An apparatus for producing ozone by electrolysis

An ozone and electrolyte membrane technology, used in electrolysis components, electrolysis process, oxidized water/sewage treatment, etc., to prevent the increase of electrolysis voltage, realize operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments according to the present invention are described in detail below with reference to the accompanying drawings.

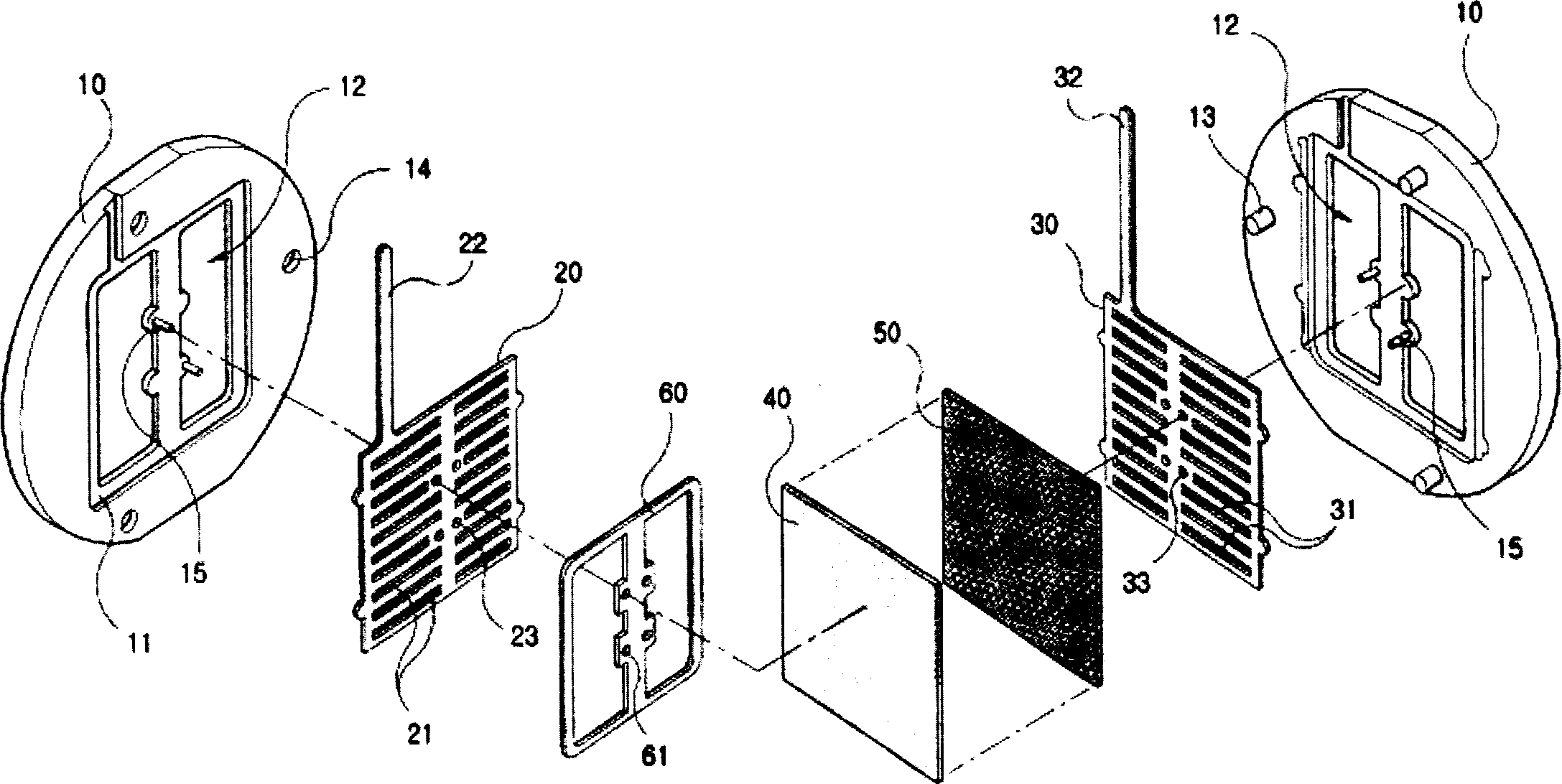

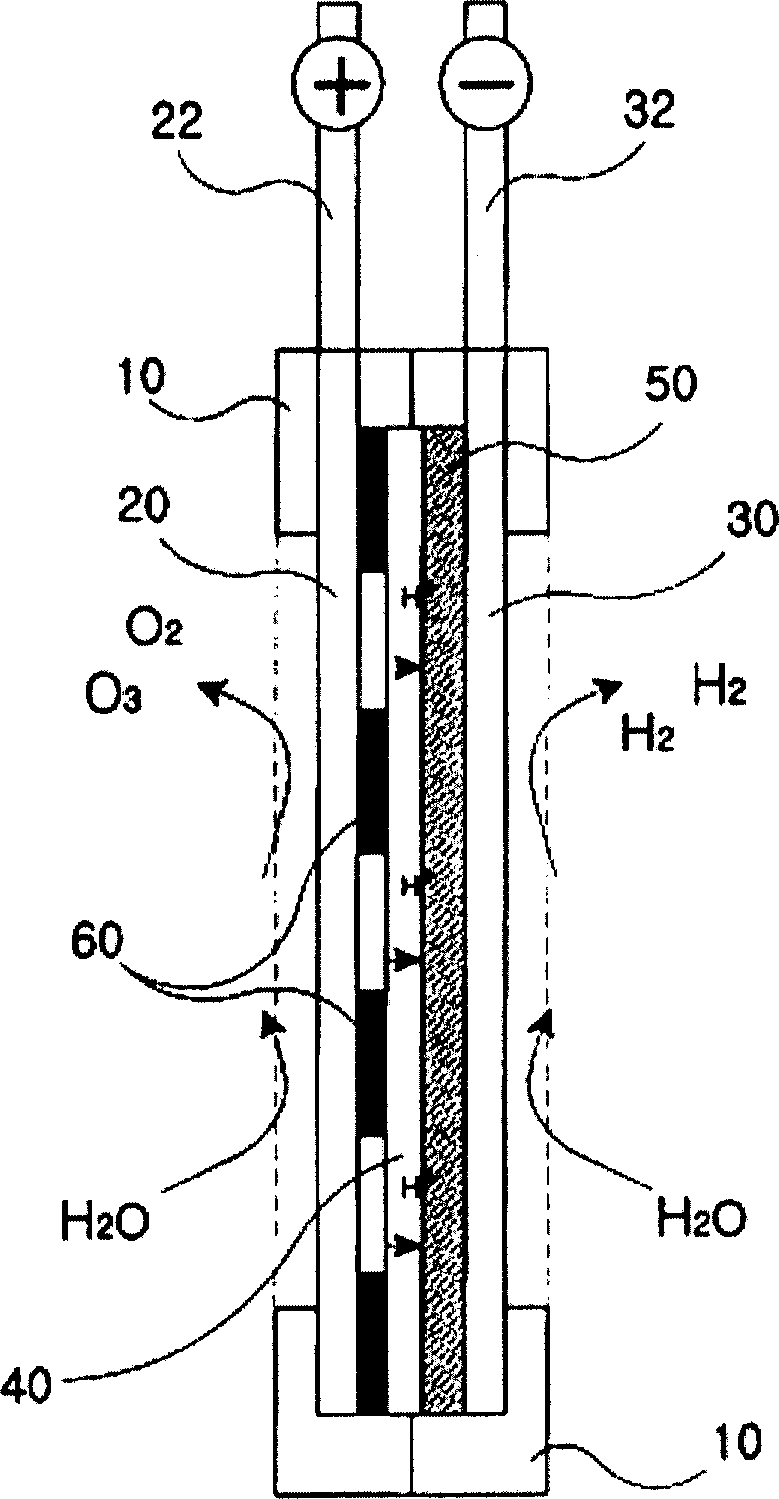

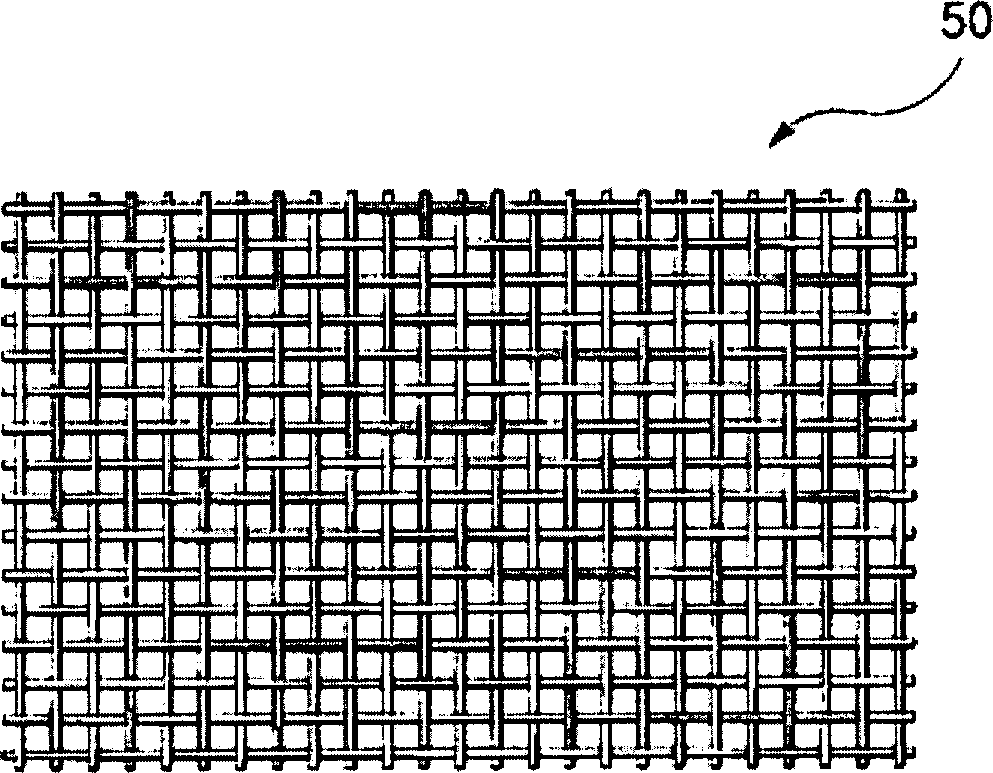

[0028] figure 1 Illustrates a perspective exploded view of an apparatus for producing ozone by electrolysis, also referred to as an "ozone generator", according to an embodiment of the present invention. figure 2 for figure 1 Assembly drawing of the ozone generator in . see figure 1 with 2 , the ozone generator of the present invention includes a pair of frames 10 facing each other, and an anode 20 and a cathode 30 installed between the pair of frames 10 oppositely. A solid polymer electrolyte membrane 40 is provided between the anode 20 and the cathode 30 for transferring hydrogen ions formed in the electrolysis process. In addition, an auxiliary electrode 50 is provided between the cathode 30 and the solid polymer electrolyte membrane 40 so that scale can be formed on the surface of the auxiliary electrode 50 . A separator 60 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com