Adjustable double-sided adhesive tape cutting and transferring unit

A technology of double-sided tape and transfer device, which is applied in bandages, medical science, clothing, etc., can solve the problems such as the limitation of spacing adjustment between two double-sided tapes, the inability to increase the running speed of the production line, and the impact on production efficiency and economic efficiency. The effect of transfer stability, adjustment and maintenance, and easy adjustment and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

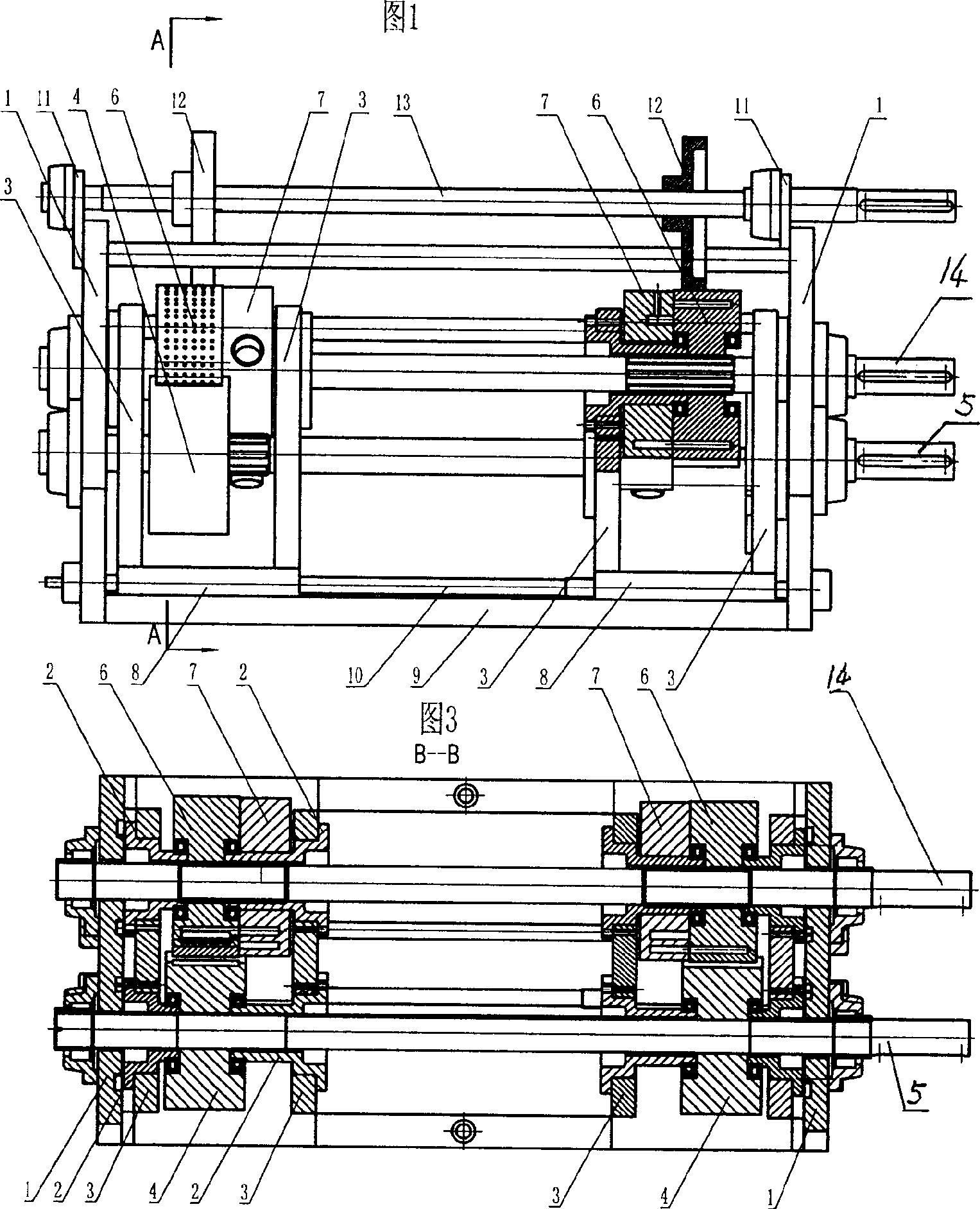

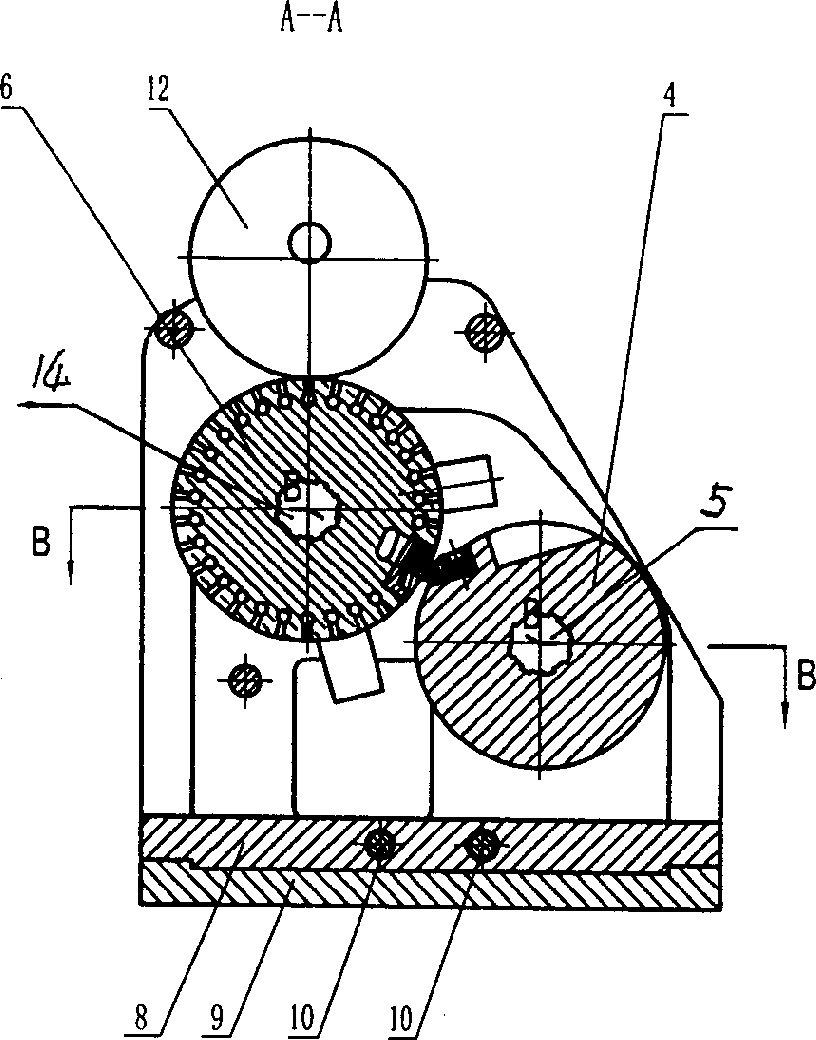

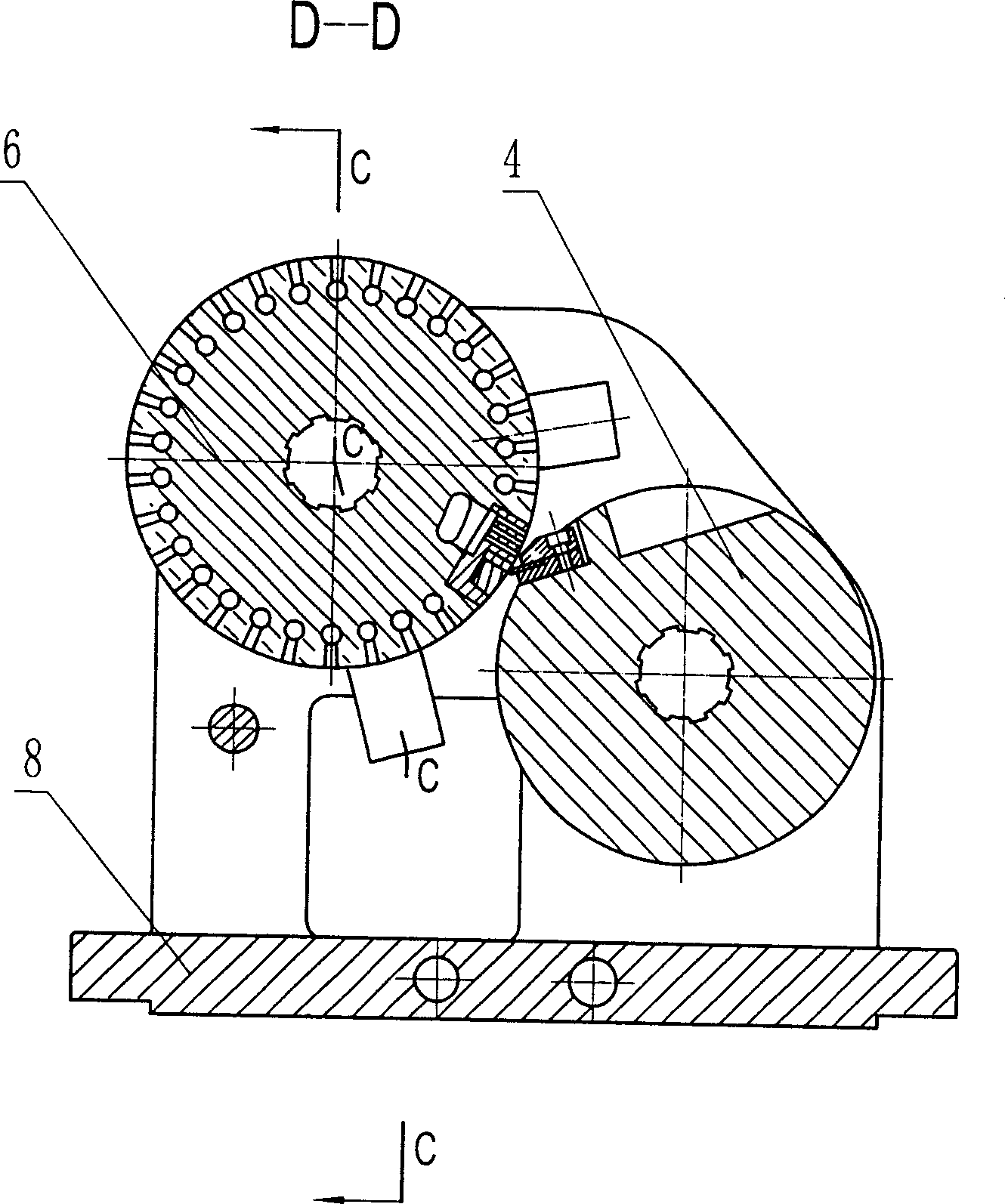

[0031] See Figure 1, figure 2 As shown in Fig. 3, the adjustable double-sided tape cutting transfer device includes a frame, two sets of double-sided tape cutting mechanisms arranged symmetrically, two sets of suction valves 7 and bottom rollers 6 corresponding to the two sets of double-sided tape cutting mechanisms. Frame is made up of horizontal frame bottom plate 9 and two vertical frame side plates 1; Tool rest pulling screw rod 10 is housed in the horizontal knife rest bottom plate 8, and the two ends of knife rest pulling screw rod 10 are connected with frame side plate 1 respectively.

[0032] Two movable knife rests are correspondingly installed in the frame, and the movable knife rests are composed of a horizontal knife rest bottom plate 8 and two vertical knife rest side plates 3, between the bottom surface of the horizontal knife rest bottom plate 8 and the horizontal frame bottom plate 9 For concave and convex groove fit, see Figure 4 , Figure 5 .

[0033] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com