Microparticle containing silicone release coatings having improved anti-block and release properties

A technology for isolating coatings and particles, which can be used in coatings, adhesives, thin material processing, etc., and can solve the problem of expensive silicone materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

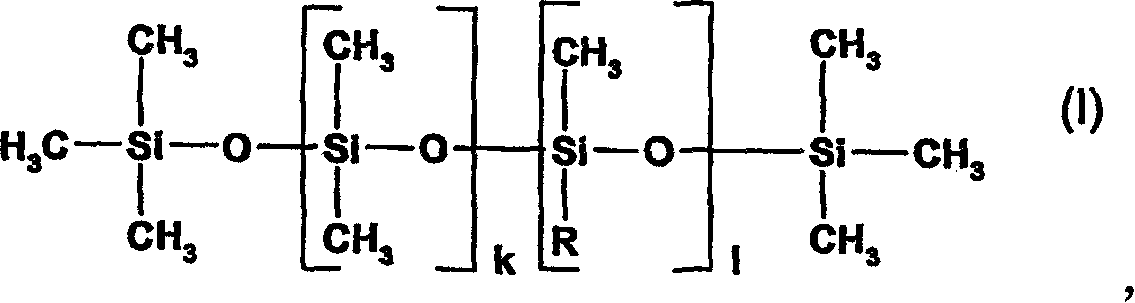

[0120] The starting composition of the isolation coating is:

[0121] 60 parts by weight of curable epoxy polyorganosiloxane compound VI, wherein n is 20

[0122] 30 parts by weight of polyorganosiloxane of compound VII, wherein r is 220

[0123] 10 parts by weight of the polyorganosiloxane compound VIII, wherein p is 200, q is 3

[0124] 2.5 parts by weight of cationic initiator

[0125] 1-3 parts of polymer microspheres

[0126] The photoinitiator used in the test compositions was available from Rhodia Corporation as Silcolease(R) UVCata 211, a cationic photoinitiator activated by ultraviolet radiation. Polymer particles are commercially available from Micro Powders Inc under the name FLUO HT(R) polytetrafluoroethylene (PTFE) microspheres. Polymer microspheres were prepared as a dilution in formula (VII), which constituted 33% by weight of the weight of formula (VII).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com