrode prepared by a known method, the negative electrode with the negative electrode sheet 2 installed, and the separator between the two, then fix the winding end by a tape (tape), remove the winding core, thereby producing a cylindrical electrode body 1 (16.5 mm in diameter). Such as figure 2 As shown, on the one hand, using a loosening processing device 10 having two rotating rollers 11 arranged in parallel, the electrode body 1 is pushed into a rough ellipse with a minor diameter of 15.0 mm (about 91% of the original diameter) in cross section. On the other hand, the electrode body 1 is rotated (loosening process) in the same direction as the winding direction. at this time, image 3 The movement distance (looseness) of the negative electrode sheet 2 shown in is 6.2 mm.

[0054] Thereafter, after pressing in a direction perpendicular to the width direction of the negative electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com